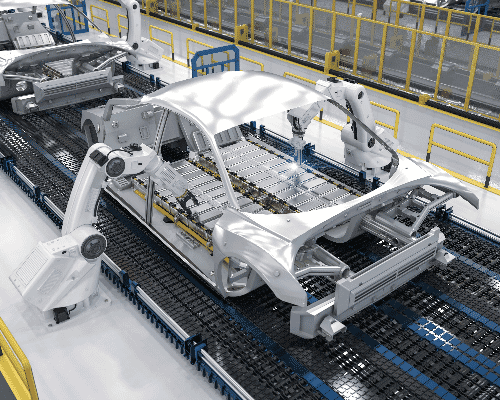

Choosing the Right Air Compressors for Electric Car Battery Manufacturing

May 29, 2024

Why and How Winemakers Are Using Industrial Air Compressors

June 12, 2024Industrial Vacuum Pumps Prove Their Value in Woodworking

Kaishan USA | June 5, 2024 | Uncategorized

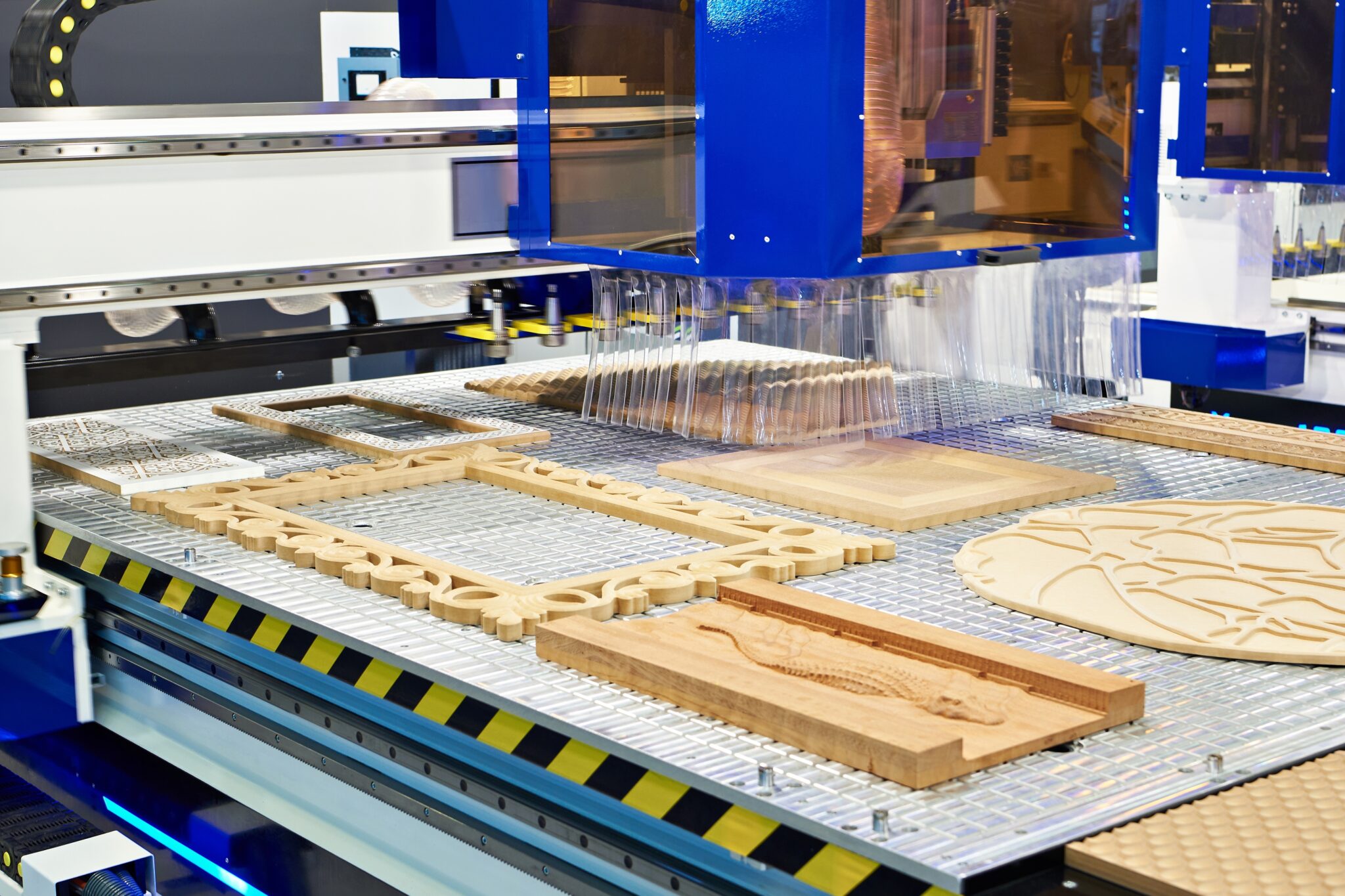

Vacuum technology plays a vital role in the woodworking industry.

Industrial vacuum pumps play an essential role in the woodworking industry, impacting energy costs, maintenance costs and downtime. Even productivity.

Vacuum technology is involved in a variety of woodworking processes, such as laminating, veneering, polishing and drilling. However, the most critical application of industrial vacuum pumps is holding a workpiece in place on a router table. As the computer-controlled head executes the cuts and designs, the vacuum created by the pump keeps the piece in place without leaving pressure marks.

Vacuum technology holds workpieces in many areas of woodworking.

What makes it challenging is that the cutting action of the head injects a lot of sawdust and dirt into the air, all of which the vacuum system sucks in. As a result, vacuum systems need to be designed to remove that debris before it gets to the pump.

In addition, the load on the pump varies quite a bit. When the woodworker has the workpiece in place, the flow is reduced, so the pump decreases in speed. But when the worker removes it when the cutting is complete, the pump begins pulling in atmospheric air, increasing the load.

To handle that kind of fluctuation, most manufacturers equip industrial vacuum pumps with a variable-speed drive.

When a worker removes a workpiece from the machining center, the load on the system suddenly changes, creating a challenge for the industrial vacuum pumps.

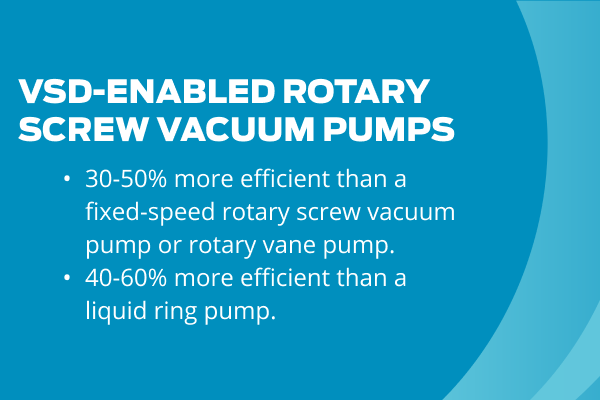

Variable-Speed Drive

A rotary screw vacuum pump is a textbook case for the use of a variable-speed drive. Here’s why.

With a fixed speed pump, when there is a part in place on the router table, and the vacuum pulls it tight, the vacuum level increases, and the pump will operate at the same speed even though the demand is reduced. Then when the operator changes parts, a large amount of air is allowed into the system and the pump demand is at a maximum. However, with a variable-speed drive, when there is a part in place and the vacuum pulls it tight, the vacuum level will remain the same because the VSD slows the pump to a minimum speed, saving energy. When air is allowed into the system, the pump speeds up again.

It thus increases the flow and decreases power consumption at the required vacuum levels. As a result, VSD-enabled industrial vacuum pumps are 30-50% more efficient than a fixed-speed rotary screw vacuum pump or rotary vane pump and 40-60% more efficient than a liquid ring pump.

Many woodworking operations have router bed isolation valves or other systems in place to stop rapid changes in system pressure. This approach requires setting the beds up properly so that unused portions are not exposed to atmosphere, "blanking" the part of the bed that is not being used.

In addition to VSDs, Kaishan has added a new twist—a variable-discharge port—to our industrial vacuum pumps to meet changing demands like those in woodworking.

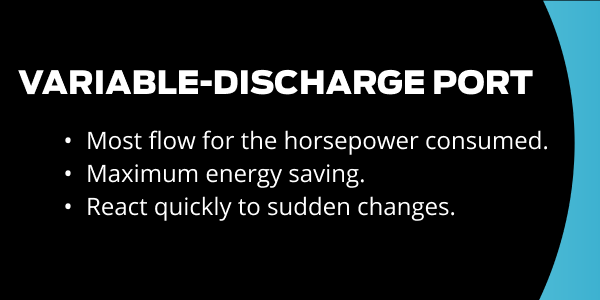

Variable-Discharge Port

Most other industrial vacuum pumps on the market today have a fixed discharge port, with a compression ratio established by the manufacturer. So, when you select a pump, you choose the pump size based on either the volume you need at startup or the level you will want at the desired vacuum. As a result, you have to choose between efficiency at the beginning or at the end of the process.

When it needs to create a deeper vacuum (it needs more flow to reach the desired vacuum level), the valve opens the port—reducing the compression ratio. Closing it increases the compression ratio.

The variable-discharge port makes the change on the fly, increasing the pump’s volumetric efficiency and performance. It also allows a rotary screw vacuum pump to operate efficiently at any point within its range, making it especially beneficial for applications such as woodworking, where the vacuum level varies over time.

You start the pump with the discharge port wide open. Then, the variable-discharge port slowly closes as the vacuum level rises and the pump draws deeper into vacuum. The device balances the compression ratio and maintains it in an ideal range. It keeps the pump from over-compressing the air, doing work that is not required at that moment. As the pressure changes, the port immediately adjusts to ensure maximum efficiency, the perfect size all the time. Thus, the compression ratio stays at the optimum level at all pressures.

Another advantage is that the variable-discharge port can react quickly when the vacuum dramatically decreases, which might happen if several processes come online simultaneously.

Here’s how that works for the router table example we mentioned at the beginning of this post.

In a typical woodworking plant, vacuum applications are in the low or rough vacuum range, 20 to 25 inches of mercury. (For more details on industrial vacuum pumps, read our blog post, “Industrial Vacuum Pumps: Applications and Benefits.”

When you take the part off the table, your vacuum level goes from 25 inches of mercury to the atmospheric level. So, the variable-discharge port opens. When you put another part on the table, it goes back down to 25 inches and the port slowly closes.

More importantly, however, an industrial vacuum pump with a variable-discharge port will give you better control of your machine during fluctuating vacuum levels. A variable-discharge port is standard on all our KRSV vacuum pumps.

Now, let’s talk about how VSDs and variable-discharge ports work together.

VSD and Variable-Discharge Port, the Combination

An industrial vacuum pump equipped with variable-discharge port and a variable-speed drive will achieve maximum flow and energy savings at any level within its operational range.

A variable-discharge port responds quickly when you start it up, enabling you to achieve a high level of flow for the horsepower consumed. It combines with the variable-speed drive to give you great flow and energy savings at all vacuum levels.

The VSD-variable discharge port combination also adds a level of protection. If the system goes quickly from full vacuum and full demand to ambient pressure levels, a VSD alone will not slow down quickly enough. As a result, the unit would over-amp, either causing nuisance alarms or harm to the motor. The combination of the VSD and variable discharge port keeps this scenario from happening.

Types of Industrial Vacuum Pumps

Many plants have several small, point-of-use rotary vane vacuum pumps, each attached to a different application. However, many are finding that they are neither efficient nor cost-effective.

First, rotary vane pumps require frequent maintenance and repair, usually every 500-2,000 hours, with repairs usually costing 60% of the purchase price. Multiply that by the number of applications (and pumps), and you have a significant cost. A service nightmare. And a lot of downtime.

On the other hand, a rotary screw vacuum pump will last 16,000 to 20,000 hours before any significant repair is required. Rotary screw vacuum pumps equipped with a VSD and a variable-discharge port deliver tremendous advantages when compared to the smaller rotary vane vacuum pumps many plants use today. Plus, without the VSD, a rotary vane pump or even another rotary screw vacuum pump will not be able to handle partial loads.

As a result, plants that eliminate their point-of-use rotary vane pumps and centralize their vacuum systems with a rotary screw vacuum pump can save on electricity bills and avoid frequent, avoidable maintenance costs—ending high energy costs and the constant repair and replacement of multiple rotary vane pumps.

Instead, you’ll substitute an industrial-strength vacuum capability that matches the rough vacuum needs of all your equipment.

Rotary Screw Vacuum Pumps: Benefits Summary

-

- Low energy consumption. Pumps equipped with VSDs and variable-discharge ports optimize the energy required to perform at various vacuum levels, thereby increasing overall efficiency.

- Low maintenance costs. The lower maintenance costs cut the total cost of ownership for rotary screw vacuum pumps.

- Automatic alerts. The pumps automatically alert you when performance falls below a specified threshold. Sophisticated microprocessor controls allow you to fine-tune machine operation to meet your needs.

- Low noise. Many rotary screw vacuum pumps are quiet enough to hold a conversation nearby.

We’ve created the KRSV rotary screw vacuum pump to handle demanding applications such as woodworking.

Kaishan’s KRSV: VSD, Variable-Discharge Port

Kaishan’s KRSV is the only industrial vacuum pump on the market with both VSD capability and a variable-discharge port. It perfectly matches the needs of the woodworking industry while reducing both maintenance and electrical costs.

This design delivers the greatest efficiency in CFM per horsepower—providing the most flow for the horsepower consumed at every vacuum level and thus keeping electricity consumption stable.

With both VSD capability and a variable-discharge port as standard features, Kaishan’s KRSV gives you an unequaled operational range (with turndown capabilities up to 90% of maximum), helping you avoid the need for blow-off. It can scale down to 10% of full load, matching the vacuum output to the plant’s CFM demand and saving significantly on energy costs. We had one recent plant where the savings on energy costs alone delivered a payback in nine months!

And there’s more.

Rotary screw vacuum pumps are known for outstanding reliability and longevity. And our KRSV rotary screw vacuum pump combines a variable-speed drive with a variable-discharge port, making it highly efficient over a wide range of pressures and operating flows.

An Oil Pump Allows Quick Startup

Most competitive vacuum pumps rely on differential pressure to provide lubrication. However, if a process requires frequent stops and starts, going quickly from full vacuum and full demand to ambient pressure levels, there is no differential pressure, and, hence, no oil flow. So the pump has to start slowly to build up that pressure.

Addressing the problem more directly, Kaishan’s KRSV’s standard oil pump begins moving oil on startup, allowing you to ramp up to maximum RPM quickly, without the risk that the unit will not have adequate lubrication. As a result, you can begin working almost immediately, saving you time between pieces.

That difference could boost your productivity significantly.

Local Help in Optimizing Vacuum Performance

The best approach is to bring in an expert to help you determine the right industrial vacuum pump for your application. Or whether your organization would benefit from a centralized vacuum capability.

Kaishan USA works with a nationwide network of independent distributors, who can provide on-site help and consultation as needed. These factory-trained industrial vacuum pump experts can analyze your needs and make recommendations to optimize vacuum delivery throughout your plant.

Key Takeaways

-

- Industrial vacuum pumps play an essential role in the woodworking industry, impacting downtime, productivity, energy use and maintenance costs.

- VSD vacuum pumps can help you match vacuum flows to your plant’s demand.

- Variable-discharge ports change the size of the discharge port, maximizing volumetric efficiency at multiple vacuum levels.

- Kaishan’s KRSV is the only industrial vacuum pump on the market today offering a VSD and a variable-discharge port.

- Oil pumps can help prevent overheating by maintaining consistent oil flow independent of vacuum pump speed.

- Only Kaishan’s KRSV combines all these advances to help you increase uptime and productivity and lower energy use and maintenance costs.

Let Us Help

Finding the right industrial vacuum pump for your operation can help you save money, cut downtime and reduce maintenance costs. If you need help finding the right pump for your application, get in touch with the experts at Kaishan. Contact us today.