Keeping Vacuum Costs Down

July 10, 2024

How to Choose the Best Air Compressor for Wastewater Treatment

July 24, 2024What To Do When Your Air Compressor Is Not Building Pressure

Kaishan USA | July 17, 2024 | Uncategorized

Your compressed air system may look like controlled chaos. But, most likely, you’ll find it has a logical organization once you understand it.

We’ve all been there. Your air compressor is running. Everything looks normal. But your air compressor won’t build pressure at your end-use applications. Or at least, you’re not getting enough.

In other words, the lights are on, but nobody is home.

Now what?

Usually, the end-use guys are screaming for air. Your production manager is in your face, and the plant manager is looking at his watch. Your stress level (not to mention your blood pressure) skyrockets. It’s not a good place to be.

So, the first step is to take a deep breath. At this point, things usually seem much worse than they are.

The main reason? Your compressed air system may seem like organized chaos (with some question about the organized part). And it might feel intimidating to unravel what feels like a hodge-podge of equipment, piping and end uses. But we’ve found most compressed air systems follow a few basic principles. They’re all fairly logical.

So, put your plant manager and his watch out of your thoughts and tackle this thing rationally. You can do this—even if your air compressor is not building pressure.

We start at the beginning with the most basic questions. And take one thing at a time.

One of the first issues is to address a common misconception: the confusion over pressure (PSIG), flow (CFM) and power requirements (HP). Because of the inverse relationship between pressure and flow, trying to increase the pressure at a remote end-use by boosting the pressure your compressor probably will produce less air at the targeted application. If you need a refresher on pressure and flow requirements, read our blog post, “How Many CFM Do I Need? Air Pressure by Different Applications.”

If you’re comfortable with those distinctions, move onto the next step, making sure your compressor is actually working.

Are you sure your compressor is actually working? If your air compressor is not building pressure, that’s a great place to start.

Air Compressor Won’t Build Pressure? Start Here.

Compressors can be sneaky devils. The lights can be on. The display might be lit.

There’s noise and vibration going on. But, of course, it’s an equipment room. Which means there’s lots of moving and shaking.

The display might be on, but your compressor may not be working. In fact, even the most experienced professionals can be fooled. So, your first task is to make sure it is actually operating.

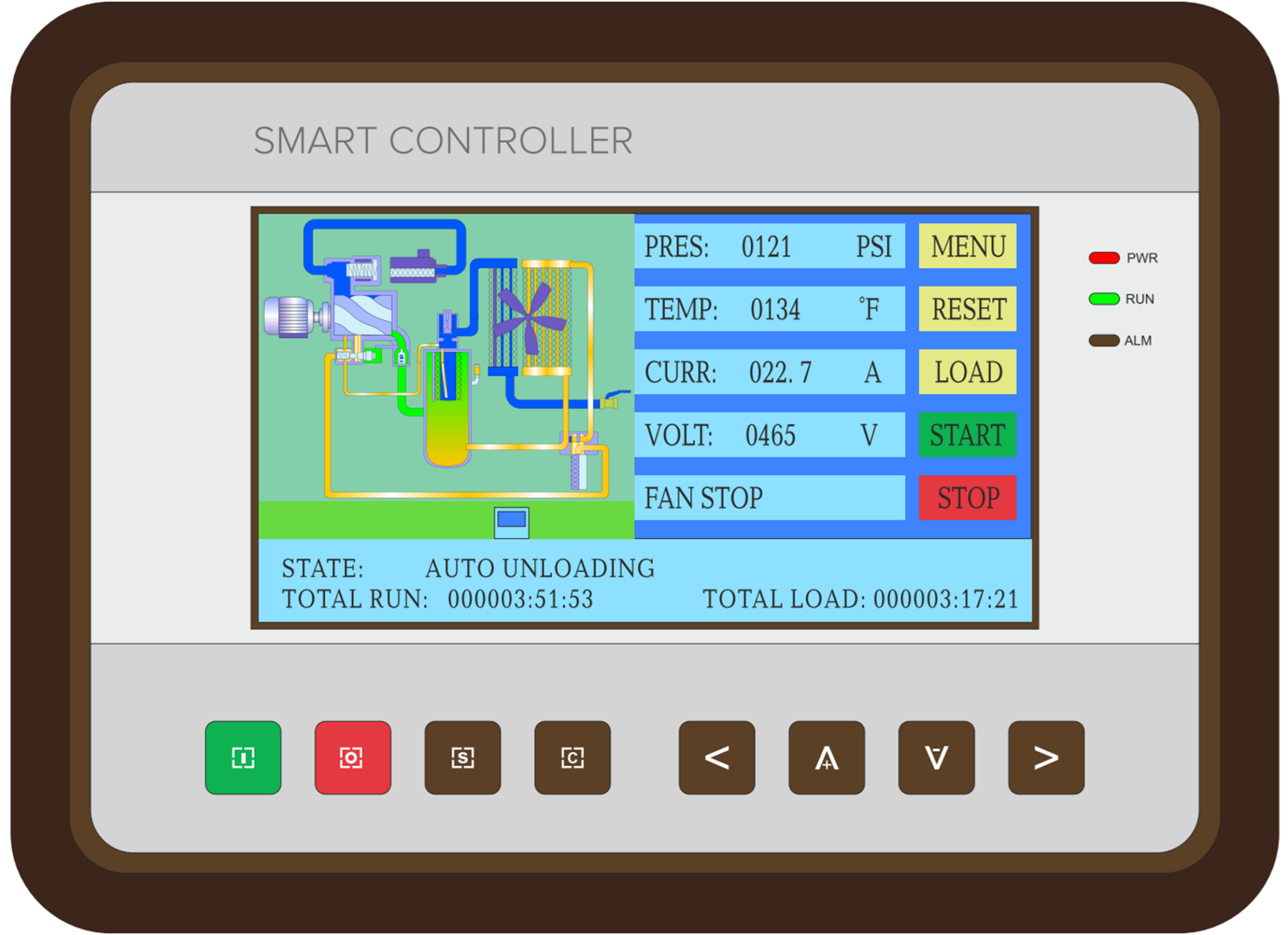

The display of this Kaishan KRSP2 shows the unit’s power consumption.

With a Kaishan compressor, that’s easy. Your display shows the amount of power being consumed in kWh. Close the valve to your system and the power consumption should rise to your compressor full horsepower rating quickly. However, it will unload quickly thereafter because pressure will build up and put your compressor in an unloaded state until you open the valve again.

Most likely, it will. And if your air compressor is not building pressure, that means the issue is likely somewhere else in your system. However, if it does not show the full horsepower rating, the problem is with the compressor. We’ll cover that situation later.

Unfortunately, almost no other compressor manufacturer displays the power consumption on the screen the way we do. For us, it is primarily a safety issue. We believe it’s important that you know how much power your compressor is consuming (since actual measured motor amps is one of the first diagnostic steps we do). You shouldn’t have to stop production or put people in harm’s way to get that data. So, we think compressor manufacturers should put it at your fingertips.

We display your compressor’s power consumption prominently to help your people service your machines safely.

If you don’t have a Kaishan compressor, you can determine whether it is producing air by isolating it from the demand. One way is to do a pump-up test.

Pump-Up Test

A pump-up test helps answer the question, “Why is my air compressor not building pressure?” by confirming whether it’s generating air at all. First, empty the tank and close the service valve at the discharge. Next, measure how long it takes to achieve the desired pressure (PSIG). Then, plug the data into a pump-up test calculator such as this one from the Compressed Air and Gas Institute, which will tell you whether your compressor is making the amount of air it’s designed to deliver, based on how long it took to fill the tank.

If you’re only checking to make sure your compressor is working, you can also slowly valve off the machine and see if it starts making air:

-

- If it does not, you know your compressor is the issue. Once again, jump to the section below, “The Problem Is in Your Compressor.”

- If it does, then know your problem is in the plant at large. In other words, the plant is using more air than the compressor can deliver, or what is known as over-demand.

Once again, that may seem like a hopeless task. But it is not a big deal. As the old joke says, “How do you eat an elephant?” One bite at a time.

How Do You Fix an Air Compressor That’s Not Building Pressure?

Typically your plant does not just wake up one day and consume significantly more air than the day before. Chances are there is an upset condition somewhere or somehow.

So, in the same way you isolated your compressor from the demand, you should split off the various lines as they come off the main piping from your compressor. Most likely, the problem is a leak somewhere, so you may want to review our blog post, “Eight Causes of Compressed Air Leaks and How to Find Them.”

Moving away from the compressor, you can cut off the valve at each run and see what happens to the pressure. You should start with a receiver tank and move on from there. Valve off the receiver tank and let the compressor fill it.

If you’ve established that your air compressor is not building pressure because of a problem in the plant, work outward from the compressor, cutting off valves for each line until you find the one that’s the problem.

Then proceed down the line, cutting off valves for each line until you find the one that’s the problem. When you do, the pressure will return to normal levels. That will allow the rest of the plant to return to work while you fix the problem you’ve just identified.

Occasionally, though, you’ll find that your problem is in your compressor.

The Problem Is in Your Compressor

Compressors can be complex. But if your air compressor won’t build pressure, you may be able to fix it yourself by checking a few common causes. Some possible issues to consider:

-

- Filters. Filters should probably be on the top of the list. You can chase down an issue for a long time and realize the problem is in the beginning. The air is coming in, it's getting hot. Everything seems fine. But the pump-up test isn't working well, because your air filter is clogged. When air filters get clogged, there’s usually additional power draw but not a decrease in air flow. We even see the hoses connecting the air filter to the inlet collapse.

- Process inlet valve. Every compressor on the planet has a valve to allow air to go into the compressor. You’ll want to make sure it is working correctly and not clogged.

- Mechanical issues. If it’s a belt-drive compressor, is the belt loose or even broken? Are the fittings or lines broken or missing?

- Solenoids. It’s always good to check the solenoids. But the fact that they’re just sitting there doesn’t mean they’re broken. They might not be energized, and, as a result, they’re not the problem.

- Noises. Is the compressor making any unusually loud noises?

- Leaks. Both inside and outside the compressor, LEAKS ARE ALWAYS AN ISSUE.

- Heat. A working compressor should be about 185°-190°F, slightly uncomfortable to the touch. If it’s not hot, there’s a problem.

Local Help for More Serious Problems

If your air compressor is not building pressure and the issue is beyond routine maintenance, it’s smart to work with a compressed air professional. They can also help ensure you don’t invalidate your warranty by attempting repairs that need professional attention. For more on warranty coverage, read our post, “How to Maintain Your Air Compressor with Genuine Spare Parts.” Or for more tips on maintenance and troubleshooting, go to the post, “Top Air Compressor Problems and How to Troubleshoot Them.”

Kaishan USA works with a nationwide network of independent distributors, who can provide on-site help and consultation as needed. These factory-trained air compression experts can service your air compressor system without a problem. And they have staff members who are skilled in advanced technology.

Key Takeaways

-

- Make sure your compressor is actually running. Even the most experienced professionals can be fooled.

- If your air compressor is not building pressure in your system, start by checking to make sure it is running.

- On a Kaishan compressor, your display shows the amount of power consumed in kilowatts, making it much easier to determine if your compressor is operating.

- For most other compressors, you will have to do a pump-up test to confirm that the compressor is generating the pressure it’s designed to deliver.

- If you are having a problem out in the plant, you can find it by cutting off valves for each line until you find the one that’s the problem.

- If the problem is in your compressor, you will want to look for blocked filters, leaks, clogged process inlet valves, leaks and mechanical problems such as broken belts (on belt-drive compressors).

- If you need help determining why your air compressor is not building pressure, your local compressed air professional can offer valuable assistance.

Let Us Help

When your air compressor is not building pressure, it’s critical to get your compressed air system back in operation as soon as possible. If you need help determining how to get your system working quickly, get in touch with the experts at Kaishan. Contact us today.