Industrial Compressors for Automotive Shops

June 28, 2023

Which Type of Air Compressor is Best for Your Application?

July 12, 2023Four Compelling Applications of Vacuum Technology

Kaishan USA | July 5, 2023 | Uncategorized

You’ll find vacuum-forming technology in all kinds of manufacturing applications—including the production of a box of chocolates.

Advanced vacuum technology has revolutionized several important applications and industries, reducing cost, streamlining operations, improving precision, and boosting product quality.

Four processes are employed, including vacuum forming, packaging, holding, and mailing. Let’s review each one.

Vacuum Forming

Industries from automotive and agricultural products to food processing and medical devices use vacuum forming to create a wide range of products. You’ll find vacuum-formed parts of all shapes and sizes in the following applications:

Many automobile manufacturers use vacuum-forming technology to make dashboards and door panels.

-

-

- Automobile bumpers, floor mats, dashboards and door panels

- Truck beds and parts for other modes of transportation like vans, buses, boats and airplanes

- Agricultural equipment and heavy machinery

-

Vacuum-formed pieces even find their way into agricultural equipment and heavy machinery.

-

-

- Household items like bathtubs, utensils, appliances, skylights and garden equipment

- Acrylic signs and pop-up displays

- Merchandising like point-of-purchase displays and end-cap fixtures

-

Vacuum-forming technology helps manufacturers make household items like bathtubs.

Vacuum forming, the simplest type of plastic thermoforming, involves heating a sheet of plastic until it becomes pliable, then placing it in a mold, which can be either a convex or concave shape.

The mold may have tiny holes to allow the vacuum to remove the air between the plastic and the mold. The vacuum pulls the plastic into the mold, distributing pressure evenly across the sheet.

After the plastic cools, it can be pulled from the mold. The edges of the finished plastic piece can be cut to remove excess material, and the edges sanded or smoothed.

Vacuum forming is designed for parts or pieces that must be precisely formed only on one side. It is more affordable than other methods like plastic injection molding because tooling is less expensive and can be made in half the time.

Molds, for instance, can be made of wood, aluminum or structural foam. And some companies are speeding the process along even further by using 3D printers to create molds. Plus, plastics like acrylic, polyethylene and polycarbonate are inexpensive. As a result, vacuum forming cuts the time and cost of doing rapid prototypes or testing new design options.

Vacuum technology allows precise control and monitoring and provides consistent, repeatable results, including some intricate designs. You can vacuum-form a wide range of materials, including thermoplastics, composites and foams. Color options are available, as are fire-retardant and UV-resistant materials.

Vacuum Packaging

Vacuum technology plays a dual role in packaging, both in creating packaging materials and in assembling the final package.

Packaging Materials

Vacuum technology, as mentioned above, is used in vacuum-forming to create a variety of different types of packaging materials:

Pharmaceutical pill packaging is made using vacuum-forming technology.

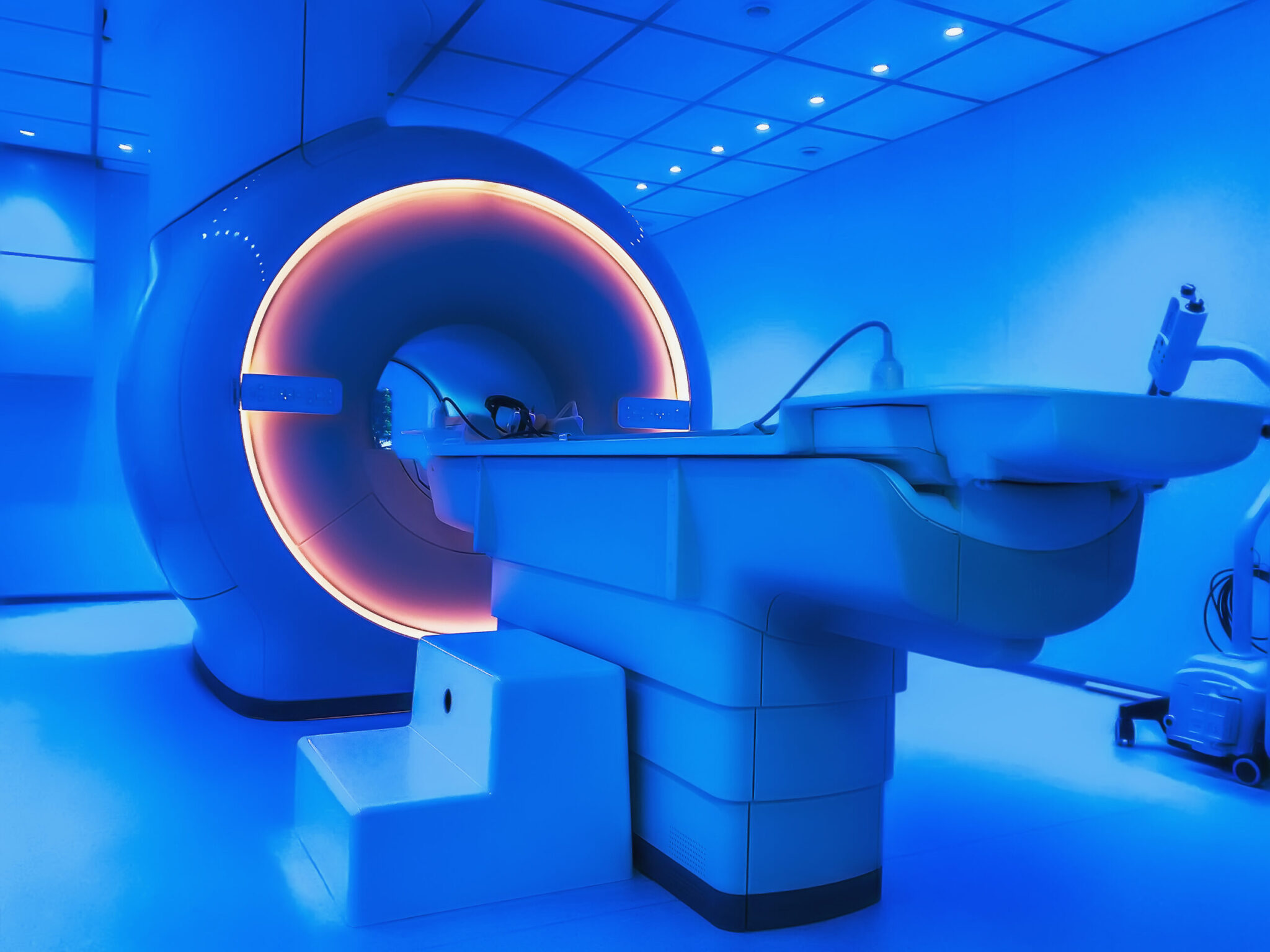

- Medical packaging pharmaceutical pill trays, dental retainers and some components of hospital beds and MRI and CT machines

Medical device manufacturers use vacuum-forming technology to make parts of magnetic resonance imaging (MRI) machines.

-

-

- Food-grade containers holding fruit, eggs, crackers and chocolate candies

- Aviation and automobile parts, packaged to prevent damage to delicate parts components, also minimizing oxidation (and subsequent rust and corrosion)

- Packaging for razors, toothbrushes, electronics, makeup and cleaning products

- Industrial crates and contoured containers for machinery

-

The Packaging Assembly Process

In addition, vacuum technology is used in the process of assembling the final package, mainly to remove air from the final package to protect against spoilage, moisture and contamination. These industrial packaging assembly applications include:

-

-

- Medical devices, like disposable equipment, are packaged in a clean-room environment to ensure sanitary, bacteria-free delivery.

- Pharmaceutical packaging uses vacuum technology to ensure long shelf life and deliver a hygienic, tamper-evident product, free of moisture, dirt, mold and germs.

- Food and beverage products rely on attractive, hygienic vacuum packaging (see our recent blog post, “Four Applications of Industrial Vacuum Pumps in Food and Beverage,” to preserve freshness, extend shelf life, prevent contamination and even, in the sous vide (literally, “under vacuum”) concept, to ensure food retains its natural flavor and texture.

-

Vacuum technology removes air from food packaging to prevent spoilage and contamination.

Vacuum Holding

Vacuum technology is used in various industries to hold products in place while they are being machined, cut or processed. Examples of workpiece holding or fixation include:

Vacuum-powered suction cups play a vital material handling role in glass manufacturing.

-

-

- Vacuum-powered suction cups help industries handle metal and sheet metal, even when the surfaces are oily or hot.

- Glass and stone cutters use vacuum lifters that can be tilted manually or with hydraulics.

-

Using a vacuum to hold a workpiece in place distributes pressure evenly across the entire surface, reducing the possibility of slippage or movement while the piece is being processed. It’s usually faster than mechanical clamps or adhesives.

Plus, vacuum fixation lessens the chance of surface damage. It won’t leave marks or indentations that sometimes occur with clamps. That’s especially important in the furniture and automotive industries.

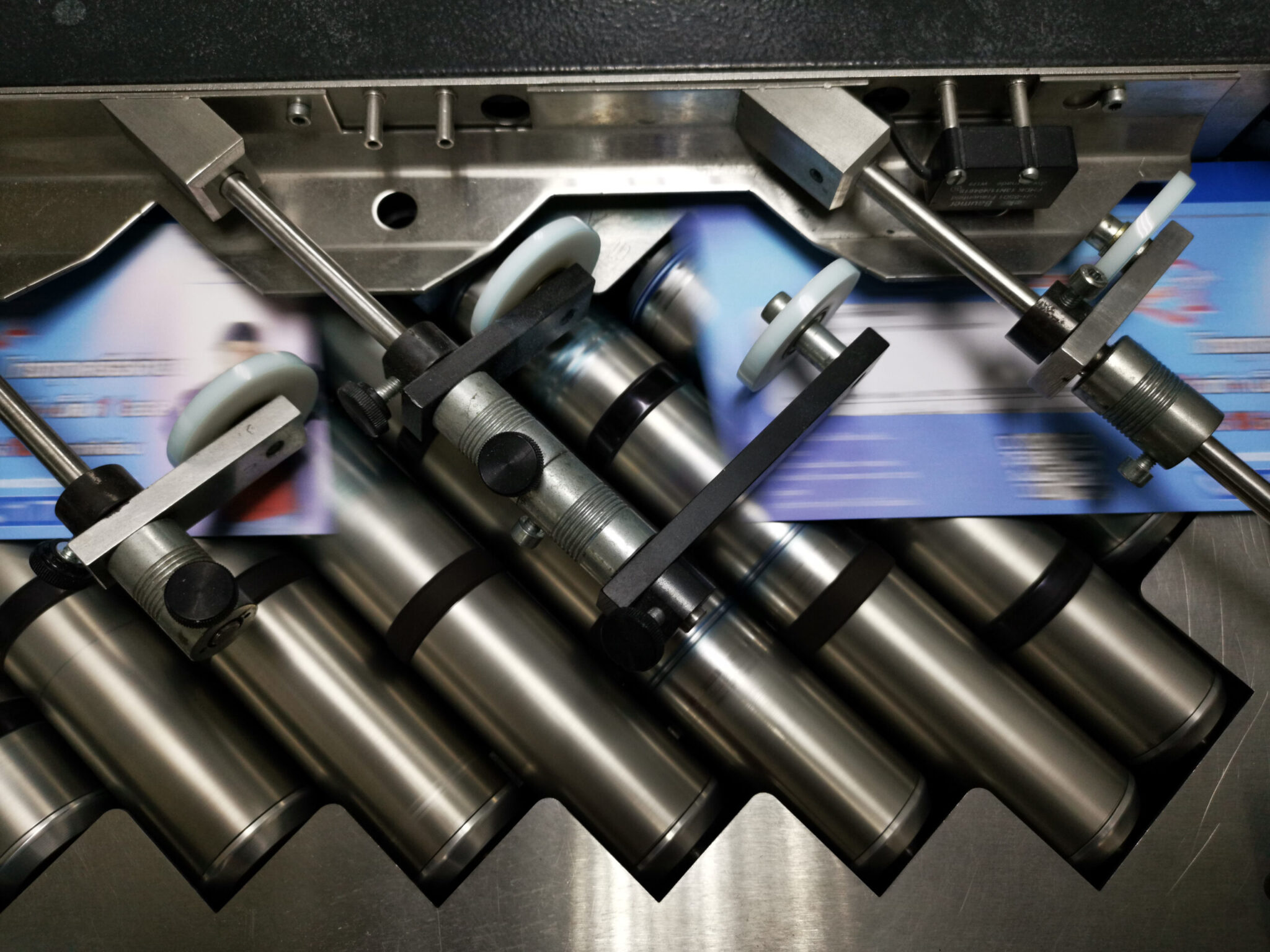

Vacuum technology drives the new envelope-cutting and filling machines that have made traditional mailing operations more efficient.

Vacuum-Assisted Mailing

Vacuum technology has revolutionized traditional mailing and envelope-stuffing, transforming a time-consuming and tedious process. And, in the process, streamlining operations, improving productivity and reducing cost.

Automated devices use vacuum-created suction to pick up items one at a time and insert them into envelopes quickly and efficiently. Avoiding the errors that occur with manual operations.

Vacuum folders can process even glossy and coated stock, giving mailings a professional, finished look. More advanced models have vacuum control and variable speed drives, allowing you to use not only different paper sizes and stocks, but also different media like envelopes, bags, calendars and even jewel cases.

Rotary Screw Vacuum Pumps

Rotary screw vacuum pumps like Kaishan’s KRSV are widely used because of their reliability, efficiency and ease of maintenance. The KRSV is the industry’s only vacuum pump with a variable discharge port.

While there are several different types of vacuum pumps on the market, most companies find that rotary screw vacuum pumps like Kaishan’s KRSV are the best choice for their application. Rotary screw vacuum pumps offer several critical advantages:

-

-

- Reliability. Rotary screw vacuum pumps are more reliable, last longer and are easier to maintain.

- Low energy consumption. Pumps equipped with variable speed drives and variable discharge ports like Kaishan’s KRSV optimize the energy required to perform at various vacuum levels, thereby increasing overall efficiency. Kaishan is the industry’s only vacuum pump manufacturer offering a variable discharge port.

- Low maintenance. Rotary screw vacuum pumps reduce the total cost of ownership through reduced maintenance costs.

- Low noise. Many rotary screw vacuum pumps are quiet enough to hold a conversation nearby.

-

A Centralized System

As vacuum technologies have become more widespread, companies have found themselves having multiple individual vacuum pumps, many built into processing equipment by the manufacturer. Unfortunately, that evolution comes at a high cost in efficiency and reliability.

We recommend transitioning to a single, centralized vacuum capability to improve energy usage, reduce maintenance costs, cut noise levels and improve the reliability of your vacuum capabilities.

Local Help

Selecting the right vacuum pump to service a variety of applications can be challenging. That’s why Kaishan USA works with a nationwide network of independent distributors, who can provide on-site help and consultation as needed. These factory-trained air compression experts have an investment in their local communities and can service your air compressor system without a problem. And they have staff members who are skilled in using leak-detection technology on a daily basis.

Key Takeaways

-

- Technological advances. Vacuum technology has revolutionized several important applications and industries, reducing cost, streamlining operations, improving precision and enhancing product quality.

- Vacuum forming. Industries from automotive and agricultural products to food processing and medical devices use vacuum forming to create a wide range of products.

- Vacuum packaging. Vacuum technology plays a dual role in packaging, both in creating packaging materials and in assembling the final package.

- Vacuum holding. Vacuum technology is used in a variety of industries to hold products in place while they are being machined, cut or processed.

- Vacuum-assisted mailing. Vacuum technology has revolutionized traditional mailing and envelope-stuffing, transforming a time-consuming and tedious process.

- Rotary screw vacuum pumps. Rotary screw vacuum pumps like Kaishan’s KRSV are widely used because of their reliability, efficiency and ease of maintenance.

- Centralized systems. Rather than have vacuum pumps servicing a wide variety of individual processes, we recommend a single, centralized vacuum capability to improve energy usage, reduce maintenance costs, cut noise levels and improve reliability.

Let Us Help

Vacuum technology plays a significant role in industry today. If you need help finding the right vacuum pump for your application, get in touch with the experts at Kaishan. Contact us today.

Random stat or

customer quote

textXXtext

text

Advanced vacuum technology has revolutionized several important applications and industries, reducing cost, streamlining operations,