Your Gameplan for Optimizing Rotary Screw Air Compressors for Maximum Energy Savings

April 16, 2025

Your Rotary Screw Compressor Airend: Where the Magic Happens

April 30, 2025Ten Key Facts You Need to Know About Rotary Screw Air Compressor Motors

Kaishan USA | April 23, 2025| Uncategorized

Our independent distributor, Iowa Pump and Compressor, recently installed this KRSP2 compressor, which is driven by a large 350-HP motor.

A motor is the driving force behind a rotary screw air compressor. So much so that the motor’s capacity is used to describe the compressor’s. After all, we call them 25-HP and 50-HP compressors.

The motor's horsepower rating tells us how much work the compressor can perform—the higher the motor's horsepower, the greater the compressor’s capacity.

You need that power to generate all the energy needed to deliver compressed air at the required flow and pressure.

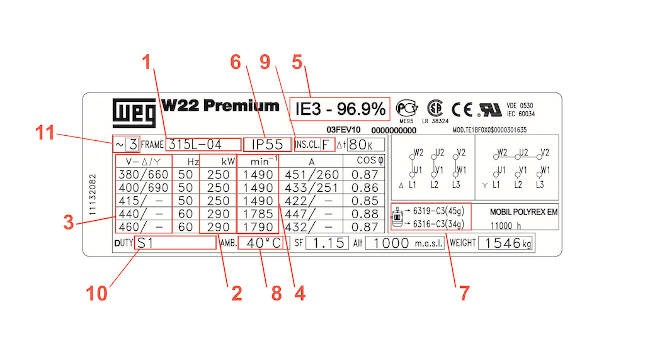

The nameplate on your compressor motor gives you all the information you need to operate the motor within established parameters. One key piece of information is the voltages the motor can be wired to, especially if you have a main motor offering several voltage options. (Courtesy, Plant Engineering.)

It’s All in a Nameplate

According to Plant Engineering magazine, all the critical information is on your air compressor motor nameplate, including the following data:

- Frame size

- Power (in HP or kW)

- Voltages, including both a delta (low-voltage) and a star (high-voltage) connection

- Motor speed (RPM)

- Efficiency standard, usually IEC or NEMA

- Ingress protection (IP) rating, protection against foreign material entering the motor

- Service factor, the motor’s power rating

As a result, it helps to know a lot about air compressor motors when acquiring, operating and maintaining an air compressor. Following are ten critical pieces of information that will help. We’ll start with the revelation that the main motor is not the only motor in your compressor.

1. There’s More Than One Air Compressor Motor

Rotary screw air compressors have secondary motors driving key components like cooling the fans used in air-cooled units. Water-cooled machines also have very small motors, keeping the hot air circulating out of the package. We’ll discuss the types of cooling approaches below.

The different uses of these motors are spelled out in the compressor’s CAGI sheets. For more on reading and interpreting the information in these important documents, read our blog post, “A Beginner’s Guide to Reading Rotary Screw Compressor Performance Curves.”

So what kinds of motors are used in rotary screw air compressors?

2. Different Types of Air Compressor Motors Are Used

While most rotary screw air compressors currently use traditional induction motors, permanent magnet motors are considered the wave of the future. Here’s a brief description of each.

Induction Air Compressor Motors

Induction motors use alternating current to convert electrical energy into mechanical energy through electromagnetic induction. Since Nikola Tesla invented them more than a century ago, they have been applied in a wide range of applications because they are efficient, reliable and flexible.

They are asynchronous—the rotor spins more slowly than the magnetic field created by the stationary stator’s wire coils, causing a lag or slip.

Single- and three-phase induction motors are used most often in industry today, especially in air compressors. However, many manufacturers are considering permanent magnet motors because of their efficiency, small size and greater reliability.

Permanent Magnet Air Compressor Motors

Unlike induction or asynchronous motors, permanent magnet motors rotate at the same speed as the stator’s magnetic field, so there is no slip.

The PM motor’s magnets are made of rare earth elements and are at least twice as powerful as those used in induction motors, allowing them to exceed the power density efficiency of the more traditional induction units. They are more expensive as a result.

You can spin the motor at higher and lower speeds than an induction motor, improving the turndown capability. They are designed to work with variable-speed drives.

And while there have been some notable failures, we believe PM motors are the wave of the future. The electric vehicle industry is all in on PMs, most likely leading to a higher adoption rate as the obvious advantages overcome the initial skepticism stemming from the early failures.

PM motors are the only way the industry will be able to comply with the evolving global efficiency standards.

3. You Can Measure Air Compressor Motor Efficiency with Different Standards

Several different groups or agencies have developed efficiency standards for motors:

- The National Electrical Manufacturers Association

- The International Electrotechnical Commission

- Guobiao (GB), China’s national efficiency standard.

Not surprisingly, NEMA ratings are commonly used in the Americas, while IEC standards are followed in Europe and GB is more commonly enforced in Asia and many other international locations.

4. Air Compressor Motors Are Rated for Protection/Insulation Class

Insulation class establishes the temperature that your motor can endure. Class F is the most common rating used in motors above 5 HP, while Class H is less common, used for heavy-duty, hot or high-altitude conditions.

The key thing to remember is that if you go too far beyond the rating, you’ll risk burning out the motor. The rule of thumb is that every 10°C you operate a motor above the insulation rate cuts the insulation’s service life in half, according to Machine Design magazine.

5. Air Compressor Motor Enclosures Protect Your Equipment

All our compressors are equipped with totally enclosed, fan-cooled motors, preventing debris and contaminants from entering the unit. In addition to cooling the unit, the fan boosts the efficiency and equipment life of TEFC motors compared with open drip-proof motors.

6. The Service Factor Measures the Resilience of Your Air Compressor Motors

The service factor is the power rating a motor can handle for short periods. It helps you know how far beyond the rated capacity you can expect to run the motor. A typical reading of 1.15, for instance, indicates you can operate the motor at 115% of its capacity for short periods.

7. Your Air Compressor Motors Needs To Be Grounded

For most variable-speed drive applications, the motors must be grounded, usually with a grounding brush, a consumable item that often needs replacement. You’ll need to work with your distributor to replace it properly.

8. Supplemental Air Compressor Motors Play a Crucial Role in Cooling

Cooling is critical in a rotary screw air compressor. Heat is the sworn enemy of an air compressor. It will shorten the life of the oil and the compressor itself. It will increase all your costs, including electricity bills and maintenance expenses. It can even result in poor air quality, including pass-through of oil and water.

There are two types of auxiliary motors in your compressor that assist in cooling:

- Air cooling. Fans push air across a fin-and-tube air compressor to remove heat and moisture. The compressor is usually designed assuming the doors are shut, so it’s essential not to remove the doors or enclosures. The motor for the oil cooler is usually the largest of these auxiliary motors.

- Liquid cooling. While a pump does most of the work in liquid cooling, a small fractional-horsepower motor drives a fan that pulls air out of the package to ensure heat buildup does not damage the main motor and the electronics. Our new portable unit has liquid cooling on its variable-speed drive and electric motor. The objective is to provide extra cooling to increase efficiency and prolong service life.

Visit our blog post to read about “All the Ways Heat Gets into Your Compressed Air System (And How To Get Rid of It)."

9. Bearings Ensure the Performance and Longevity of Air Compressor Motors

We use premium quality SKF bearings machined to tight tolerances in all our compressors. They absorb the radial and axial loads from the rotors, ensuring the performance and the life of the airend.

10. Air Compressor Motors Connect to the Airend in Several Different Ways

Rotary screw air compressors have a main motor driving the rotors. Most have electric motors:

- Direct-drive motors are directly coupled to the airend. A coupling usually connects the main motor to the airend (although some companies use a gearbox or other device between the motor and the airend to eliminate the need for couplings).

- Belt-drive units, such as our KRSB belt-drive rotary screw air compressors, are driven by a belt-and-pulley system.

Our KRSB belt-drive rotary screw air compressors are driven by a belt-and-pulley system.

A related issue is the drive function fulfilled by variable-speed drives. Many companies have saved significant amounts of energy by using rotary screw air compressors equipped with VSD technology. And energy savings are not the only benefit. VSD compressors can earn rebates, allow soft starts and offer better control of your compressed air system. They are also an energy-efficient way to address rapid cycling.

Companies have saved significant amounts of energy using rotary screw air compressors equipped with VSD technology.

But they are not a good choice at the extremes—we encourage customers not to use a VSD compressor when the machine runs at 20% of its total capacity most of the time or more than 80%. At the higher ranges, they are not cost-effective because there are energy losses associated with the drive itself, and the savings will be minimal. At usage rates below 20%, the compressor will not get warm enough to evaporate moisture in the air, creating the potential for rust and corrosion.

For more on the pros and cons of VSDs, see our blog post, “How Variable-Speed Drive Rotary Screw Air Compressors Save You Money.”

As with most motor-related issues, it’s wise to seek help from a knowledgeable compressed air consultant when determining whether a VSD is right for your operation.

Get Expert Help from a Local Professional

Your local compressed air consultant is an essential resource who can address any concerns about air compressor motors. Our nationwide network of independent distributors, can provide on-site help and consultation on almost any issue. These factory-trained air compression experts have deep expertise in addressing air compressor motors or broader compressed air system concerns.

We choose to partner with these independent, local businesses because there’s no better way to ensure you have expert guidance, fast response times and personalized support tailored to your needs. They don't just sell compressors—they build relationships that ensure you get the right system, reliable service and quick access to parts when you need them most.

So, when you buy through Kaishan, you're getting more than a product—you're getting a local partner, a compressed air expert who cares about your business and seeing it succeed.

Key Takeaways

Ten Key Facts You Need to Know About Rotary Screw Air Compressor Motors

1. There’s More Than One Air Compressor Motor

2. Different Types of Air Compressor Motors Are Used

3. You Can Measure Air Compressor Motor Efficiency with Different Standards

4. Air Compressor Motors Are Rated for Protection/Insulation Class

5. Air Compressor Motor Enclosures Protect Your Equipment

6. The Service Factor Measures the Resilience of Your Air Compressor Motors

7. Your Air Compressor Motors Needs To Be Grounded

8. Supplemental Air Compressor Motors Play a Crucial Role in Cooling

9. Bearings Ensure the Performance and Longevity of Air Compressor Motors

10. Air Compressor Motors Connect to the Airend in Several Different Ways

Let Us Help

Understanding how your air compressor motor works is extremely helpful in selecting, operating and maintaining a rotary screw air compressor. If you need help with motor-related issues or any other compressed air concerns, get in touch with the experts at Kaishan. Contact us today.

Listen to the Podcast Version

The Basics of Compressor Motors

Welcome back to the Big Dog podcast, everyone! We're hyped to be with you today.So, let's get into it, Lisa. The motor on a rotary screw air compressor—it's the heart of the whole system. I mean, we even describe compressors by their motors, right? Like a 25-horsepower compressor, or, say, a 50-HP unit.

Yeah, that's interesting because, you know, most people probably just think of the compressor as one big machine, and don’t realize it’s the motor that's really driving everything.

Exactly. The horsepower, or HP, essentially tells us how much work the compressor can handle. More horsepower means more air at the flow and pressure you need. Like the 350-horsepower unit our distributor, Iowa Pump and Compressor installed—it’s a beast, cranking out massive amounts of compressed air. But it all comes down to the motor.

But there’s more to it than just power, right? Like, the nameplate on that motor—it’s got all the critical details, doesn’t it?

Yeah, that little nameplate is like a cheat sheet for the motor. You’ve got info like the frame size, voltage, RPMs, efficiency standards—it’s all, it’s all there. Knowing how to read that is key when you’re setting up or maintaining the system.

And there’s even stuff about voltage and wiring on there, isn’t there? That sounds super important, especially if you’re switching between, like, different setups.

Totally. A lot of motors come with dual voltage options, so understanding that can save you a ton of headaches. And it’s not just about operation—it’s also about keeping the motor within its limits so you don’t burn it out.

Makes sense. But what about protecting these motors in the first place? Like, we’ve mentioned before how debris or heat can really mess things up.

Right, that’s where enclosures like TEFC come into play. That stands for "totally enclosed, fan cooled." It protects the motor from dirt, debris, even moisture, while improving efficiency and extending the motor’s life. It’s, honestly, kind of a no-brainer for heavy-duty environments.

And it keeps everything running smoother, longer. It’s funny how something as simple as a good enclosure can make all the difference.

Exactly. Without it, you’re, you're just inviting trouble—downtime, higher costs, you name it. And here's the thing—motors are the foundation of the whole system. Protecting them isn’t optional; it’s essential.

Efficiency and Reliability in Motor Design

So, speaking of how critical motors are, it’s interesting to look at how they’re evolving. For instance, induction motors have been such reliable workhorses for decades, but now we’re starting to see a shift toward permanent magnet motors. What’s driving that?Efficiency. Plain and simple. Permanent magnet motors are smaller, more efficient, and don’t have the slip you see in induction motors. That means less energy waste. And honestly, when energy costs are climbing, every bit counts.

Right, that makes sense. But that efficiency comes with a price tag, doesn’t it? These motors are more expensive upfront, though over time could be worth it with energy savings.

Definitely. Plus, they’re key if you’re working toward meeting these newer global efficiency standards. You’ve got NEMA for North America, IEC for Europe, and even GB standards over in Asia. It’s about staying competitive globally, especially with stricter regulations popping up everywhere.

It’s amazing how regulations like that can really push innovation. But, let me ask—how does all this play out in real-life scenarios? Like, when you’re out on a plant visit, what do you see?

Oh, I ran into an issue not too long ago. I’m at this plant, looking at their setup, and I notice this motor isn’t performing right. Turns out, it was mislabelled—like, the nameplate said one voltage, but it was wired for another.

Wait, seriously? That’s… scary.

Yeah. And the worst part? It could’ve wrecked the motor. Without catching that mistake, they’d be looking at downtime and a serious repair bill. It just goes to show how critical it is to know your equipment—down to the details on that tiny nameplate.

It really puts things into perspective. Efficiency doesn’t just mean better tech, it also means knowing how to use what you’ve got—and avoid costly mistakes.

Optimizing Compressor Systems

Speaking of knowing your equipment, that definitely extends to auxiliary motors. These might not always take center stage, but they play an essential role, particularly in cooling. A good cooling system is what keeps your main motors and equipment from overheating—and prevents costly downtime. Heat’s the enemy, especially for systems like air compressors, and without efficient cooling, you’re pretty much burning money.Right. And it’s not just one size fits all; different compressors use different setups. I’ve seen some systems with air cooling, where fans work hard to push heat out, and others with liquid cooling, which is a bit more complex but super effective when you’ve got a heavily loaded system.

Exactly. And here's where the auxiliary motors come in. For air-cooled units, you’ve got motors driving fans, pushing heat off through fin-and-tube setups. Liquid-cooled ones use smaller motors to assist fans and pumps, keeping the electronics and main motor from overheating. Simple, but critical to longevity and efficiency.

It’s funny how these smaller motors play such a big role. But that’s not where it stops—drive systems matter too, right? Like the difference between belt-drive and direct-drive setups?

Oh, yeah. Direct-drive motors are coupled straight into the airend, no belts or extra parts, so efficiency’s better and there’s less wear and tear. Belt-drive systems, on the other hand, use a belt-and-pulley setup. They’re reliable too, but they need a bit more maintenance over time. It’s all about what fits the application best.

That’s where variable-speed drives make a big impact, isn’t it? They’re a game-changer when it comes to energy efficiency.

Absolutely. VSDs let compressors adjust motor speed to match the air demand, saving energy. It’s that simple. But they’re not perfect for every situation—like, low-capacity operations below 20%, or high loads where you lose efficiencies in the drive itself. It’s all about balance.

And the best way to figure that out is with expert help. You know, I talked to a plant manager recently who worked with a local distributor to assess their compressor setup. They ended up installing a VSD unit configured by the distributor, and it cut their energy use by nearly 30%. That’s a huge win.

That’s solid proof of how much the right setup can save. And those distributors? They know these systems inside out. They’re a resource too many people overlook.

Exactly. They’re not just selling compressors—they’re partners who can help get the most out of a system. It’s about working smarter, not harder, and using the tech and people available to you.

On that note, that’s why staying informed is critical. It’s not always about upgrading—it’s about improving the efficiency of what you’ve already got. The knowledge, the details, and the right partnerships—that’s the real game-changer.

And that’s all for today. Great talking about this, Jason. Until next time, everyone!

Random stat or

customer quote

textXXtext

text