Choosing the Right Rotary Compressor Oil

February 28, 2024

Ultimate Guide: What Is A Rotary Screw Compressor?

March 13, 2024Ten Need-to-Know Rotary Screw Air Compressor Maintenance Tips

Kaishan USA | March 6, 2024 | Uncategorized

Developing a comprehensive air compressor maintenance program is critical to reliable and efficient operation of your compressed air system.

If you want to keep your air compressor running reliably and efficiently, you need to take air compressor maintenance seriously. Industry research has proven that a proactive maintenance strategy can help you reduce maintenance costs by as much as 70%.

The ten critical air compressor maintenance items you’ll need to address on a regularly are as follows:

1. Change Air Filters Every 4,000 Hours

Inspect air filters every 2,000 hours and change them every 4,000 hours or per manufacturer’s recommendation or service indicators. Air filters remove particulates that enter your compressor’s intake, regardless of the air source. Dirty filters increase the pressure drop, making your system less efficient. Even a two-PSIG pressure drop caused by blocked filters will raise your energy consumption by an average of 1%.

Fortunately, a Kaishan compressor’s control system will monitor the pressure differential in your compressors intake air filter and oil filter and notify you of any problems.

2. Check the Oil Level Before Starting Your Compressor

Check the oil level using the sight glass before starting your compressor. Change oil filters every 2,000 hours of operation to remove metal filings, calcium and other materials in the oil and prolong its useful life.

Shorten the intervals for changing and sampling oil when you have demanding conditions such as high temperatures or dust and dirt in your intake air. And, when you’re using food-grade oil, you’ll want to sample your oil every 1,000 hours and take action on the recommendations in the analyst’s report.

Oil-free compressors, of course, do not have the same need for oil changes as oil-lubricated units, making air compressor maintenance less expensive for the first several years. However, after about five to seven years, they will need to be rebuilt, a labor-intensive project requiring expensive parts.

3. Clean Condensate Traps and Drains Daily

Inspect the moisture trap drain and the drains in all your tanks, filters and dryers. You’ll want to remove any scale, rust, dirt or other solids from condensate traps and drain points daily. Dirt and debris often accumulate in drains, causing them to become stuck. Stuck in an open position, the drain will leak air. And a closed drain will allow moisture and other impurities to pass through, contaminating your compressed air and possibly damaging production equipment.

4. Use Only OEM-Specified Oils and Lubricants

It’s so central to the operation of your compressor that we consider rotary compressor oil the lifeblood of your system. And it’s why we place so much importance on selecting the right oil for our compressors. For more on choosing the right oil for your compressor, read our blog post, “Choosing the Right Oil for Rotary Air Compressors.”

Failing to use our oils and lubricants will invalidate your warranty.

5. Change the Oil Separator and Lubricant Every Year, Every 8,000 Hours or as per Machine Guidelines.

Change the oil separator and lubricant every 4,000 hours if it’s a spin-on type and annually or every 8,000 hours of operation if it’s a standard drop-in type. Or as indicated in your oil-sampling recommendations. Check the oil separator pressure differential and replace it if the pressure drop through the separator is over 10 PSIG. Once again, a two-PSIG pressure drop caused by blocked filters will raise your energy consumption by an average of 1%.

And don’t forget to check the scavenge line! Clogged scavenge lines and orifices are the top cause of oil carry-over.

6. Sample Oil Every 2,000 Hours or 1,000 Hours for Food Grade Lubricant.

We require that our customers collect an oil sample and have it analyzed every 2,000 hours to maintain their warranty protection.

There are two critical readings you’ll see in your oil analysis:

-

- Viscosity by ASTM D 445 measures the thickness of the fluid. We expect viscosity to increase as you use your compressor. That’s how the oil keeps possible contaminants in solution, preventing varnish or solids from “dropping out” of the fluid.

- Total Acid Number indicates how much acid has formed. Once again, we expect it to increase as the oil ages.

For more on oil sampling, read our blog post, “Choosing the Right Oil for Rotary Air Compressors.”

7. Repair System Air Leaks as Quickly as Possible

Compressed air systems typically lose between 30% and 50% of their volume to air compressor leaks, with poorly maintained systems running as high as 80%. As a result, one of your first tasks is determining how many leaks you have—and fixing them as quickly as possible.

Ultrasonic leak detection devices can help you pinpoint sources of leaks in your compressed air system.

Newer, visual, acoustic imaging devices known as ultrasonic leak detection systems use multiple directional microphones to triangulate the position of a leak source, overlaying the leak’s ultrasonic “signal” on a video image of your plant.

For more information on fixing links, see our blog post, “How to Find and Stop Air Leaks.”

8. Use Only Quality OEM Parts

Using our recommended industrial air compressor parts will allow you to improve your compressor’s life expectancy and reliability. We engineer and manufacture genuine Kaishan parts to support and enhance your compressor’s performance. That longevity extends not only to the compressor, but also to its components and the end-use tools it serves.

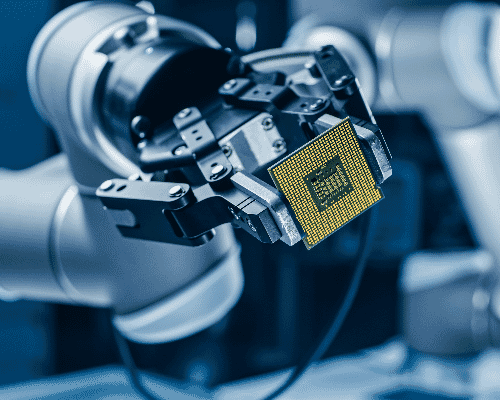

They conform to stringent specifications and performance standards, going through the same quality-control testing as our compressors. That’s critical in delivering the high-quality air expected in industries such as food processing, semiconductor and electronics.

Using genuine OEM spare parts and fluids helps you meet stringent compressed air quality standards, such as those in the semiconductor industry.

Almost all compressor manufacturers, including Kaishan, require that you use their original OEM parts to maintain your warranty eligibility. Any perceived short-term savings you realize by purchasing aftermarket parts could ultimately raise your lifecycle costs, resulting in higher energy use, increased downtime and more frequent replacements as well as potentially voiding your warranty. As Compressed Air Best Practices notes, “The money you save by purchasing generic parts is often the most expensive money you will ever save.”

For more information on the replacement parts, read our blog post, “How to Maintain Your Air Compressor with Genuine Spare Parts.”

9. Maintain Your Warranty Eligibility

Use original OEM parts and fluids to maintain warranty eligibility and ensure your air compressor system operates safely at the expected performance level.

Because of their reliability, efficiency and long life, Kaishan rotary screw air compressors have the best warranties in the industry. Our standard warranty covers the complete compressor package for 12 months from the date of startup (or 18 months after it’s shipped, whichever comes first), with an airend warranty of 24 months.

And, on our KRSP and KRSP2 screw compressors, Kaishan offers a lifetime warranty on the airend.

Kaishan backs its KRSP and KRSP2 screw compressors with an unmatched lifetime airend warranty.

As mentioned, our extended warranties require that you use genuine Kaishan industrial air compressor parts. Using generic or aftermarket parts/fluids will void the warranty.

For more information on warranty eligibility, read our blog post, “How to Maintain Your Air Compressor with Genuine Spare Parts.”

10. Adopt a Consistent Air Compressor Maintenance

Following a consistent air compressor maintenance plan will ensure that you deliver high-quality compressed air, save money and prolong the life of your air compressor and the other components in your compressed air system. It may even extend the service life of the equipment you’re powering.

Unfortunately, advanced technologies, like ultrasonic leak detection, are beyond the scope of most in-house air compressor maintenance teams. According to recent research, in fact, many companies are finding that they no longer have the expertise in-house to deal with the complexities of today’s advanced equipment like air compression systems.

That’s why having a relationship with an air compressor maintenance professional is so important. Someone with the most up-to-date equipment and a lot of experience using it. We strongly advise companies to seek outside help when issues arise to avoid serious problems and bring in a professional anytime you see a drop in performance you can’t explain.

We would encourage you to work with your local independent air compressor consultant rather than agree to an all-inclusive air compressor maintenance contract offered by some factory-direct outlets. We’ve always found that your local consultant will give better service at a more reasonable rate, especially when you establish a relationship.

Having a skilled professional help you develop an air compressor maintenance program is one of the most cost-effective steps you can take to ensure the reliability and long service life of your compressed air system.

Finding A Local Consultant

We work with a nationwide network of independent distributors, who can help you set up an air compressor maintenance program that will meet your needs. They have trained professionals skilled at using advanced equipment like ultrasonic leak detection.

Key Takeaways

-

- Change air filters every 4,000 hours or per manufacturer’s recommendation or service indicators.

- Check the oil level before starting your compressor.

- Clean condensate traps and drains daily.

- Use only OEM-specified oils and lubricants.

- Change the oil separator and lubricant every year, every 8,000 hours or as per machine guidelines.

- Sample oil every 2,000 hours or 1,000 hours for food-grade lubricant.

- Repair system air leaks as quickly as possible.

- Use only quality OEM parts.

- Maintain your warranty eligibility.

- Adopt a consistent air compressor maintenance.

Let Us Help

Maintaining your rotary screw air compressor is critical to the reliability and performance of your compressed air system and all the processes that rely on that system. If you need help getting started with an air compressor maintenance program, get in touch with the experts at Kaishan. Contact us today.

Random stat or

customer quote

textXXtext

text