Unverferth Manufacturing Co.

July 25, 2024

Air Compressor Oil Filtration: Preserving Air Quality and Prolonging Equipment Life

August 7, 2024How Energy-Efficient Air Compressors Can Reduce Your Carbon Footprint

Kaishan USA | July 31, 2024 | Uncategorized

Air compressors offer a wealth of opportunities to reduce your carbon footprint.

Five Sure-Fire Ways Energy-Efficient Air Compressors Can Reduce Your Carbon Footprint

It may seem a little strange to use air compressors to reduce your carbon footprint and boost your sustainability efforts.

Admittedly, compressed air is not the most efficient power source. But there’s no question that compressed air still has a crucial role in industry today. Places where electricity or natural gas would be hazardous. And in powering the precision movements that makes pneumatics vital in a host of industries.

As a result, it’s critical that companies today have their compressed air systems running as efficiently as possible. Saving energy, eliminating downtime and reducing waste.

We outline five ways below to increase your compressed air system’s efficiency, reliability and cost-effectiveness.

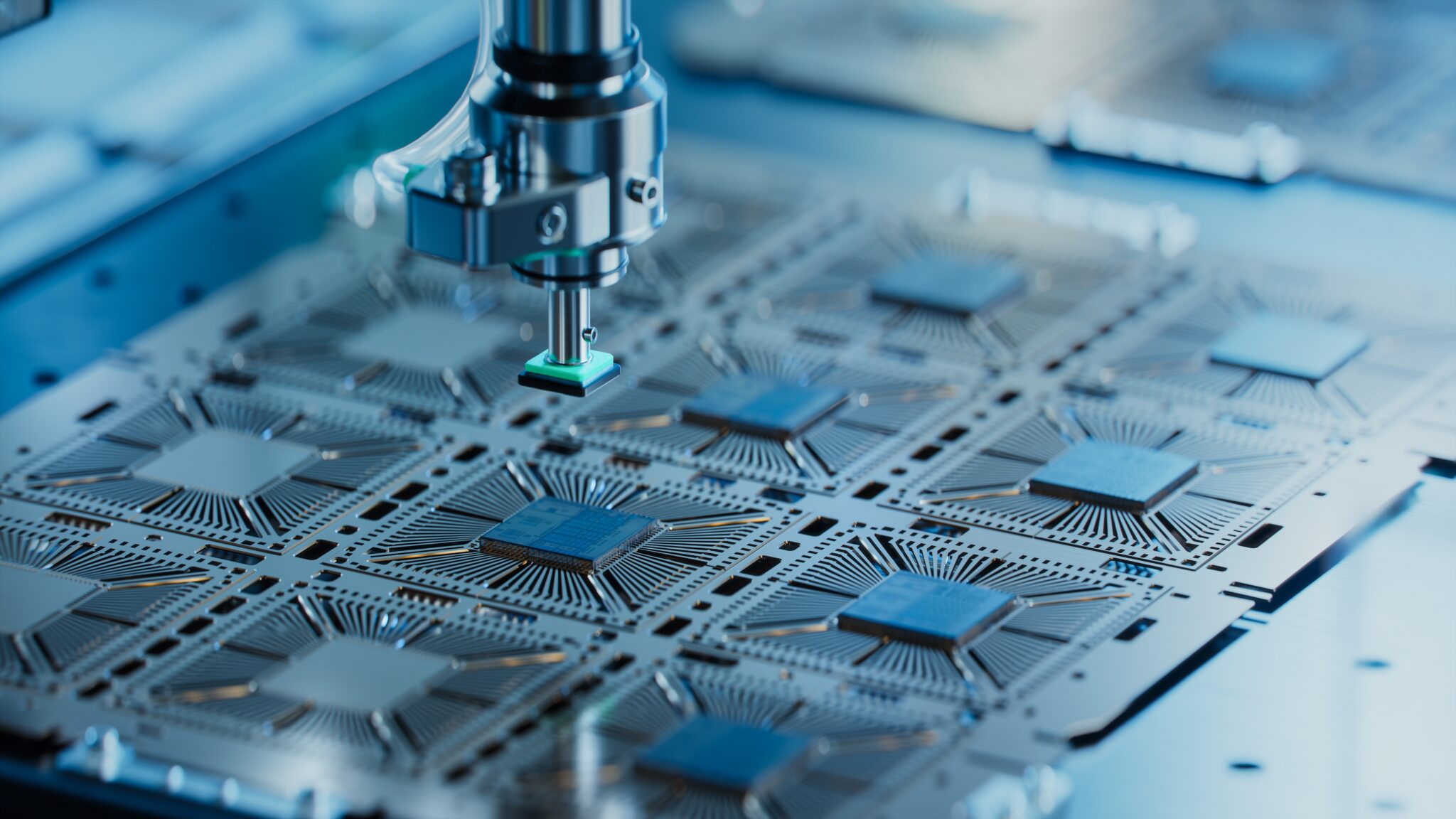

Two-stage compressors, such as Kaishan’s KRSP2, deliver the reliable, energy-efficient air needed for applications like electronic manufacturing.

1. Two-Stage Compressors

A single-stage compressor like Kaishan’s KRSP premium rotary screw air compressor generates a compression ratio of 7.8 to 1 to create 100 PSIG of pressure. It is one of the most cost-effective compressors on the market, and Kaishan backs it with an industry-leading lifetime airend warranty.

Kaishan’s KRSP single-stage rotary screw air compressors are among the most cost-effective and efficient options on the market.

On the other hand, a two-stage air compressor like the KRSP2 premium rotary screw air compressor splits the workload into two separate stages—a first stage of 2.8 to 1, followed by a second stage of 2.8 to 1. Plus, before the second stage, the air passes through an interstage cooling step, removing some of the heat of compression and building efficiency.

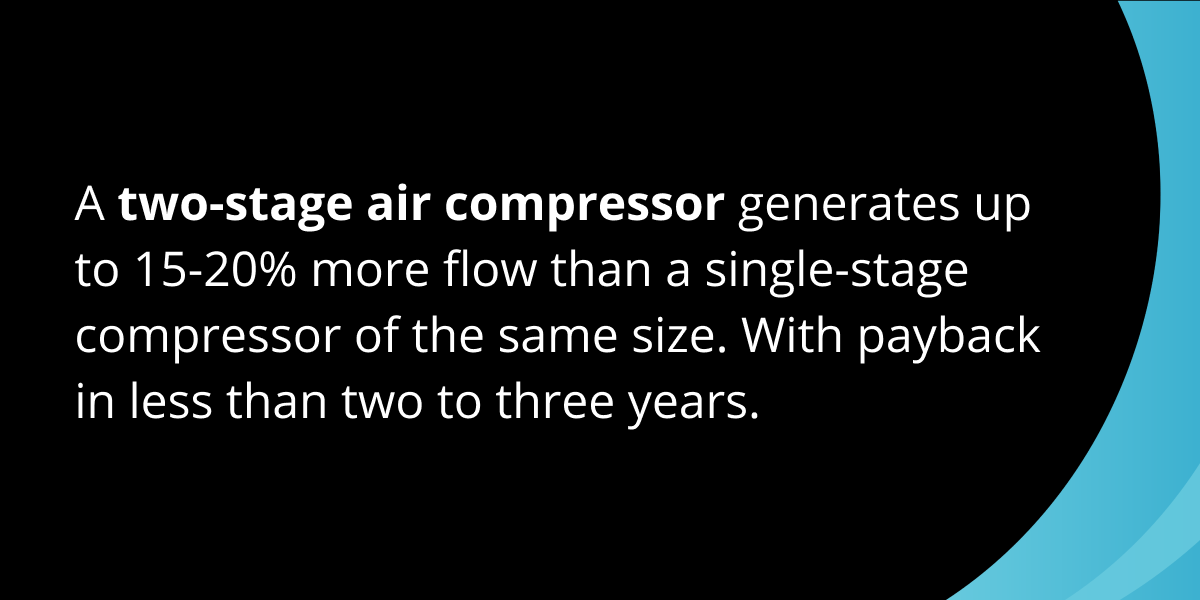

This improved efficiency enables the KRSP2 to generate more compressed air for less energy, specifically, more compressed air per kW of power. The bottom line? A two-stage air compressor generates up to 15 to 20% more flow than a single-stage compressor of the same size (HP). Paybacks on energy costs alone may be less than two to three years.

Kaishan’s KRSP2 two-stage rotary screw air compressor is one of the most energy-efficient machines on the market.

More Reliable and Long-Lasting

In addition, using two stages results in less mechanical stress and lowers the temperatures in each stage because the work is split, reducing wear and tear and extending the life of components. Similarly, because the KRSP2 spreads the work over two stages with four discharge bearings on the first stage and three on the second stage, those bearings have less stress than the two bearings that carry the entire thrust load in a typical single-stage unit. (Our single-stage KRSP, however, has four bearings as well, three thrust bearings and one radial bearing.)

Lower forces and more bearings result in longer life. Both the KRSP and KRSP2 are built to last, enabling us to offer an industry-leading lifetime airend warranty. And further reducing your carbon footprint by eliminating waste and scrap.

In addition, because a two-stage compressor generates 15 to 20% more compressed air flow than a comparable single-stage unit, you may be able to use a model with a lower horsepower. You may, for example, be able to replace a 300-HP single-stage compressor with a 250-HP two-stage KRSP2.

2. Multiple-Compressor Configurations

We often encourage customers to adopt at least a three-compressor approach involving base, trim and backup units.

-

- A base load compressor to meet your system’s minimum compressed air load. Its output does not fluctuate as demand goes up and down. Instead, it runs full bore—at 100% of capacity—or it turns off. Depending on variations in your demand, you may have more than one unit as a base load.

- A trim compressor to handle fluctuations in demand above the base unit. Since the level of flow needed will rise and fall depending on the needs of your system, rotary screw compressors equipped with variable-speed drives are a natural for this application.

- A backup compressor on standby if a base or trim unit goes offline. To fill in appropriately, it should be the same size as the base load compressor.

Configuring your compressed air system in this way virtually eliminates unplanned downtime, which, in the real world, is the biggest (and most avoidable) expense associated with your compressed air system. A highly reliable rotary screw air compressor always waits in the wings as a backup should a base load or trim unit fail, keeping both pressure (PSIG) and flow (CFM) more consistent and reliable.

And while you may be reluctant to invest in additional units, remember that equipment costs are only a 12% fraction of the total lifetime costs of owning an industrial air compressor, according to the U.S. Department of Energy.

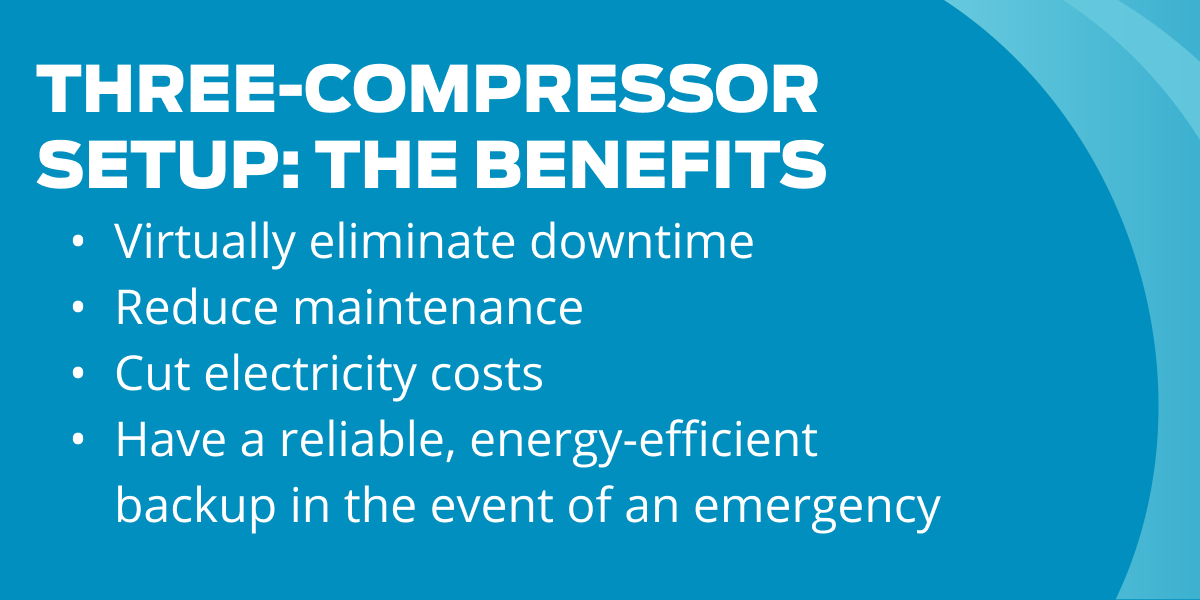

Other savings you can realize with a three-compressor setup include:

-

- Maintenance. You extend your service hours because you don't need service as frequently. Instead of quarterly, you can do it semiannually.

- Electricity. Two smaller compressors will be more energy efficient unless you have consistent air demand, which is typically not the case. And since a large portion of the total cost of ownership of an industrial air compressor comes from electrical bills, even a slight improvement in energy use could save the price of a backup. Typically, the largest motor in most manufacturing plants is on the air compressor.

- Emergency service. Plants without backup units often rent portable diesel units when a main compressor breaks down. Using a diesel backup is harmful to the environment, producing a lot of emissions and costing two to four times more. Plus, it typically doesn’t have an aftercooler, so it sends dirty or wet air into your system, usually more than your cleanup equipment can handle. There are also significant savings in maintenance and operating costs: a portable diesel compressor will need oil and filters every 250 hours. If you’re operating 24/7, that could mean they require maintenance every ten days. And then there’s a problem of supplying the unit with diesel fuel every 12 hours!

3. Variable Speed Drives

The application of VSD technology to rotary screw air compressors has enabled many companies to save significant amounts of energy.

VSD technology is almost tailor-made for rotary screw air compressors, enabling them to operate more efficiently at part-load conditions. You really can’t apply VSD technology to reciprocating air compressors because you can’t adjust speeds the way you can with a rotary screw unit.

Energy savings are not the only benefit. VSD compressors can earn rebates, allow soft starts and offer better control of your compressed air system. They are also an energy-efficient way to address rapid cycling, which occurs when your air compressor switches back into the loaded state before the transition to the no-load state is complete. If that happens too frequently, it can cause increased wear and reduce compressor reliability and lifespan.

VSD technology allows better control of your air compressor, enabling higher air quality, which is a “must-have” in medical and healthcare facilities, where air quality is paramount.

Not for Everyone

While government bodies and utilities have gone all-in on VSDs, offering attractive rebates and incentives to companies that deploy them, they are not for every application.

In fact, they may cause more problems than they solve for some compressed air users. We have seen many circumstances where a company paid more for a VSD-driven compressor to earn the rebate. But the results were less than satisfactory.

As a result, we’ve become strong advocates for applying VSD technology everywhere that’s appropriate. They are not a good choice at the extremes:

-

- At high levels, when your compressor runs at 100% load most of the time, the drive itself incurs some losses, making it less energy efficient.

- At low levels, A VSD air compressor will run too cold and build up moisture, ruining the machine. So, we encourage customers not to use a VSD compressor when the machine runs at 20% of its total capacity most of the time.

The bottom line? VSD technology can cost you money if it is not applied appropriately. It has a higher initial cost than a fixed-speed compressor. Plus, frequent breakdowns often occur when a VSD compressor is not the right choice for the application.

There is no question VSDs can save you a boatload of money, in the right application. As a result, we’ve become strong advocates for applying VSD technology everywhere that’s appropriate. But more importantly, we’re totally against misapplying VSDs.

4. Fix Leaks

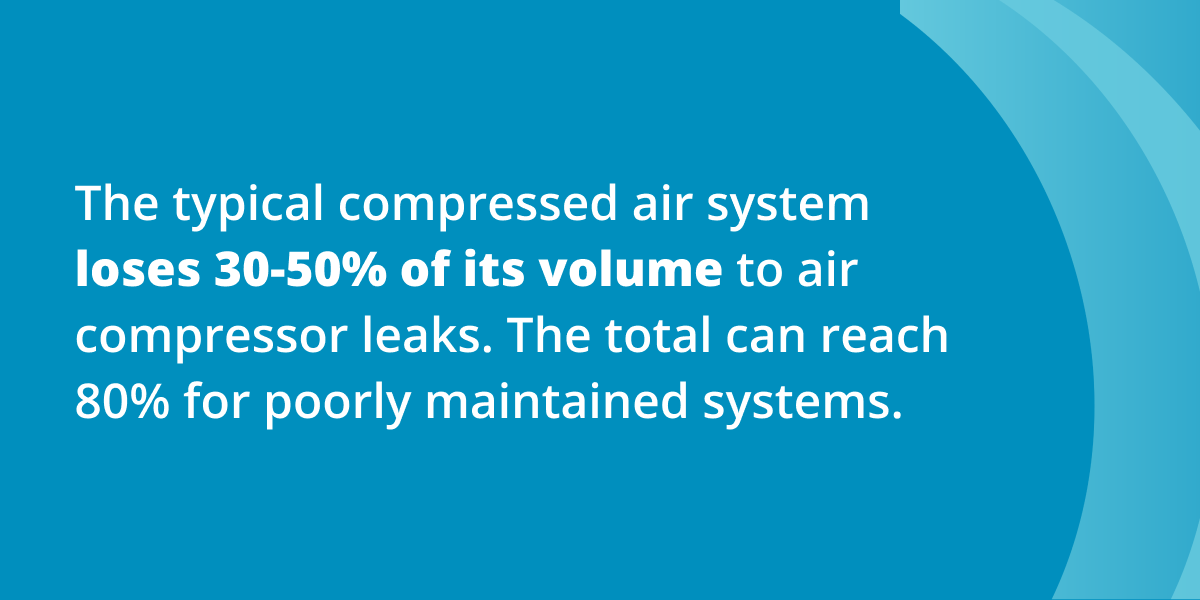

No air compressor efficiency effort would be complete without addressing leaks. The typical compressed air system loses 30-50% of its volume to air compressor leaks. And the total runs as high as 80% for poorly maintained systems. (For more information, visit our recent blog post on the topic, “Air Compressor Leaking? How to Find and Stop Leaks.”

Poorly designed and maintained compressed air systems waste up to $3.2 billion in utility payments in the U.S. annually, according to the Compressed Air & Gas Institute. CAGI further estimates that a quarter-inch leak in a 100-PSIG system will cost at least $17,000 annually. Perhaps more, depending on your local utility rates.

The good news is that some leaks are easy to locate because they emit a notorious, hard-to-ignore hissing sound. The bad news is that most don’t make any sound at all. In fact, 80% are inaudible.

Handheld leak detection devices have been available for some time and have been successful at helping companies locate leaks that are not in the audible range. Unfortunately, they also pick up signals from end-use tools or other ultrasonic emitters like cathode ray tubes, fan blades, pumps and vacuum pick-ups. That’s why the industry is turning to ultrasonic leak detection devices.

Ultrasonic Leak Detection

Unfortunately, few companies have the resources to purchase the latest technology or the need to train staff in its use. Ultrasonic leak detection devices are well beyond the scope of most facility maintenance teams. That’s why we recommend that our customers establish a relationship with a local compressed air professional with the most up-to-date equipment and experience in identifying and quantifying air leaks.

For more on leaks, read our blog post, “Eight Causes of Compressed Air Leaks and How to Find Them.”

5. An Air Audit

One critical step in launching your expense-reduction strategy is choosing a compressed air professional to help you.

An audit by an air compressor professional is a great place to start any program to reduce your carbon footprint. We’ve documented situations in which customers cut their energy use and saved tens or even hundreds of thousands of dollars in our blog post, “How an Air Compressor Audit Can Reduce Operating Costs.”

Most of the issues mentioned above, including using a two-stage compressor, switching to a three-compressor configuration, implementing a VSD air compressor and repairing leaks, would be addressed in an audit by an air compressor professional.

Members of Kaishan’s nationwide network of independent distributors, have the skills and the equipment needed to conduct a comprehensive audit of your compressed air system. They have experienced technicians on staff who are skilled in analyzing your system and using leak-detection technology to identify leaks.

Key Takeaways

-

- A two-stage air compressor generates up to 15-20% more flow than a single-stage compressor of the same horsepower with a payback in less than two to three years.

- We often encourage customers to adopt a three-compressor approach involving base, trim and backup units.

- VSD technology has enabled many rotary screw air compressor users to save energy, but they are not for everyone.

- No air compressor efficiency effort would be complete without addressing leaks.

- An air audit is a great place to start your program to reduce your carbon footprint.

Let Us Help

Reducing your operation’s carbon footprint is critical to the success of your company and to the planet. If you need help improving the sustainability and energy efficiency of your compressed air system, get in touch with the experts at Kaishan. Contact us today.

Random stat or

customer quote

textXXtext

text