Reasons Why You Should Be Monitoring Air Compressor Data

October 11, 2023

Kaishan USA Launches New Industrial, Oil-Free Rotary Screw Compressor

October 23, 2023Air Compressor Monitoring Tools for a Smart Factory

Kaishan USA | October 18, 2023 | Uncategorized

Companies can use smart factory data acquisition and analysis to monitor their air compressors, saving money, cutting downtime and improving efficiency.

Tiny sensors built into small, lightweight pneumatic devices allow measurement across the factory floor. Even the simplest devices provide crucial performance data, such as temperatures, pressures, flow rates, cycle times, valve response rates and more.

All that data can now be put to good use, giving us an unprecedented opportunity to monitor your air compressor system. And even do it remotely.

Our previous blog post, “Twelve Reasons Why You Should Be Monitoring Air Compressor Data,” outlined the benefits of capturing, analyzing and applying the insights from air compressor data.

The good news is that the same drive to capitalize on this rich information resource (and put it to good use) is behind the smart factory movement and related approaches like the Industrial Internet of Things (IIoT) and Industry 4.0.

Why to Connect Your Air Compressor to Your Smart Factory

As noted in our previous post, making good use of the data now available from your air compressor can pay huge benefits, including the following:

-

- Save money. Optimize your system, cut downtime, increase equipment life, and create a safer environment for your team. All those things pay off financially.

- Cut downtime. Maintain your system to its highest level of performance, optimize operations and avoid costly breakdowns that damage equipment and shut down your plant.

- Improve reliability. Improve operation of your air compressor and all the related equipment like filters, dryers and coolers.

- Monitor your system remotely. Enjoy 24/7 remote access to your air compressor data, tracking system performance and identifying readings that are out of spec. So you can fix problems before they start.

Most monitoring systems allow 24/7 remote access to air compressor data.

-

- Get alerts and notifications. Receive notifications when your pressure drops, electricity consumption rises too abruptly or air quality begins to drop. Giving you time to take corrective action. Logging trends helps identify anomalies such as excessive leaks or misuse of pneumatic equipment.

- Enhance efficiency. Identify issues limiting system performance—your pressure band is set too high, or your system is rapid cycling, wasting energy and shortening equipment life.

- Be proactive. Schedule preventive maintenance before an issue becomes a problem.

- Optimize performance. Tweak system operation and get everything running according to design.

- Lengthen equipment life. Identify equipment issues such as rapid cycling. Or receive an alert when oil changes and oil sampling are required, or your compressor is not operating within its design parameters.

- Enhance safety. Identify equipment issues well before they reach the breaking point. And avoid accidents that result in damage, lost production and even injuries to your staff.

- Comply with regulations. Many state and local regulators require periodic system checks such as tank inspections. And most manufacturers require regular maintenance procedures (e.g., oil sampling) to keep warranties in force.

- Make maintenance a priority. As with all the other equipment in your plant, your air compressor needs attention occasionally. Your data monitoring system will issue alerts and notifications when maintenance is required. Good maintenance, in turn, more than pays for itself in improved performance, greater reliability and reduced downtime.

The bad news is that capturing and using that data takes some effort. The good news is that we’ve advanced well beyond the stage where data collection is manual. We now have the benefit of techniques and approaches coming out of the smart factory movement and the digital revolution in general. Let’s review the options.

Smart Factory Monitoring Tools

There are three main ways to take advantage of the data your air compressor is generating.

AirWatch

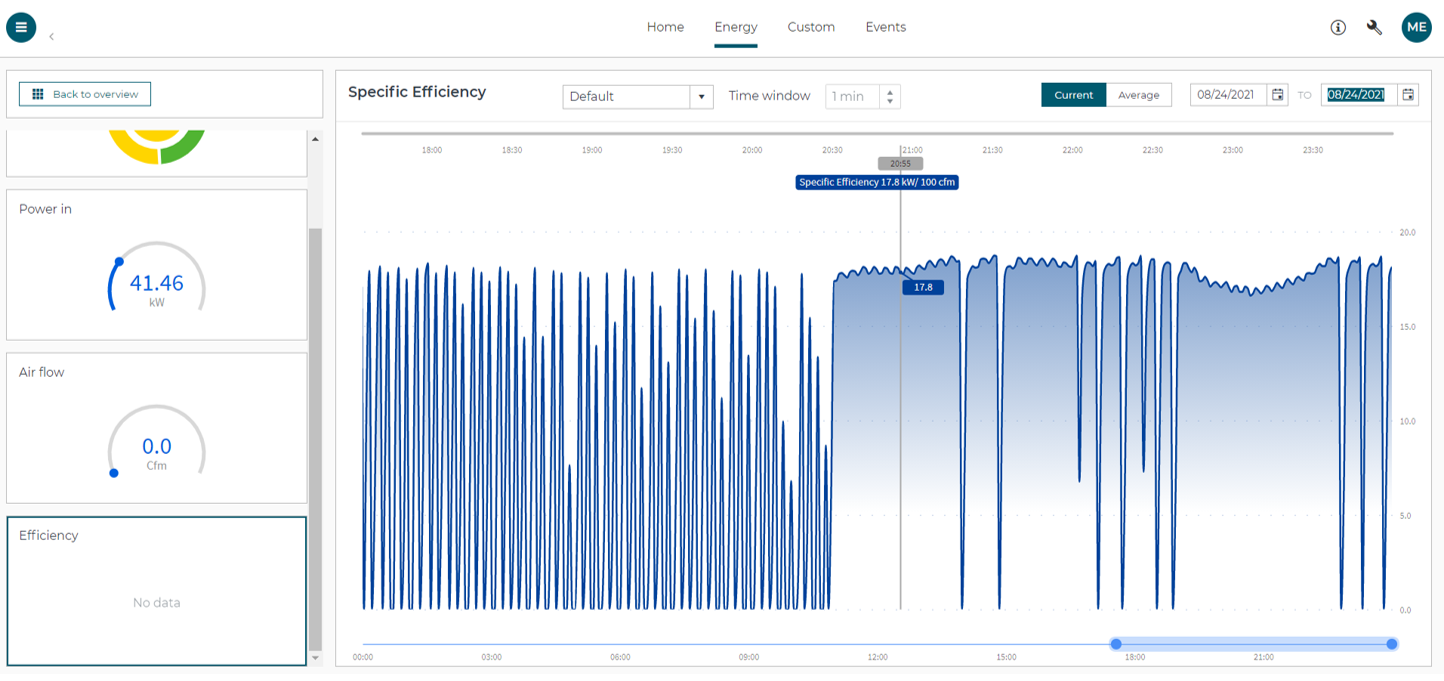

Our most advanced connection is through our AirWatch system, which uses a wireless-based cellular modem to allow real-time monitoring of your air compressor data through any connected device, from a desktop to a cell phone. The wireless approach is a game-changer in that it avoids the nightmare of going through your IT department, enterprise software system and factory automation infrastructure.

The AirWatch base unit is available on our KRSD, KRSP, KRSP2, KRSL, KRSV and KROF and premium rotary screw air compressors.

Instead, you put an antenna on each compressor and link it to its own data hub, which accesses the internet through a cellular connection that only has to be within 330 feet of the unit. That allows you to circumvent the noise and interference often found on the factory floor. You can do that with every compressor in your facility and your organization, giving you total access from a laptop, cell phone, tablet or desktop computer. To any machine in your organization worldwide.

The AirWatch Wireless modem is an edge device that can be mounted remotely to make it easier for you to access its signal.

With AirWatch’s cloud-based compressor monitoring software, you’ll have full access to your compressor, seeing what’s happening in real-time:

-

- Set alarms

- See what maintenance is scheduled

- See current energy use

- Check readings for dew point, dryers or pressure (you can even add flow measurement, for an additional cost)

- Change the time interval from day to week, to month to year

- Review trends

You can customize alerts about warnings and shutdowns and format logging and trend analysis according to your preferences. You can even customize the delivery method, having emails or text messages sent to an individual or group.

The software also is flexible enough that you can create your own custom reports, following the key performance indicators you have identified.

With AirWatch, you can access any machine in your organization worldwide.

Say there’s a pressure problem in a remote area of the plant. Using AirWatch, you can quickly learn if it’s a clogged filter or something more serious. On the other hand, you can check to see if your variable-speed-drive-enabled compressor is running often enough. Or conversely, it’s running too often, meeting base load demand when it should only be operating as a trim unit in its sweet spot. You may even find that your oil temperature is running over 120° in the spring, indicating a need for corrective action before the dog days of summer.

AirWatch allows you to monitor individual compressors, such as this VSD-equipped unit, to determine if it’s being used effectively.

Plus, you can share access to that information with a distributor, consultant or even someone from our technical support organization. For distributors, it offers the opportunity to do proactive servicing with their customers, alerting them to issues before they become problems. It exponentially expands your opportunity to anticipate problems before they shut down your air compressor system.

AirWatch sets the default for a report at one day. But it is easy to set the date range.

You will have 24/7 access with 360° visibility into your air compressor’s status, allowing you to optimize its performance and efficiency. It’s almost like having a continuous audit. (For more on the benefits of audits, see our blog post, “How an Air Compressor Audit Can Reduce Operating Costs.”

With a simple cellular connection, you’re smart factory, Industry 4.0-ready. But more importantly, you’ll have the peace of mind that comes from knowing your vital “fourth utility” is being monitored around the clock. With minimal security concerns and IT department involvement.

With our AirWatch system, you can even give a consultant access to the air compressor data.

Modbus-Level Controls

You can also connect the parts of your air compressor system, including compressors, dryers and other equipment, using a Modbus interface. Then, control your devices with the software of your choice.

Modbus is a communications protocol widely used in industrial settings to exchange data between devices. It is brand-agnostic, creating a standard, low-cost data format to link equipment from different manufacturers.

Kaishan equips its KRSP and KRSP2 premium rotary screw air compressors with a Modbus-compatible control system allowing them to work with almost any communications protocol. As a result, they are fully compatible with virtually any remote monitoring system.

Programmable Relays

Kaishan compressors are also equipped with programmable relays that allow you to link them together to coordinate their activities. You can set parameters to balance the workload between compressors and monitor system performance measurements like pressure, flow, temperature and electrical use.

And you can set up remote monitoring and alerts without involving your factory automation system or information technology department. So, there are no security issues and you can still get some alerts.

The cost is small, and the demands on your IT department are minimal. Plus, in the event of a power failure, your measurements will come back online at the same time as your automation program.

More Than One Brand?

In our experience, most companies have air compressors from more than one manufacturer. And while it may not be possible to monitor several of these compressors with a single cellular line, it is possible to have multiple units connecting to a single hub, allowing you to access all these connected compressors from that hub.

Indeed, you can't network equipment from different manufacturers if you rely on the network control software that comes with your air compressor. Usually, you can only link devices from the same manufacturer using these systems.

As noted above, Kaishan’s KRSP and KRSP2 premium rotary screw air compressors are equipped with a Modbus-compatible control system allowing them to work with almost any communications protocol. As a result, they are fully compatible with almost any remote monitoring system.

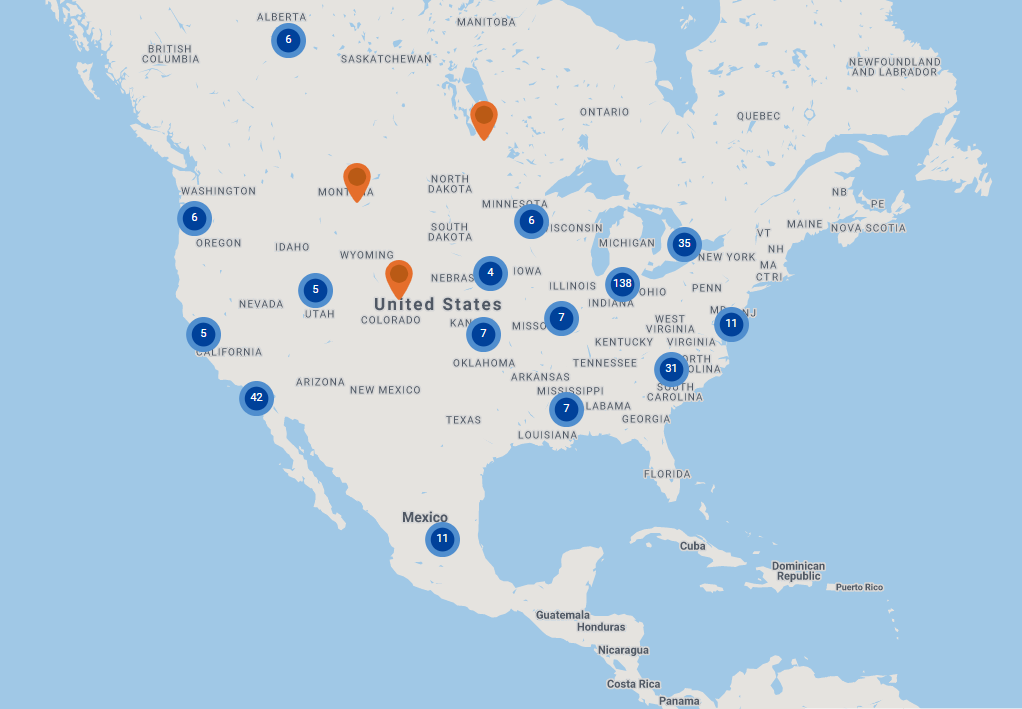

Local Help

Not sure why, when and how to monitor your air compressors or how to connect into your smart factory? We can help. Kaishan USA works with a nationwide network of independent distributors, who can provide on-site help and consultation as needed. These factory-trained air compression experts have an investment in their local communities and can help you find the best air compressor monitoring approach for your application.

Key Takeaways

-

- Pneumatics lends itself well to data collection and application.

- Analyzing your air compressor data, as with smart factory systems, can help you lower costs, prevent downtime and improve efficiency.

- Our AirWatch system gives you real-time monitoring of your air compressor data through any connected device.

- You can monitor your air compressor system using a Modbus interface.

- Kaishan compressors are equipped with programmable relays that allow you to link them together.

Let Us Help

Monitoring your air compressor data in a smart factory is critical to the operation of your compressed air system and all the processes that rely on that system. If you need help selecting the right approach for your system, get in touch with the experts at Kaishan. Contact us today.

Random stat or

customer quote

textXXtext

text

Companies can use smart factory data acquisition and analysis to monitor their air compressors, saving money, cutting downtime and improving efficiency.