What’s the Difference Between Full Load and Duty Cycle? And Why Should You Care?

July 2, 2025

Preserve Your Compressor’s Design Integrity by Using OEM Parts

July 16, 2025The Key to Air Compressor Longevity: Getting Your Bearings

Kaishan USA | July 9, 2025 | Uncategorized

Bearings make a significant contribution to the performance and service life of an air compressor.

Bearings are one of the most critical elements in an air compressor, but especially in the airend of a rotary screw compressor.

They perform the following essential functions:

- Reducing wear and tear, decreasing friction between moving parts

- Absorbing load and vibration, supporting the weight and the forces generated by your compressor

- Allowing smooth operation, keeping the parts in alignment and moving smoothly

- Ensuring an extended lifespan by doing all of the above

They achieve these results while the shafts are spinning at 3,000-6,000 revolutions per minute, with rotor tip speeds of 100-130 feet per second (30-40 meters per second). For oil-free compressors, the speed reaches 165-230 feet per second (50-70 meters per second), according to bearing manufacturer SKF.

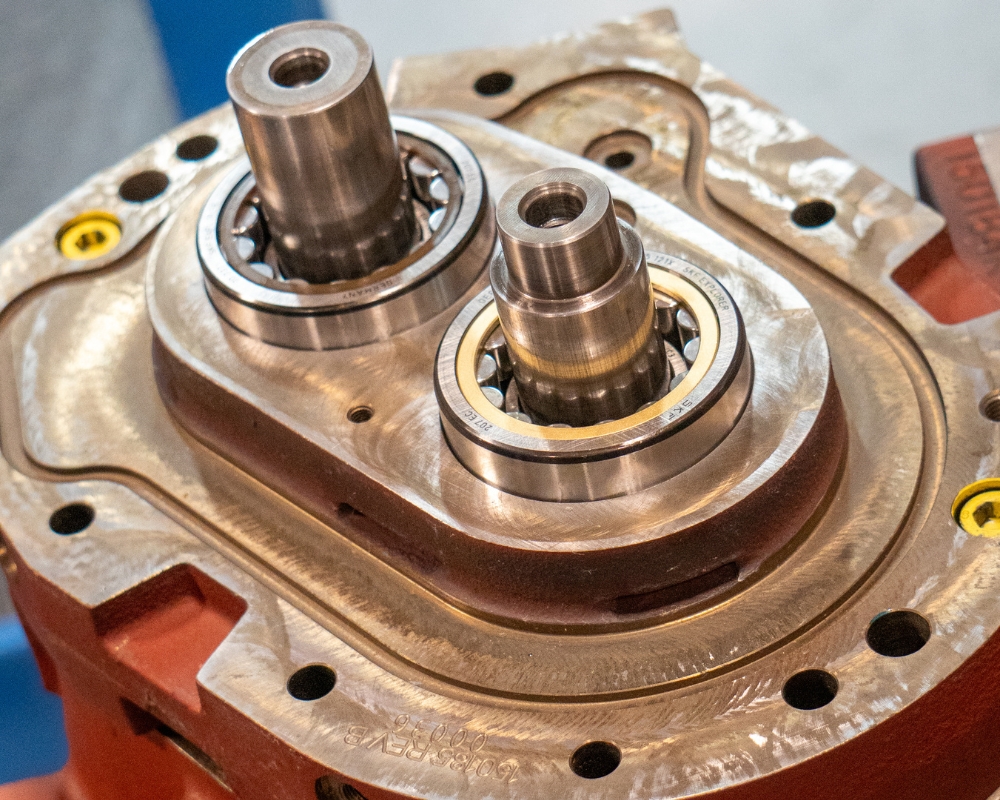

Compressor manufacturers use several different types of bearings, using them in both the main motor and the airend. Some, maintaining the alignment of the rotors in the airend. Others, in the compressor’s motors.

Types of Air Compressor Bearings

There are many different types of bearings used in air compressors, including the following:

- Ball bearings, which have rolling elements, balls and raceways, are used in high-speed applications where friction and loads are low. Ball bearings have single-point contact.

- Roller bearings, which have cylindrical rolling elements, rather than balls, can handle higher radial loads. The rolling elements can be tapered to provide additional load-bearing capacity and increased lifespan. Unlike the single-point contact of ball bearings, roller bearings have line contact, which distributes the load over more bearing surface.

Various types of bearings are used in air compressors, including ball, roller, thrust and journal bearings.

- Thrust bearings, which have rolling elements in a ring to handle low-thrust applications and primarily address axial load. They maintain shaft alignment and can use ball or roller bearings.

- Journal bearings, which use a film of lubricant, rather than rolling elements, to support the shaft that is rotating in a sleeve. They are deployed in high-speed and high-load applications.

Manufacturers of rotary screw compressors primarily use ball and roller bearings, whereas journal bearings are typically employed in reciprocating compressors to handle greater loads. Kaishan uses ball and roller bearings, and sometimes a combination of the two.

Bearing Quality

Kaishan uses premium SKF bearings in all its compressors, ensuring long life of the bearings and our compressors. It’s another example of our partnership with other U.S.-based suppliers to ensure all our components and parts are available with industry-leading lead times. No matter what you need, we have it in stock or nearby.

Bearing Life and Two-Stage Compressors

Longer bearing life is one of the advantages of a two-stage air compressor, such as our KRSP2 premium rotary screw air compressor.

Kaishan’s KRSP2 two-stage rotary screw air compressor is one of the most energy-efficient machines on the market, generating up to 15-20% more flow than a similarly sized single-stage compressor. And a payback in less than two to three years.

Two-stage compressors, such as the KRSP2, split the workload into two stages, resulting in less mechanical stress and lower heat, which reduces wear and tear and extends the life of air compressor bearings and other components. Because there are four discharge bearings on the first stage and three on the second stage, the bearings on the KRSP2 experience less stress than the two bearings that carry the entire thrust load in a single-stage unit.

As a result, two-stage compressors may be a solution for facilities experiencing frequent bearing failure. When equipped with a variable-speed drive, our KRSP2 is one of the only two-stage units available in sizes as low as 30 HP.

With lower forces and more air compressor bearings, the KRSP2 is built to last, enabling us to offer an industry-leading lifetime airend warranty.

Lifetime Airend Warranty

Kaishan KRSP2 rotary screw air compressors have the best warranties in the industry. Our standard warranty covers the complete compressor package for 12 months from the date of startup (or 18 months after it’s shipped, whichever comes first), with an airend warranty of 24 months. With our extended warranties (provided at no additional cost), Kaishan’s KRSP and KRSP2 screw compressors are backed by a lifetime warranty on the airend.

An unmatched lifetime airend warranty backs Kaishan’s KRSP and KRSP2 screw compressors.

Oil-Free Compressors

Because they don’t inject oil to cool and lubricate the airend, an oil-free compressor, such as Kaishan’s KROF oil-free rotary screw compressor, typically uses two stages to achieve the desired pressures. It runs faster and has special labyrinth seals to prevent bearing oil from entering the airend.

Bearing Maintenance

Key elements of bearing maintenance include controlling the environment and providing periodic lubrication.

First, you’ll want to avoid high levels of humidity, high temperatures and contaminants.

Second, because greasing intervals vary from machine to machine based on the motor size and type, make sure to follow your manufacturer’s recommendations for bearing lubrication. Kaishan uses the oil in the oil circuit to lubricate the bearings, sometimes adding an auxiliary oil pump (especially in oil-free variable-speed drive compressors and larger oil-flooded units). However, since the oil filter change interval is 2,000 hours, we encourage our customers to service all motors with a grease fitting on the drive and rear end at the same time.

It’s also wise to pay attention to excessive noise or vibration as part of your daily compressor operation. That may be an indication of bearing problems. Some companies even do vibration analysis as an additional preventive maintenance technique.

We encourage customers to monitor noise and vibration levels—often an early indication of a bearing problem—as part of their daily compressor operation. Some companies even do vibration analysis as an additional preventive maintenance technique.

The first indication of bearing trouble, however, often comes in an oil sampling report.

Oil Sampling

Fluid sampling can detect excessive bearing wear, allowing you to be proactive when you uncover a problem, even avoiding an unplanned shutdown. You should draw a fluid sample and have it analyzed every 2,000 hours (or twice a year, whichever comes first) to maintain warranty protection.

Most compressor manufacturers, including Kaishan, require oil sampling to maintain warranty eligibility.

If fine metal is detected in the sample, it indicates future bearing failure. Since the rotors never touch, you’ll only find metal in an oil sample if there is bearing failure.

Regular sampling will also indicate whether your compressor is exposed to excessive heat or is drawing in contaminants. Thus, it is critical to the life of an oil-flooded rotary screw air compressor, and most compressor manufacturers, including Kaishan, require it to maintain warranty eligibility.

Bearing in Mind: Local Help

Problems with air compressor bearings probably won’t fix themselves and will most likely lead to more extensive and expensive repairs. If you are experiencing issues with air compressor bearings, we’d strongly recommend that you work with your local compressed air professional to identify the cause.

That’s the kind of help you can get by working with our nationwide network of independent distributors. They can provide on-site assistance and consultation as needed.

We partner with these independent, local businesses because it's the best way to serve you. Unlike large corporate suppliers, there's no red tape; our distributors offer expert guidance, faster response times and personalized support tailored to your needs. They do much more than sell compressors—they build relationships, ensuring you get the right system, reliable service and quick access to parts when you need them most.

They have factory-trained technicians who have a deep understanding of industrial applications and can help maximize efficiency and minimize downtime. When you buy through Kaishan, you're getting more than a product—you're getting a local partner who cares about your business and wants to see it succeed.

Key Takeaways

- Bearings are one of the most critical elements in an air compressor.

- Various types of bearings are used in air compressors, including ball, roller, thrust and journal bearings.

- Kaishan uses premium SKF bearings in all its compressors, ensuring long life of the bearings and our compressors.

- Longer bearing life is one of the advantages of a two-stage air compressor.

- An unmatched lifetime airend warranty backs Kaishan’s KRSP and KRSP2 rotary screw air compressors.

- Key elements of bearing maintenance include controlling the environment and providing periodic lubrication.

- The presence of metal fines in an oil sample indicates a potential bearing failure. That’s why oil sampling is so critical to the life of your compressor.

Let Us Help

Problems with the bearings in your rotary screw air compressor can have a significant impact on the operation of your compressed air system and all the processes that rely on that system. If you need help identifying the root of bearing problems, get in touch with the experts at Kaishan. Contact us today.

Listen to the Podcast Version

The Backbone of Rotary Screw Compressors

What's up, everyone, welcome back to The Big Dog Podcast. I’m Jason Reed, and I’m here with Lisa Saunders. Today, we’re, uh, “bearing” down on a topic that doesn’t get enough love—bearings inside rotary screw compressors. Lisa, you ready to get into the guts of these machines?Always, Jason. Bearings are like the unsung heroes, right? I mean, they’re doing all the heavy lifting—reducing friction, absorbing loads, keeping everything spinning smoothly. And we’re talking about shafts running at, what, 3,000 to 6,000 RPMs? That’s wild.

Yeah, and don’t forget those tip speeds—up to 230 feet per second in oil-free compressors. That’s, like, faster than a fastball out of the major leagues. And if those bearings aren’t up to snuff, you’re looking at downtime, lost production, and a whole lotta headaches.

So let’s break down the types. You’ve got ball bearings—those are for high-speed, low-load spots. Then roller bearings, which handle higher radial loads. Thrust bearings, mostly for axial loads, and journal bearings, which are more for reciprocating compressors, right?

Exactly. In rotary screw compressors, like the ones Kaishan makes, it’s mostly ball and roller bearings. Sometimes a combo, depending on the design. And, uh, Kaishan uses premium SKF bearings across the board. That’s not just a name drop—SKF’s got a reputation for a reason.

I always wondered, Jason, does it really make a difference? Like, can you actually see the impact of switching to a better bearing?

Oh, for sure. I’ve got a story—there was this plant, running a bunch of compressors, and they kept having bearing failures. Like, every few months, same issue. They finally switched to premium SKF bearings—cost a bit more up front, but after that, failures basically stopped. They saved thousands, not just on parts, but on lost production. Sometimes you gotta spend a little to save a lot, you know?

That’s the kind of thing people don’t always see on the balance sheet, but it adds up. And it’s not just about the bearings themselves—it’s about the whole system running smoother, longer.

Surviving the Freeze

So, let’s talk about design. Two-stage compressors, like Kaishan’s KRSP2, split the workload between two stages. That means less stress and heat on each bearing, right?Yeah, exactly. Instead of two bearings taking all the thrust load, you’ve got four on the first stage and three on the second. That spreads out the stress, so each bearing lasts longer. Plus, you get 15 to 20 percent more airflow compared to a single-stage. It’s a win-win.

And that’s not just marketing talk. I mean, the numbers back it up. More airflow, less wear, and—this is big—Kaishan backs it with a lifetime airend warranty. Most places, you get a year or two, maybe, but a lifetime? That’s a statement.

Yeah, standard warranty’s 12 months on the whole package, 24 months on the airend, but with the KRSP and KRSP2, you get that lifetime coverage. It’s, uh, kind of a game changer for folks who want to run these things for the long haul.

And maintenance plays a huge role in making that warranty count. I talked to a maintenance team last month—they do oil sampling every 2,000 hours, like clockwork. Caught a failing bearing early, just from a little extra metal in the oil. Saved them from a total breakdown. Sometimes it’s the small habits that make the biggest difference.

Yeah, and that’s not just a Kaishan thing—most manufacturers want you to do oil sampling to keep your warranty. But it’s smart anyway. If you see metal fines in the oil, that’s your early warning. Ignore it, and you’re rolling the dice on a shutdown.

Proactive Maintenance and On-site Support

Let’s get into the nuts and bolts of keeping bearings happy. First off, control your environment—keep out humidity, heat, and contaminants. Then, periodic lubrication. Kaishan uses oil in the circuit, sometimes with an auxiliary pump for bigger or oil-free units. But you gotta follow the manufacturer’s schedule, or you’re asking for trouble.And don’t forget about distributor support. I mean, you can do everything right, but sometimes you need a pro on-site. Kaishan’s network of local distributors is a big deal—no red tape, just quick diagnostics and real help when you need it.

Yeah, I remember a plant where a critical line went down—bearing issue, of course. The local Kaishan distributor was there in, like, an hour. Had the right part, got them back up before the shift ended. That’s the kind of support you can’t put a price on.

And for oil-free compressors, it’s a whole other level. They run faster, use labyrinth seals to keep oil out of the airend, and if you get oil contamination, you’re in for a world of hurt. Kaishan’s design really focuses on keeping those bearings isolated and clean, which is huge for reliability.

Bottom line—bearings

Random stat or

customer quote

textXXtext

text