A Beginner’s Guide to Reading Rotary Screw Compressor Performance Curves

March 19, 2025

Three Reasons Rotary Screw Air Compressors Win the Total Cost of Ownership Derby. And 10 Ways to Drive It Even Lower!

April 2, 2025The Eight Key Components of a Rotary Screw Compressor

Kaishan USA | March 26, 2025| Uncategorized

There are eight key components of a rotary screw air compressor.

Identifying the functions of its different parts is a helpful step in operating a rotary screw air compressor efficiently.

Knowing what happens at each step and how the different components work together will enable you to get the quality and quantity of compressed air you need to meet the needs of your end-use applications.

The goal of this post is to present the most essential parts of your compressor and explain the role each plays in the compression process.

We’ll start at the beginning with the air inlet.

1. Air Inlet

The inlet valve is the gatekeeper for your compressor. It allows air into the compression chamber, opening fully during the load portion of the cycle and closing during the unload part.

The air inlet valve is one of the most important parts of a rotary screw air compressor.

As such, it is one of the most important and complicated parts of a rotary screw air compressor. No part of the compressor so uniquely differentiates the various manufacturers.

It regulates two significant functions:

- The air entering the compression cycle. If the volume of air entering the chamber is not sufficient, your compressor will struggle to provide enough air pressure. If the inlet valve brings too much air into the chamber, it could cause over-pressurization, damaging the compressor and nearby equipment. Underscoring the importance of this function, Kaishan’s KROF two-stage oil-free compressor even has hydraulic inlet valves to increase reliability in contaminated environments, with closed-system hydraulics ensuring positive sealing and controlling valve actuation through all operating pressures.

- The oil lubricating the airend. When your unit compresses air, we use air pressure as a fluid-motion device, creating oil pressure. Even when your compressor is in the unload state, you need to keep the oil flowing to the airend.

Kaishan is one of the few manufacturers who offer an adjustable inlet valve, available on our premium KRSP and KRSP2 rotary screw air compressors. The ability to adjust the inlet valve allows you to keep the oil pressure where you want it. Adjust it too high, and you’ll waste power. But if the pressure’s too low, you run the risk of locking up and causing significant damage to the airend. For more information on the air inlet valve, read our blog post, “What Is the Air Compressor Inlet Valve, and How Does It Work?”

Next is the control panel.

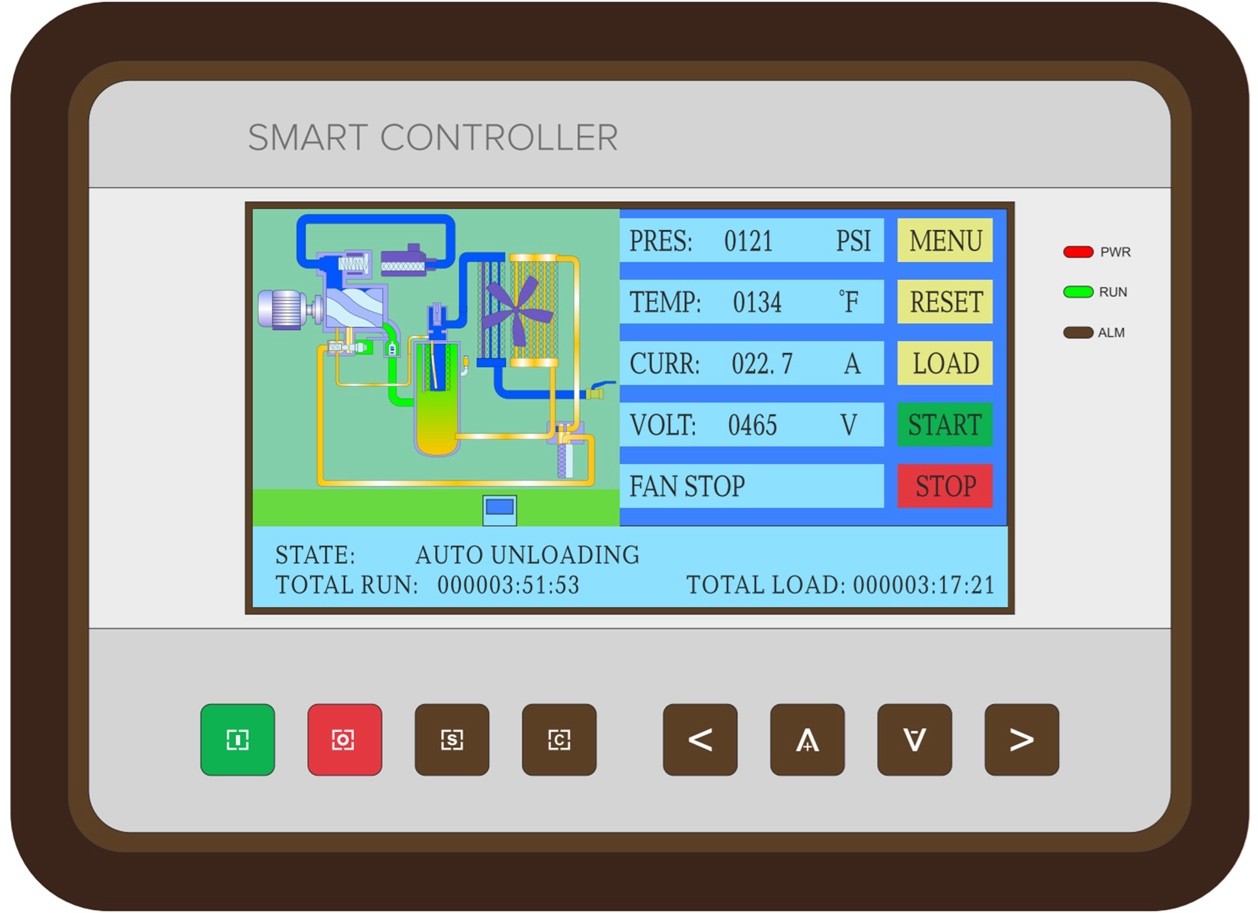

2. Control Panel

Today’s rotary screw air compressors feature a control panel, which displays all the information you need to know regarding the status of your compressor. It’s the user interface for the control system that regulates the operation of the compressor.

The control panel of a typical compressor can contain as many as five different voltages, so only a qualified electrician or compressor repair person should open the cabinet.

Every Kaishan compressor displays all relevant operational data on the screen of your compressor controls: pressure, temperature, voltage and any amps that are present. As a result, you don’t need to open the control panel to have the critical status information you need. More proof that we do everything we can to help you operate our equipment safely. For more on safety, see our blog post, “Four (and a Half) Critical Compressed Air Safety Tips.”

If you want to keep an eye on key parameters and receive notifications via text, you can even monitor your compressor remotely through the Internet of Things. We offer options like AirWatch, which digitally creates a twin online using Modbus protocol to display pressure, temperature, faults, status and other key indicators.

To make the process easier and safer, Kaishan units display all relevant data on the screen of your compressor controls: pressure, temperature, voltage and any amps that are present.

The controls adjust the operation of the motor.

3. Motors

Rotary screw air compressors have a main motor driving the rotors in the airend. Most have electric motors, but the driving function can also be fulfilled by a belt drive, as in our KRSB belt-drive rotary screw air compressors.

The motor's horsepower determines the compressor's capacity—the more horsepower, the greater its capacity. You need enough horsepower (HP) to generate all the energy needed to deliver compressed air at the required flow and pressure.

The main motor is not the only motor in your compressor—secondary motors may also drive cooling fans or oil pumps. Water-cooled machines also have very small motors for package flow, keeping the hot air circulating out of the package. Their coolers, however, do not need fans to move the package air out.

All our compressors are equipped with totally enclosed, fan-cooled motors, preventing debris and contaminants from entering the unit. The fan helps cool the unit, boosting efficiency and equipment life compared with open drip-proof motors.

A coupling connects the main motor to the airend (although some companies use a gearbox or other device between the motor and the airend to avoid use of couplings).

4. Airend

The airend is where a rotary screw air compressor does the main work of pressurizing the air. As the air enters a compression chamber, the two interlocking helical rotors or screws turn in opposite directions, reducing the space between the rotors and casing and compressing the air.

The rotors never touch and don’t wear, so they last a long time, creating long-term reliability that has become one of the hallmarks of rotary screw compressors. An electric motor typically drives the male rotor, which drives the female rotor.

Oil-lubricated rotary screw air compressors rely on oil to lubricate the bearings, seal off the air flow between the rotors and the stator and remove the heat of compression, keeping the compressor and the air flow cooler, reducing wear and tear and prolonging compressor life.

On the other hand, oil-free machines, like our KROF two-stage, oil-free, rotary screw air compressor do not inject oil in the airend. As such users can apply this technology in sensitive applications—such as food processing, semiconductor and electronics—without introducing oil to the pressurized air flow. More on this topic below.

The rotors of our KROF two-stage, oil-free, rotary screw air compressor are carefully machined to micron precision so that they can rotate without touching. And, unlike an oil-flooded unit, they have a coating that reduces corrosion and wear, prevents friction and seals them.

A compressor can also have several stages. A two-stage compressor like Kaishan’s KRSP2 premium rotary screw air compressor splits the workload, building on the pressure generated in the first stage. As a result, the KRSP2 generates up to 15 to 20% more flow than a single-stage compressor of the same size (HP). Payback on energy costs alone may be less than two to three years.

Kaishan’s KRSP2 two-stage rotary screw air compressor is one of the most energy-efficient machines on the market.

Kaishan’s KRSP2 and KRSP premium rotary screw air compressor are backed by a lifetime warranty on the airend.

As the pressure builds up in the airend, a variety of safety switches and pressure devices monitor pressure to ensure the air is at the correct pressure when it leaves the airend.

5. Sensors, Transmitters, Switches, Valves

Compressors use a variety of sensors, transmitters, pressure switches and valves to monitor and control key operational parameters, including pressures, temperatures and flow:

- A minimum pressure valve ensures that the pressure leaving the compressor meets the system requirements.

- Pressure switches track the differential pressure (or ΔP—a comparison of pressures before and after a device) to tell you if a filter is clogged. Most compressor manufacturers measure ΔP on oil filters. The critical inlet air filter mentioned above has a pressure switch to ensure it is not collapsed.

- Internal safety checks and valves measure temperature or pressure to ensure that your compressor is not over-pressurized, preventing injuries to your staff and damage to your equipment.

An oil-flooded screw compressor is monitored for temperature at two or three locations, while oil-free rotary screw compressors monitor additional values for temperature and pressure to protect the oil-free package.

6. Air-Oil Separator

After leaving the airend, compressed air is drawn into an air-oil separator to remove the oil mist the air injected into the air during the compression process in an oil-flooded rotary screw air compressor. The air-oil separator is a specialized device featuring a mesh filter element in a tank called a sump.

The air enters the separator tank or sump, which forces the air into a circular movement. The swirling action in the tank, combined with the filtration action of the separator element, removes oil mist from the air. The oil that falls to the bottom of the sump then goes back to the main oil tank to start the process over again.

All but a tiny fraction of the oil—3 parts per million—is removed. That’s clean enough for most industrial processes. But, as mentioned, it’s not good enough for sensitive applications, including:

The air-oil separator removes nearly all of the oil from the air compressed by a rotary screw machine. With advanced filtration, this air can support many sensitive applications, including some in food and beverage processing.

In those situations, you may be able to get the air quality you need with additional filtration to remove oil or other particles in the air. Or you may want to go with an oil-free rotary screw air compressor, such as Kaishan’s KROF two-stage, oil-free, rotary screw air compressor.

For more on deciding whether you need an oil-free compressor, see our blog post, “Ultimate Guide to Rotary Screw Air Compressor System Design, Part One: 10 Important Questions To Get You Started.”

And for more on air-oil separators, read our blog post, “Everything You Need to Know About Air/Oil Separators.”

Both the air and the oil leaving the air-oil separator need to be cooled.

7. Oil Cooler

Oil-flooded rotary screw air compressors have an oil lubrication system that seals the compression cycle, lubricates components and removes the heat of compression, lowering your system’s operating temperature. That heat is removed in the oil-cooling cycle.

Oil that is sufficiently cool goes back into the airend. Oil that is too hot goes through an oil cooler and is filtered to remove contaminants that could harm the compressor. It is then returned to the airend where the cycle starts again.

And while it’s true that oil-free units do not rely as much on oil, they still use oil to lubricate components and to lower the operating temperatures in the stage cooling jackets (keeping casting temperatures lower).

The compressor also needs to cool the air.

8. Air Cooler

Heat is also a factor for the air. The ambient air that entered your system at 70°F will reach about 175°F−200°F in an oil-lubricated screw compressor or approximately 350°F in an oil-free rotary screw or single-stage piston compressor, according to the Air Compressor Guide.

Air that hot will damage end-use tools and equipment, degrading lubricants and seal materials. It will also contain moisture that will cause corrosion and scale buildup. It may even result in freezing in colder climates, not to mention the quality problems water vapor-laden compressed air would cause in applications like automotive painting, semiconductor and healthcare and medical device manufacturing.

Cooling and drying equipment conditions the air to a more manageable level. To handle the additional heat from oil-free operation, our KROF has oversized stainless-steel precoolers on each stage, as well as intercoolers and aftercoolers.

The critical consideration for coolers is maintaining filters. Clogged filters will impede and eventually block airflow, causing energy loss that is both unnecessary and avoidable. So you’ll need to replace filter elements regularly.

Expert Help Is Close at Hand

If you need help mastering the components of your compressed air system and seeing how the parts fit together, we can help. Kaishan USA works with a nationwide network of independent distributors, who can provide on-site help and consultation as needed. These factory-trained air compression experts have the skills and expertise you need when you need it.

They can help you optimize the operation of your entire compressed air system with fast response times and personalized support tailored to your needs. Working with these compressed air professionals is the best way we can ensure you have the technical help, reliable service and quick access to parts you need.

They’re our partners and can be yours as well—a partner who cares about your business and wants to see it succeed.

Key Takeaways

The important components of a rotary screw air compressor include the following:

1. An air inlet, the gatekeeper allowing air into the compression chamber

2. A control panel, the interface for the control system

3. Motors, which drive the rotors in the airend

4. An airend, where two helical rotors compress the air

5. Sensors, transmitters, switches and valves, which monitor and control key parameters

6. An air-oil separator, where any oil mist is removed from the compressed air

7. An oil cooler, which eliminates the heat of compression from the oil

8. An air cooler, which helps lower the temperature of the compressed air

Let Us Help

Knowing the components of your rotary screw air compressor is an essential step in understanding how it works. And how it can work better. That, in turn, will benefit the operation of your compressed air system and all the processes that rely on that system. If you need help understanding how your compressor works, get in touch with the experts at Kaishan. Contact us today.

Listen to the Podcast Version

Essential Components: Air Inlet, Airend, and Efficient Compression

Welcome back to the Big Dog podcast brought to you by our friends in Loxley, Alabama! As always, we're glad you could join us.Alright, Lisa, let’s jump straight into the guts of it—the essential components of any rotary screw air compressor. Let's start with the air inlet, your gatekeeper. It’s like the bouncer of the whole operation. You need just the right amount of air coming in, or things start to wobble. Too little air, for example? Your compressor’s gonna struggle. Too much? You’re over-pressurizing, and that’s gonna wreck your system.

And that’s what makes it such a critical component. It’s not just about letting air in. It’s also managing oil flow, right? Because when air is compressed, the oil plays a dual role—it lubricates the system and helps manage heat. It’s fascinating how interconnected all these elements are.

Exactly. I mean, I’ve seen facilities wrestle with this. One shop I visited had their inlet valve set wrong for weeks—too much air coming in, and it ended up damaging some of their other equipment. The downtime alone was a nightmare.

Oh, I can imagine. And that’s where an adjustable air inlet becomes such a game changer. Brands like Kaishan even go a step further with hydraulic inlet valves for high-reliability needs. Especially in contaminated environments, you know?

Right. And while folks might think this is just a minor component, it really sets the stage for everything else to run smoothly. Now, once that air makes it into the compressor, we’ve gotta talk about what happens next—the airend. This is the heart of the machine.

The airend is where the magic happens, isn’t it? Once air flows in, the interlocking helical rotors compress it. And here’s the cool part: these rotors don’t actually touch. That’s what gives rotary screw compressors their longevity and reliability. No wear and tear on the rotors themselves.

And, yeah, the oil-lubricated ones are doing a ton of heavy lifting here. It’s not just about lubricating—like you said—it’s sealing off airflow and removing heat. That oil’s handling multiple jobs.

But not every application is going to be okay with oil mixing in, right? Take pharmaceuticals or food-grade applications. You don’t want any possibility of contamination. That’s where oil-free designs shine. Sure, they cost more up front, but for sensitive industries, they’re non-negotiable.

Oh, completely. It’s interesting how the extra stage in two-stage compressors, like Kaishan’s, doesn’t just split the workload—it boosts efficiency and even gives you energy savings down the line. That’s the kind of design thinking that minimizes operational headaches.

And it really underlines the importance of monitoring—air volume consistency and how those components work together. If the air inlet and airend aren’t perfectly in sync, you’re looking at inefficiencies, wasted energy, and potential system wear.

Yeah, and all of it comes back to the fundamentals—understanding these components and how they interact is key. Without that, you’re pretty much flying blind. And honestly, who can afford that?

Operational Control: Motors, Control Panels, and Monitoring Systems

Building on how those components work together, let’s talk about what drives them—the motors. Honestly, motors are one of those things you can’t afford to overlook. The horsepower is everything. It directly controls how much air you can compress. Bigger motor, higher capacity. But here’s the kicker—over-spec a motor, and you’re just burning through electricity you don’t need. Waste of power—and money.Exactly. And it’s not just about size. You’ve got primary and secondary motors, each doing their part. The secondary ones might be running cooling fans or oil pumps, and those are just as essential for the whole system to stay balanced. Plus, the design matters—a lot. The totally enclosed fan-cooled motors reduce the risk of debris getting in, right? Keeps everything running cleaner and longer.

For sure. Open motors? Forget it. They’ll let contaminants in, and then you’ve got a whole new problem on your hands. And when we’re talking about compressors used in extreme environments, like, say, manufacturing facilities that deal with a lot of dust or heat? That’s where these added protections pay off big time.

Right, and the motors need the control panel to make sense of all the moving parts. That’s the brains of the operation. From keeping an eye on pressure to temperature to voltage—it all shows up there. No more guessing games. And with IoT monitoring? Jason, the insights you get are next-level.

Yeah, I mean, now you can pull data through the Internet of Things about your system’s status wherever you are. I heard of a plant where the system flagged a pressure drop remotely—turns out, one of the valves was starting to go. They jumped on it before it even became a failure. That’s some next-gen troubleshooting right there.

Oh, absolutely. And it’s not just convenience. It’s safety. Look, these panels deal with multiple voltages. You don’t want someone just popping them open without knowing what they’re doing. It’s why the remote access tools are such a game changer—operators can monitor everything outside the cabinet and stay safe.

And speaking of safety, let’s talk about monitoring systems. We’re looking at sensors, transmitters, switches, valves—all keeping the whole system in check. I’m talking real-time tracking for things like pressure and temperature.

And if these systems aren’t calibrated regularly? That’s when things start to slip. A clogged filter here, a misaligned pressure reading there—it can spiral if you’re not proactive. Think about minimum pressure valves, for example. They make sure the pressure leaving the compressor fits the system requirements. But if they’re even slightly off, you could choke your whole operation.

Yeah, or worse, over-pressurize and put your folks at risk. The key is keeping those sensors sharp. Maintenance, Lisa. Maintenance saves lives... and machines.

Couldn’t agree more. It’s all interconnected—motors, the control panel, the monitoring systems. Overlook even one element, and you’re gambling with the entire performance. It’s about keeping every part in harmony.

And that’s where the risk lies—letting even a small issue snowball. Spot it, fix it early, and you save yourself a ton of headaches later on.

Thermal Management: Oil Cooler, Air Cooler, and Air-Oil Separation

And that’s exactly why everything we've talked about—motors, control panels, and sensors—ties into one crucial aspect: thermal management. If you let heat go unchecked, it’s not just a performance issue—you’re inviting a system-wide failure waiting to happen.Absolutely. So, let’s start with the air-oil separator. It’s a key player in ensuring air quality, especially for industries that can’t afford any contamination—like electronics or food processing. It removes nearly all the oil from the compressed air.

Right. And I’ve seen firsthand what happens when you let separators slack. There was this one facility I visited—had a separator that hadn’t been replaced in years. Long story short, a ton of oil got into their air system, ruined a batch of products, and they had to recall everything. Major hit to their bottom line... and reputation.

Oh, yikes. That’s a costly lesson. And it’s a reminder that preventive maintenance on these separators is non-negotiable. Keep the filters clear and change them on schedule to avoid those kinds of disasters.

Exactly. Plus, there’s the oil cooler to think about—it manages the heat generated from compression. Heat that doesn’t get handled? You’re looking at overheating issues, damaged components, and let’s not forget, way less efficient operation.

Right. It’s all about keeping that oil within a safe temperature range. If it overheats, it loses its ability to do its jobs—lubricating, sealing, cooling. It’s like a chain reaction. And honestly, best practices like keeping an eye on oil cleanliness and swapping it out at the right intervals make a big difference in stopping those problems before they start.

Yeah, but oil isn’t the only thing that needs cooling. The air cooler is just as critical. If you’ve got air running equipment downstream, and it’s overheating, you’re in big trouble. I mean, tools break down, seals fail. You’re setting yourself up for some serious downtime.

Absolutely. I’m thinking of a case where poor air cooling led to moisture problems in the system. The result? Corrosion and even ice forming in the lines during colder months. That’s why air coolers really need to be oversized sometimes—especially in, say, oil-free systems where the compressed air gets even hotter.

Honestly, this is why the whole system has to be balanced. Every component—from the air-oil separator to the coolers—needs to pull its weight. Otherwise, you’re just fighting fires instead of running a reliable operation.

And it goes back to monitoring, like we talked about earlier. If you’ve got systems tracking temperature and pressure at every stage, you can catch problems before they boil over—literally and figuratively.

Exactly. And that’s the key takeaway here: understanding these components and staying on top of maintenance doesn’t just save money—it prevents a ton of unnecessary stress. Know your system, keep it running efficiently, and you’ll thank yourself later.

Alright, and that about wraps it up for today. This was such an important conversation—so many critical elements that go into making these compressors work at peak performance.

Yeah, no kidding. And honestly, you take care of these fundamentals, and you’re already ahead of the game. So, keep that in mind, folks. Maintain those systems, and they’ll take care of you.

And on that note, thanks for joining us on The Big Dog Podcast. We’ll see you next time!

Random stat or

customer quote

textXXtext

text