The Benefits of Installing Variable-Speed Drive Compressors

January 8, 2025

My Compressor is Rapid Cycling. Now what?

January 22, 2025The Role of Compressed Air in Robotics and Automation

Kaishan USA | January 15, 2025| Uncategorized

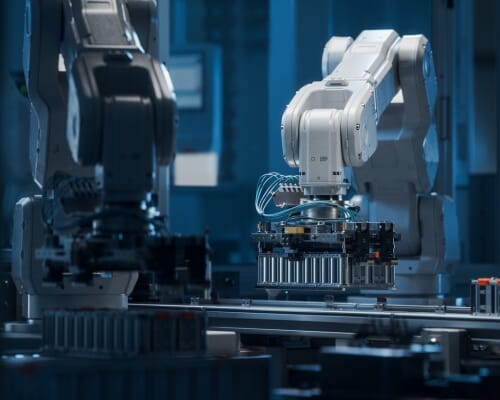

Semiconductor handling relies on robotics and automation powered by compressed-air-driven pneumatics.

Pneumatic devices have been in use for a long time. Centuries, at least. So, it may be surprising that designers of some of our most advanced devices, including robotics and automation equipment, are turning to pneumatics. Deploying pneumatic actuators throughout robotics and automation equipment.

But it’s only surprising if you don’t know the advantages that compressed-air-driven pneumatics offers to creators of advanced equipment. And their ultimate customers, the end users of that equipment.

From pick-and-place machines to robotic arms used in automotive manufacturing to semiconductor handling devices, pneumatic actuators provide the power that is changing how we make products. Other applications include:

- Pneumatic grippers in packaging and assembly processes

- Linear actuators that operate valves or power assembly lines

- Pneumatic brakes

It’s a technology that offers benefits for both machine designers and equipment end users. Let’s start with equipment designers.

Why Machine Designers Like Pneumatics

Machine designers would be hard-pressed to find a power source that matches the performance of pneumatic systems:

- Strong. Pneumatic devices are stronger than comparable electric devices, delivering higher torque levels.

- Lightweight. Pneumatic systems do not require a motor or battery, so they are remarkably lightweight. That saves crucial fractions of ounces and allows designers to create ever-lighter robotic arms and assemblies.

- Small. Similarly, pneumatic devices are compact and take up less space, critical in today’s tight designs.

- Fast. Pneumatic actuators are faster than electric devices of a similar size, delivering more revolutions per minute (RPM). They react almost instantaneously, making them ideal for high-speed automation systems.

- Flexible. Because of their strength, speed and small size, pneumatic systems give designers of robotics and automation equipment a lot more flexibility and maneuverability.

- Precise. When equipped with electronic controls, pneumatic devices have positioning accuracy comparable to electromechanical and hydraulic systems.

- Versatile. You can design compressed air-driven tools to drive linear or rotary motion. They are dynamic enough to do almost anything you need. We rarely see a specification that a pneumatically controlled device can’t meet.

- Sensitive. Compressed air has a “cushioning effect,” according to the National Fluid Power Association, giving pneumatic devices a softer touch than is possible with hydraulics or electromechanical devices. Many designers value pneumatic systems for their pressing and squeezing ability, which can be critical in handling items that are fragile. And see how pneumatics can make moving a 10-ton compressor look like child’s play.

Compressed air has a cushioning effect that gives pneumatics a soft touch critical for automated handling of sensitive items.

Because of those unique advantages, you can expect designers of robotics and automation equipment to continue assigning pneumatics a critical role in developing even more advanced equipment. Such as human-collaboration “cobots,” currently mostly driven by electrical motors and drives, according to a recent article in Tech Briefs.

End-users, on the other hand, like the performance advantages of pneumatically driven equipment.

Why End Users Like Pneumatics

Pneumatic systems offer many advantages in end-use applications. And that all adds up to a lower cost of ownership:

- Safety. Compressed-air-driven pneumatics offers machine designers a wide range of advantages over other types of power. Pneumatic systems don’t rely on batteries and people aren’t electrocuted by compressed air. Compressed air doesn’t explode on the factory floor. And when it leaks, compressed air comes out as, well, air. No puddles on the floor. No slips and falls. In addition, pneumatically controlled braking systems can stop a piece of equipment, such as a train car, in the event of a power failure.

Pneumatically controlled braking systems, such as those on a train, can even bring equipment to a stop in the event of a power failure.

- Resistance to harsh environments. Pneumatic systems can withstand hostile environments, such as mining, where the use of robots reduces hazards to human workers. Pneumatic devicess perform better than other power sources, resisting heat, dust and dirt. Even corrosive chemicals, high radiation or underwater applications. And can handle temperatures from below zero to 200°F.

Pneumatic systems are better than other power sources in harsh environments or dangerous settings.

- Reliability. Air-powered tools such as sanders, grinders, spray guns and sandblasters hold up much better under constant use than electrical equipment and are not easily damaged. Generally, pneumatic systems have a longer service life than comparable electrical or hydraulic systems.

- Low maintenance. Because of their relatively simple design, pneumatic devices experience less overheating, less wear and fewer breakdowns. Maintenance intervals are shorter as well.

- Less downtime. With reduced maintenance requirements and fewer breakdowns, you will have less costly downtime.

- Cleanliness. You can purify compressed air to your heart’s content. With the right compressed air systems, you can even achieve purity that meets strict ISO 8573-1 (2010) Class 0 standards. Since the final output is air, compressed air systems do not cause pollution or contamination in the workplace, making them ideal for locations, like semiconductor fabrication, robotic surgery or food processing, where cleanliness is critical. At least in output, they are environmentally friendly.

Because of their inherent cleanliness, pneumatic systems power the robots used in surgery.

- Low initial cost. Pneumatic systems have a lower initial cost than comparable hydraulic and electrical motors and drive systems.

Low Cost of Ownership

Without even factoring in the performance advantages pneumatics offers, the combination of safety, reduced maintenance, less downtime and lower initial cost translates into a lower cost of ownership.

The Key to Pneumatics Is Compressed Air

Your success in deploying pneumatic systems depends on having a consistent source of compressed air. A compressed air professional can help you design, install and maintain a system that will supply the pressure and flow you need.

Kaishan USA works with a nationwide network of independent distributors, who can provide on-site help and consultation in creating a system that will meet your needs. These factory-trained air compression experts can also install and service your air compressor system without a problem.

Key Takeaways

Machine designers like pneumatic systems because they are:

- Lightweight

- Small

- Fast

- Flexible

- Precise

- Versatile

- Sensitive

End users like pneumatic systems for their:

- Safety

- Resistance to harsh environments

- Reliability

- Low maintenance

- Minimal downtime

- Cleanliness

- Low cost

- Low cost of ownership

Let Us Help

Taking full advantage of the power of pneumatic systems is crucial for most companies. If you need help, get in touch with the experts at Kaishan. Contact us today.

Listen to the Podcast Version

Advantages of Pneumatics in Robotics and Automation

Hey, everyone! Welcome back to the Big Dog podcast! We're grateful to spend a few minutes with you.Alright, Jason, so, I have to ask. Pneumatics in robotics. It's kinda wild, right, how this old-school tech is driving some seriously cutting-edge stuff?

Not really. I mean, when you look at the advantages, it’s clear why. It’s lightweight, it's powerful. And costs? Way less than a lot of other systems.

Exactly. And like, in automotive manufacturing? Those robotic arms rely on pneumatics because they’re so quick to respond. We’re talking immediate power delivery. There's zero lag.

Right. And designers love that speed. Plus, those pneumatic actuators on pick-and-place machines? Precise. When paired with electronic controls, it’s as good as any high-end electromechanical system out there.

Oh, for sure. And it’s not just precision—it’s the flexibility. Designers can create all kinds of innovative robots because these systems are, well, versatile. You’ve got linear motion, rotary, whatever's needed.

And don’t forget strength. Pneumatic devices pack more torque than electric ones of the same size. That power-to-weight ratio gives them a real edge, especially when space is tight.

Absolutely. Like in semiconductor handling? Those machines are so compact, but pneumatics keeps the whole thing efficient. It’s incredible how much you can do in such a small footprint.

And it's fast too. High-speed automation runs smoother when you're dealing with pneumatic systems. Electric actuators just can't keep up in certain use cases. And that flexibility to adapt? Huge for innovation.

It really makes sense why pneumatics are still a go-to for designers, even with all the advancements in other tech. It’s not just about being cost-effective—it’s like, efficiency on every level.

Efficiency, flexibility, and power. That’s really the trifecta here...

Safety and Reliability of Pneumatic Systems

So with all that efficiency and flexibility, there’s another critical aspect we need to touch on—safety. Pneumatics are hands down one of the safest systems out there, especially compared to electrical or hydraulic setups. No electrical shocks. No explosions. It’s just air, right?Right! And even when something leaks, it’s, like, air coming out. No mess, no hazard, no... catastrophic failure.

Exactly. And that air cushion effect? It’s why these systems are ideal for sensitive operations like medical robotics or semiconductor handling. You’re not crushing fragile stuff under a ton of force.

Oh, like robotic surgery machines. I read somewhere that pneumatics give surgeons that soft, precise control they need. It’s so precise it’s, well, sort of reassuring in these high-stakes settings.

And durability is another big one. Pneumatic tools and systems outlast most electrical setups, especially in nonstop industrial use. Less wear means fewer breakdowns.

And less downtime. That’s, like, gold for manufacturers running on tight schedules. For example, I heard about this one plant—

Yeah, I think I know the one you're talking about.

So, they swapped out a failing electric system for a compact pneumatic setup. Suddenly, maintenance calls plummeted, production ramped up, and they cut costs on repairs. It just solved everything.

Makes sense. Pneumatics are simpler, fewer moving parts. Less heat, less wear and tear. It’s almost engineered for constant use in harsh conditions.

Totally. And with fewer issues, the system practically pays for itself in saved downtime and maintenance costs.

And reliability like that is why pneumatics keeps showing up in industries that can’t afford to stop. It’s the backbone, plain and simple...

Performance of Pneumatic Systems in Challenging Environments

And speaking of reliability, isn’t it wild how pneumatics excel in the harshest of conditions? One minute they’re handling cleanrooms, and the next they’re thriving in gritty mining operations—it’s amazing.Yeah, it’s the versatility. High heat, cold, dust, underwater—you name it. Pneumatic systems don’t blink. And less moving parts means less to fail in extreme conditions.

Totally. And in places like food processing or semiconductor fabrication? You’ve got these insanely high cleanliness standards, right? Compressed air systems can hit that mark because the output can be pure air. No contamination worries.

Exactly. But here's where it gets critical—the air has to be filtered. Otherwise, you're risking particles clogging things up. That’s where the maintenance systems come into play—keeping it efficient and sustainable.

Oh, and then there’s automation. Didn’t that robotics manufacturer, uh, what was it, in a mining setup, prove how adaptable pneumatic systems are? They used it to overcome all those particles and debris flying around.

Right, they designed this pneumatic-powered robotic arm assembly—it worked faster and handled the environment better than anything electric they’d tried before. No overheating, no failures, even in all that dust.

And the best part? Their system ran for way longer between maintenance shutdowns. Huge cost saver, especially when downtime means lost production.

Exactly. Pneumatics succeed where other systems struggle. It’s all about how they’re built for durability and efficiency, not just performance. That combination is a game-changer in these industries.

Honestly, it feels like there’s no end to what pneumatics can handle. From delicate surgical robots to, like, industrial beast mode. It’s flexible enough to work anywhere.

And that’s why they’re still the top choice for challenges that require power, precision, and reliability. It’s not just old tech—it’s smart tech.

Smart tech, yeah. Well, that wraps up our look at pneumatics transforming robotics and automation. Thanks for tuning in, everyone. Keep innovating out there!

And we’ll catch you next time on The Big Dog Podcast.

Random stat or

customer quote

textXXtext

text