Mannington Mills

June 23, 2025

What Are Compression Ratios and What Do They Tell Us About Compressor Performance?

June 25, 2025CASE STUDY:

KAISHAN USA AND AIR & HYDRAULIC HALT SAUSAGE MANUFACTURER’S $5,000-A-MINUTE PRESSURE DROPS

The Situation

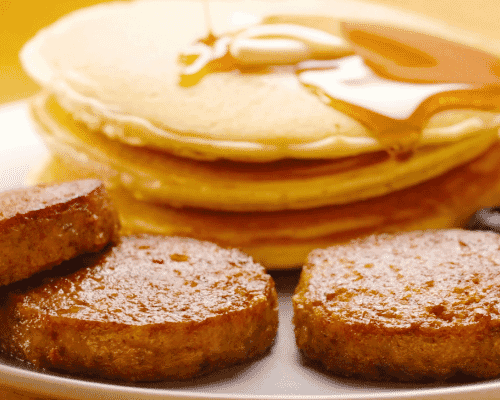

Swaggerty’s Farm has been making premium pork sausage for nearly a century. The company operates at least two shifts per day, keeping its compressed air system in operation 24/7. “Seven lines and not a one runs without air,” according to Steve Douglas, who runs the maintenance and parts operation at Swaggerty’s. Compressed air is one of the company’s major expenses, he added.

The Challenge

Swaggerty’s had two aging 50-HP compressors that were not meeting all its needs and weren’t very efficient. Pressure drops slowed the lines down and cost $5,000 a minute.

That’s $300,000 per hour. Or $7.2M per day to you and me.

Plus, the company waited days or weeks for replacement parts, paying to rent units to keep the operation going.

“For what we were spending and losing, we were better off with a new compressor,” Steve said.

The Solution

When Steve reached out to Rick LaFollette, general manager at Air & Hydraulic Equipment, an independent Kaishan distributor in Chattanooga, TN, he originally thought he needed a 100-HP compressor or even larger. But he asked Rick to perform an audit.

Rick’s analysis revealed that a 75-HP rotary screw air compressor could handle the workload. After pricing several well-established brands, Steve selected a Kaishan 75-HP KRSD direct-drive compressor with a variable-speed drive.

The Results

- “IT’S DONE EVERYTHING WE ASKED”: “I don’t know of another compressor that I could have put back there that would have done any better or held up any better,” Steve said.

- VSD ENERGY SAVINGS: Replacing the two aging fixed-speed energy hogs has been a significant saving, Steve says. Although he is not able to quantify the amount, “We were pulling more then than we pull now.”

- NEXT-DAY REPLACEMENT PARTS: No matter what brand or type of equipment you buy, you’re going to need parts, Steve says. So, when Kaishan and Rick managed a one-day turnaround on a minimum pressure valve, he was ecstatic. “The support you get with it” is the number one reason Steve has already signed up for an additional Kaishan unit in another part of the plant. Two new 50-HP units are planned in late summer 2025.

- FANTASTIC SUPPORT: Air & Hydraulic Equipment supplied a new compressor, as well as a new dryer and new piping to boost the compressed air system’s distribution capacity. Ever the realist, Steve accepts that issues will arise with a machine running 24/7. But he knows he can count on Rick and the Air & Hydraulic Equipment team. “I feel confident that I can get it serviced if something did happen to it.”

“I don’t know of another compressor that I could have put back there that would have done any better.”

— Steve Douglas, Maintenance Manager, Swaggerty's Farm

More case studies:

Random stat or

customer quote

textXXtext

text