How You Can Turn Your Compressed Air System into a High-Efficiency Profit Center

July 30, 2025

How Often Should an Air Compressor Cycle?

August 13, 2025What Happens When the Pressure Is Too Low for Your Air Tools?

Kaishan USA | August 6, 2025 | Uncategorized

To operate effectively, impact wrenches must receive compressed air at the pressure specified by their manufacturer.

If your compressed air system is not delivering the 90-PSIG or 100-PSIG your impact wrench requires, it will operate more slowly. It may not have enough torque to tighten or loosen bolts as required. If it’s tightening the lug nuts on a wheel, they could loosen and allow it to come off, potentially resulting in damage or injury. All because the tool was not receiving the required air pressure.

The same is true of almost all air tools. And, unfortunately, the go-to solution for all-too-many maintenance workers—increasing the pressure output of their rotary screw compressor—is often a bad idea.

Here’s why. Because of the inverse relationship between pressure (PSIG) and flow (CFM), trying to increase the pressure at a remote end-use by boosting the pressure your compressor outputs probably will produce less air at the targeted application. And, most of the time, when a user says he’s not getting enough pressure to run his impact wrench, it’s a problem of flow, not pressure.

In addition, compressed air suffers from the Goldilocks syndrome: “too much” is just as bad as “not enough.” So the primary challenge in managing a compressed air system is getting it “just right.” And keeping it there.

You want to avoid both extremes:

- Pressure too high. Pressure that is too high can damage your equipment. And a previous blog (“How Lowering the Pressure Band of Your Compressed Air System Can Save You Money”), describes the loss and inefficiency that occur when the pressure in your system is too high.

- Pressure too low. On the other hand, pressure that is too low may not deliver the speed and torque your end uses require.

We have covered the compressor side of the low-pressure problem, discussing “What To Do When Your Air Compressor Is Not Building Pressure.”

This post goes into more detail on the importance of avoiding low pressure, explaining what happens at the end of the line. To the applications, tools and work products that aren’t getting the pressure they need.

We’ll start with the impact on the tools themselves.

What Happens to Air Tools When Pressure Is Low

When the compressed air your system delivers does not reach the level recommended by the tool manufacturer, an air tool will not work correctly. The following problems will arise:

- Lower speed. The tool will run slower, not at the recommended RPMs.

- Less power. The tool may not be able to deliver the required torque.

- Lost or damaged products. Depending on your product and process, an under-powered air tool may not be capable of performing its task in the allotted time (if at all). Product loss or damage may result.

- Higher costs. The device will take longer to complete its task and waste energy in the process. You may need to scrap lost or damaged products.

- Lower productivity. As a result of the previous points, productivity will be lower.

- Damage to the tool itself. Although most tool damage occurs when the equipment is over-pressurized, there may be more long-term wear and tear, resulting in a shorter lifespan.

- Safety hazards. Anytime a tool is operated outside its design parameters, safety is compromised.

Low-Pressure Problems: An Example

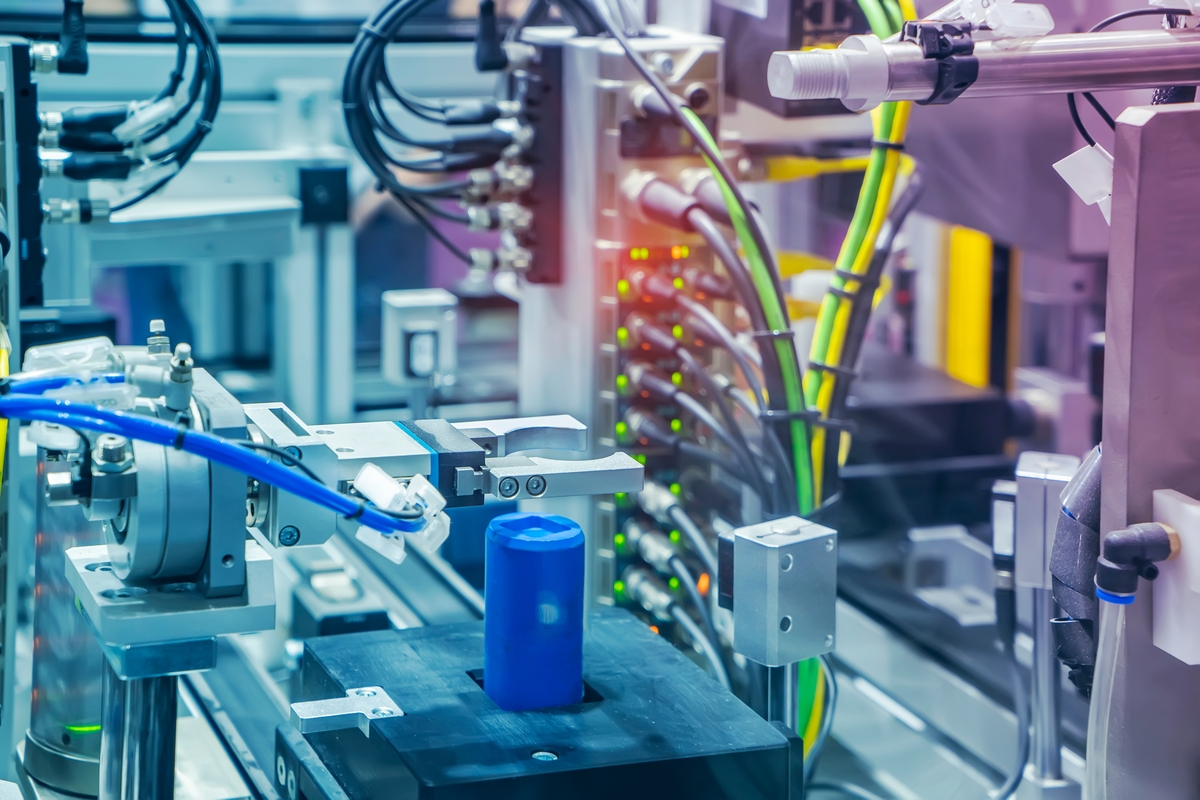

In one past example, a plant suffered a power failure. And while the electricity was off for the entire plant, a computer numerical control machine powered by compressed air continued to operate, using compressed air stored in receiver tanks. That’s the good news.

The bad news was that the machine’s clamps gradually lost power as the air pressure dwindled. As a result, the workpieces weren’t held as tightly and began to move and shift slightly, not a good thing for precision machining. As a result, all the workpieces had to be scrapped.

Nowadays, CNC manufacturers typically install pressure regulators on their machines to keep pressure within design parameters.

It’s essential that computer numerical control machines receive compressed air at the exact pressure specified by their manufacturer.

Why is an Air Tool Performing Poorly?

The main reason a device is underperforming, of course, is that it’s not getting enough air pressure. For some reason.

But you make a serious mistake if you immediately increase the pressure the compressor is providing.

Here’s why: First, as mentioned, because of the inverse relationship between flow and pressure, increasing the compressor’s output pressure decreases the flow. And there are other reasons why an end-use is not performing well:

- It may need lubrication.

- It may be wearing out.

- There may be a leak in the connecting hose, piping or fitting.

As a result, you’ll want to follow a logical process to determine the cause of the problem.

What to Do About Low Pressure

Rather than immediately raising the pressure at your compressor, you’ll want to eliminate other possible causes. If you’re finding your air tools are underperforming, follow this process:

- Check the compressed air pressure at the tool. If pressure is adequate, your problem is with the tool itself.

- Examine the air delivery system, including the hose size, piping and fittings. Are they working properly? And are they sized correctly? You’ll want to pay special attention to the notorious “dirty 30”—the pipes, tubing and hoses providing the tool with air. For a variety of reasons, pressure can drop as much as 30 PSIG-50 PSIG in that last 30 feet, according to Compressed Air Best Practices.

- Look for leaks or other pressure drops.

Only then should you increase the pressure provided by your compressor. Remember, however, that increasing pressure for the entire system can significantly raise your electricity costs. As mentioned, we discuss this topic more fully in our post, “What To Do When Your Air Compressor Is Not Building Pressure.”

Depending on the pressure requirements of each machine, you can use a pressure regulator as close to the tool as possible to maintain the correct pressure. A regulator also helps make the tool last longer.

A regulator located as close as possible to an air tool can ensure it gets the required pressure.

Where to Get the Lowdown on Pressure Concerns

If low pressure is a recurring issue for your compressed air system, an audit by a compressed air professional will help you determine the best way forward.

For low-pressure issues, an audit can help you determine how large your system needs to be. Too many companies size their compressors assuming the worst-case scenario—that all their machines are running continuously. An audit will list all the tools on the demand side, assess their utilization and determine the right mix of compressors and storage that will meet your needs.

An audit also will help you identify and deal with issues such as proper sizing, rapid cycling, energy conservation, poor performance, leaks, low air quality, shortened lifespans and more.

In one outstanding example, Iowa Pump and Compressor, an independent distributor, conducted an air audit and ultimately saved its customer, Progressive Foundry, $23,000 in electricity costs. It’s just one of many success stories on our case study web page outlining the benefits of an air audit by a qualified compressed air professional.

That’s why it is so crucial for Kaishan USA to partner with a nationwide network of independent distributors, who can provide on-site help and consultation as needed.

Audits conducted by these factory-trained air compression experts can help you achieve broader objectives, such as reducing downtime, lowering costs or developing a comprehensive maintenance program. We see the benefits of those audits every day.

Plus, our distributors can service your air compressor system without a problem. And they have staff members who are skilled in advanced technology. We partner with these independent, local distributors because it's the best way to provide expert guidance, faster response times and personalized support tailored to your needs. Their job is not just to sell compressors, it’s to build relationships, ensuring you get the right system, reliable service and quick access to parts when you need them most.

They have factory-trained technicians with a deep understanding of industrial applications, helping you maximize efficiency and minimize downtime. When you buy through Kaishan, you're getting more than a product—you're getting a local partner who cares about your business and will do what they can to help you succeed.

Key Takeaways

- The primary challenge in managing a compressed air system is getting the pressure “just right” and keeping it there.

- When the compressed air your system delivers does not reach the level recommended by the tool manufacturer, an air tool will not work correctly.

- If an air tool does not receive the recommended pressure, it will run more slowly, have less power, damage products, incur higher costs and be less productive. It may also suffer damage from increased wear and tear and present safety hazards.

- Increasing your compressor’s output to boost pressure to end users may have the opposite effect, because of the inverse relationship between pressure and flow.

- Low air pressure from the compressor may not be the only cause of poor air tool performance; the tool may need lubrication or may be wearing out.

- If you suspect that a tool is not receiving enough pressure, check the air pressure it is receiving and make sure the air delivery system is functioning properly.

- Before increasing header pressure, it’s a good idea to request an air audit from a compressed air professional.

Let Us Help

Delivering the required air pressure is crucial to the operation of your compressed air system and all the processes and air tools that rely on it. If you need help ensuring all your end uses have the air pressure they need, get in touch with the experts at Kaishan. Contact us today.

Listen to the Podcast Version

Why Pressure Matters

Alright, welcome back to The Big Dog Podcast, powered by Kaishan USA. I’m Jason Reed, and as always, I’m here with Lisa Saunders. Today, we’re talking about something that sounds simple but, honestly, trips up more shops than you’d think—getting your air pressure just right. Lisa, you remember your first week in maintenance? Didn’t you have a run-in with this exact problem?Oh, I absolutely did. I’ll never forget it. I was barely out of orientation, and I thought, “How hard can it be to keep the line running?” Well, turns out, if you mess up the pressure, you can shut down half the plant. I set the regulator too low—like, way too low—and suddenly, impact wrenches were just… sputtering. Bolts weren’t tightening, and we had to stop everything to figure out what was going on. I felt like I was gonna melt into the floor.

Yeah, and that’s the thing—impact wrenches, and honestly most air tools, are super picky about pressure. They want that sweet spot, usually 90 to 100 PSIG. If you’re under that, you’re not getting the torque you need. You might not even get the speed. And if you’re over it, you’re risking tool damage, safety issues, and just burning money for no reason.

Exactly. It’s like Goldilocks, right? Too much, too little—both are bad. I mean, if you’re running an impact wrench at 80 PSIG, you might as well be using a hand tool. But crank it up to 120, and you’re not just wasting energy, you could actually damage the tool or, worse, create a safety hazard. I read a case where a CNC machine lost clamp pressure after a power outage, and every single workpiece had to be scrapped. All because the pressure wasn’t right.

And it’s not just about the tools. If you’re running low, you’re losing productivity, you’re risking product quality, and you’re probably spending more on energy because the tool’s running longer to do the same job. And if you go too high, you’re just throwing money away on electricity and repairs. It’s a lose-lose if you’re not dialed in.

Yeah, and I think a lot of folks just assume, “Oh, the tool’s slow, let’s bump up the pressure.” But that’s not always the answer. Sometimes you’re just making things worse. We’ll get into that in a second, but the bottom line is—pressure matters, and getting it just right is the whole game.

Solving Pressure Problems

So, let’s talk about what actually causes those pressure problems. I mean, it’s not always the compressor, right? Sometimes it’s what we call the “dirty 30”—that last 30 feet of hose, tubing, and fittings before the tool. You can lose 30, even 50 PSIG right there if things aren’t sized or maintained right. That’s wild.Yeah, and don’t forget leaks. Even a tiny leak in a fitting or hose can kill your pressure at the tool. Or maybe the hose is too small, or the fittings are gummed up. I always tell people, start at the tool and work your way back. Check the pressure right at the tool first. If it’s good there, maybe the tool needs lube or it’s just worn out. But if it’s low, then you start looking for leaks, bad hoses, or undersized piping.

And here’s where people get tripped up. I had a plant manager once—good guy, but he thought he could just crank up the compressor to fix everything. So he bumps the system up, thinking more pressure will solve the problem. But because of the inverse relationship between pressure and flow, he actually made things worse. Less air was getting to the end of the line, not more. The impact wrenches were even weaker. It’s like, you gotta check the basics before you start messing with the whole system.

Totally. And if you do need to adjust pressure, do it as close to the tool as possible. Use a regulator right there, not at the compressor. That way, you’re not raising the pressure for the whole plant and running up your electric bill. Plus, the tool lasts longer if it’s not getting slammed with too much pressure all the time.

And don’t forget, sometimes it’s just a sizing issue. If your system was built for a worst-case scenario—like every tool running flat out, all day—you might be running way more compressor than you need, or you might have bottlenecks you never noticed. That’s where a little troubleshooting goes a long way. Check the tool, check the hoses, check for leaks, and only then think about the compressor settings.

Yeah, and if you’re still stuck, that’s when you start thinking about bringing in the pros. Which, funny enough, is exactly what we’re talking about next.

The Value of a System Audit

So, let’s get into audits. I know people hear “audit” and think, “Oh great, more paperwork.” But honestly, a professional air audit can save you a ton of money and headaches. There was that case with Progressive Foundry—after an audit, they saved $23,000 a year just on electricity. That’s not pocket change.Yeah, and it’s not just about finding leaks or bad hoses. A good audit looks at your whole system—sizing, demand, storage, even how your compressors cycle. Sometimes you find out you’re running way more pressure than you need, or you’ve got compressors fighting each other. The pros can spot stuff you’d never notice on your own.

And the best part is, when you work with someone like Kaishan’s network of distributors, you’re not just getting a report. You’re getting local support, factory-trained techs, and real help with implementation. They’re not just there to sell you a new compressor—they want your system running right, long-term.

So, when should you call in the pros? I’d say, if you’re chasing pressure problems more than once or twice a year, or if you’re seeing weird drops you can’t explain, it’s time. Or if you’re about to invest in new equipment and want to make sure your system can handle it. An on-site assessment should give you a clear list of issues, a plan for fixes, and a sense of what you’ll save—energy, downtime, all of it.

Yeah, and don’t be afraid to ask questions. A good audit should leave you with more clarity, not more confusion. And if you’re not sure where to start, reach out to Kaishan or your local distributor. They’ll walk you through it. Alright, that’s a wrap for today. Jason, always a pleasure.

You too, Lisa. And thanks to everyone for tuning in. Remember, getting your pressure “just right” isn’t just a nice-to-have—it’s the key to keeping your tools, your people, and your bottom line happy. We’ll catch you next time on The Big Dog Podcast. Take care, Lisa.

See you next time, Jason. And thanks to everyone listening—don’t forget to subscribe, and we’ll be back with more no-nonsense air system talk soon. Bye!

Random stat or

customer quote

textXXtext

text