What is the Air Compressor Inlet Valve, and How Does it Work?

September 11, 2024

The Differences Between Air Compressor Preventive Maintenance and Predictive Maintenance. And Why You Should Care.

September 18, 2024CASE STUDY:

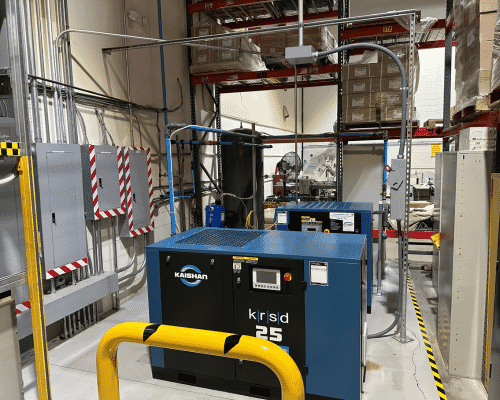

BILTWOOD POWDER COATING BOOSTS RELIABILITY, AVOIDS $10,000 PER DAY DOWNTIME WITH KAISHAN USA

Biltwood Powder Coating

Waynesboro, PA

The Situation

Biltwood Powder Coating works with manufacturers in Waynesboro, Pennsylvania, taking “old, ugly things and making them look new again,” according to owner Jim McCleaf. Those things include trailers, cranes, tow trucks and lifts made by local manufacturers, some of whom operate globally.

The Challenge

“We can’t do anything without having air to our powder guns,” Jim said. And not just the powder guns. They use compressed air to spray liquids, power grinding equipment and blow away dust and dirt.

As a result, his compressors run continuously, 10 to 12 hours a day, at least five days per week. Sometimes seven.

With one compressor aging and the concern expanding into a second building, Jim wanted to ensure he had compressed air when he needed it. He turned to his trusted air compressor distributor, Blue Mountain Air Compressor Services, in nearby Chambersburg, PA.

The Solution

Tom Yaukey, vice president and sales/service consultant at Blue Mountain, recommended replacing the aging unit with a 20-HP belt-drive Kaishan compressor with a receiver tank and a dryer.

The Results

- RELIABILITY: Blue Mountain handles all the maintenance, helping Biltwood avoid downtime that costs $10,000 per day. “We haven’t had any issues at all,” Jim said. “So, it’s kind of out of sight, out of mind.” Exactly the way he wants it. “This is how I run my business. I’m bringing somebody in, and I trust these people and they take care of it. I mean, that’s just the way it works with them. They take care of the service. It’s off my plate.”

- A PARTNER, TEAM MEMBER AND PART OF THE FAMILY: “I push the button, and it works. And everything from that point on, my day is easy. And that’s all I need to say. You got to have air to work,” Jim said. “I would recommend Tom and Blue Mountain to anybody. I feel like they’re a partner because when we call, they’re here for us and the service is impeccable. I don’t think about it ever.”

- CUTTING ELECTRICITY COSTS: “Because of the way Tom set that system up with a storage tank, we saved some money on electricity,” Jim said. “If I remember correctly, that was the first thing we noticed.”

- A GREAT FIT: The new system occupies a smaller footprint than the previous, an important issue because of space constraints.

- AMERICAN PRIDE: “We make our living off manufacturing that’s done right here in the United States,” Jim said. “So anytime and every time that we can, even if it costs a little more, we buy from the USA. We have to support the guys who keep our bellies full every month.”

“We make our living off manufacturing that’s done right here in the United States. So, anytime and every time that we can, even if it costs a little more, we buy from the USA. We have to support the guys who keep our bellies full every month.”

— Jim McCleaf, Owner, Biltwood Powder Coating

More case studies:

Random stat or

customer quote

textXXtext

text