Life Is Brewing

July 25, 2024

Airgas Puritan Medical

July 25, 2024CASE STUDY: NEW WATER-COOLED ROTARY AIR COMPRESSOR YIELDS 17% MORE AIR

AM/NS CALVERT

CALVERT, AL

The Situation

The 7,000,000 square-foot facility of AM/NS Calvert — a joint venture between ArcelorMittal and Nippon Steel Corporation — is one of the most advanced steel finishing facilities in the world. It produces a broad portfolio of steel grades for high-value applications, including hot rolled bands, hot rolled pickled and oiled, cold-rolled, and advanced coated products. Instrument-quality compressed air is used for a variety of production equipment and processes.

The Challenge

Catastrophic failure of an older air compressor meant the plant had to rent a compressor for a costly monthly rental fee, plus expensive diesel fuel.

A matrix of requirements for a new compressor was developed, but the plant’s hands were tied because the replacement would have to fit a tight footprint and limited power availability

The Solution

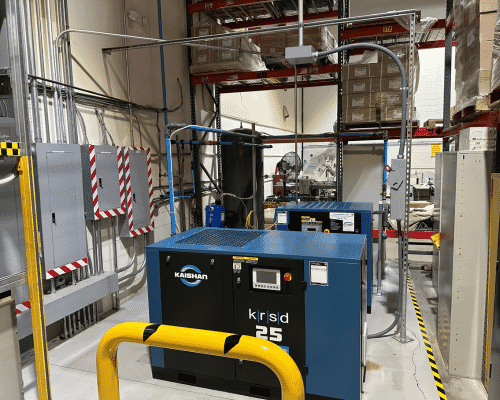

A two-stage Kaishan KRSP2-500-110 water-cooled rotary air compressor met the matrix of requirements. The design fit the footprint and power limitations, plus provided valuable maintenance advantages.

The Results

- Footprint: The KRSP2-500’s compact 153 in. long x 99 in. wide x 89 in. high dimensions enable an easy replacement in a tight mechanical room.

- Electrical: Kaishan was able to integrate the customer’s existing motor starter into their package, which made electrical installation a snap.

- kW Savings: Two-stage efficiency and high flow rate and low-power consumption (almost 5 CFM/HP versus 4 to 4.5 CFM/HP from typical single-stage compressors) reduce kW consumption by 8.5% (compared to other two-stage designs).

- Maintenance: Larger space inside the compressor for maintenance simplifies changing filters and performing routine maintenance.

- Lower cost of ownership: Lower kW consumption and enhanced maintenance reduces cost of ownership throughout life cycle.

- Factory-based training: Factory-trained technicians provide proper operation and maintenance (O&M) instruction.

- Warranty: Lifetime airend warranty covers the part of an air compressor that is the most expensive to replace and maintain.

- Sound: 82 dB provides a more manageable sound level for the mechanical room.

"For our 24/7 operation, the KRSP2 two-stage rotary air compressor has been running like a champ. It's a winner for efficiency, sound level, maintenance and footprint. Plus, it came with a lifetime airend warranty, including training, which moved it far ahead of competitors."

— Floyd Patterson, Senior Specialist Reliability Maintenance, CRM, AM/NS Calvert

More case studies:

Random stat or

customer quote

textXXtext

text