The Future of Energy Efficient Manufacturing: Rotary Screw Air Compressors

April 17, 2024

Kaishan USA Holds Groundbreaking for Expansion

April 24, 2024Top Air Compressor Problems and How to Troubleshoot Them

Kaishan USA | April 24, 2024 | Uncategorized

Working with a skilled compressed air professional can help you avoid many air compressor problems.

Over the years, the compressed air industry has fielded thousands of air compressor problems. Late-night calls. Frantic emails. Texts over holidays or weekends.

And while each one is unique, a few key themes emerge:

-

- The control screen is displaying a service alarm.

- The machine is over temperature.

- The machine is not producing air, doesn’t respond to a start command or is showing a shutdown condition.

Let’s discuss these air compressor problems in a little more detail.

Alerts that your system needs service are the most common air compressor problems we hear about. Usually, there’s nothing wrong. But that doesn’t mean you can ignore them.

The Control Screen Is Displaying a Service Alarm

Most midnight calls are about a simple service alarm. It’s the number one air compressor problem we get.

It may happen because the machine has reached it hourly threshold. Or any number of other status conditions. So, there may not be an immediate issue, but you still need to take action.

The best way to respond is to schedule a service call. It may be something simple—your machine needs a new oil filter, for instance.

But talking to your trusted consultant may save you time, money and downtime. Here’s why.

The first question your service provider will ask is, “What other alarms are present?”

They can help you ensure that there aren’t any other service intervals coming up and that you’re dealing with all of them, not just the one that came up.

So, you’re not just replacing that oil filter and then getting an alert a few days later that it’s time to replace your air filter. Incurring more downtime while you shut down your system and wait for a replacement part.

Your local service provider can help you prevent that. They can also help you with overheating issues, the second major air compressor problem we hear about.

The Machine Is Over Temperature

If your compressor is not operating because it exceeded the shutdown temperature, most likely it’s because it’s low on oil. You’ll be tempted to add some oil and be up and running again as quickly as possible. But that’s not a good idea for the following reasons:

-

- You need to think about your warranty. In the event of a warranty claim, your manufacturer will review the fault history to ensure that you handled temperature shutdowns appropriately. What happened, and what did you do about it?

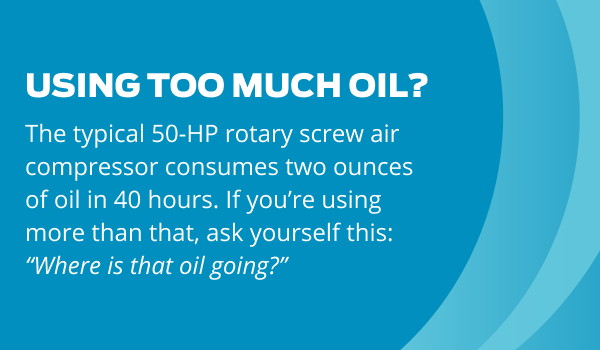

- You need to find out where that oil went. A typical 50-HP rotary screw air compressor barely consumes two ounces of oil in 40 hours. If you’re using more than that, there’s probably a problem in the machine. One that you can’t ignore. Oil can spread out in a thin coating that’s hardly noticeable, but it’s probably not on the ground. And if it’s not in your compressor, it’s probably in your process somewhere. You’re removing it in the air-oil separator. Or, worse yet, it’s downstream, in the air you’re delivering to your applications, wreaking havoc with your end-use air tools and equipment. Not good, in other words. If you’re using too much oil, you need to find out where it’s going.

- For all those reasons, you should probably start with your local service representative. Your manufacturer will probably require that they sign off on any warranty claim, verifying that any temperature shutdowns were addressed. That there’s no question the issues were addressed appropriately. So, save time and go right to the source.

The issue could be that your compressor is oversized or misapplied. We’ll address that one later.

The last item on our top-three list of air compressor problems is that your machine isn’t making air for some reason. Or it doesn’t respond to a start command.

The Machine Is Not Making Air or Doesn’t Respond to a Start Command

It’s not saying anything is wrong; it’s just not making air.

You’ll start by confirming that the machine is, in fact, running. The controller might say it’s running, but it may not be.

It’s especially a problem when you have multiple machines. It’s not unusual for a machine’s controls to say it’s working, and the sound of the other machines leads you to believe it’s running full tilt. But it’s not.

There are two possibilities: you aren’t getting full rotation. Or you are.

If You Aren’t Getting Full Rotation

If you’re looking at the screen and all the green lights are on, you can be fooled.

Check the temperature. It should be 150 degrees or higher. If it’s not—if it’s closer to room temperature—the machine’s not running.

If you can see there’s no mechanical transfer of rotation, the cause is probably mechanical. You could have a loose coupling or a broken belt. So, the fix is a simple replacement.

If You Are Getting Full Rotation

If you are getting full rotation, however, something else is going on. And it’s a lot more complicated, so it’s best to bring in your air compressor professional.

If you’re getting rotation and your temperature is where it should be, you’re probably making air. It’s probably escaping into the atmosphere in a leak somewhere. It could be in the compressor room, or it could be a filter or drain stuck open.

But most likely, it’s out in the plant somewhere. Perhaps in an end-use application. And your plant is so noisy that you’re not hearing it. For more on the important of finding and fixing leaks, see our blog post, “How to Find and Stop Air Leaks.”

To find out, close your isolation valve and see if the pressure rises. If it does, you’ve confirmed that the compressor is making air and the problem is in the system at large.

Other Air Compressor Problems

A few other issues crop up, including moisture in the air and oversizing or misapplication of your compressor.

You’re Getting Moisture in Your Compressed Air

Most of the time, water carries over into your system because a drain is clogged. Dryers, after all, are designed to remove water vapor or aerosols, not liquid. So, when a drain is clogged, some of that moisture carries over. If you do an air quality sample and find a lot of moisture in your air flow, the dryers and drains are the most likely culprit.

In addition, a lot of companies run into problems because they turn off their refrigerated dryers at night, and it takes the dryer an hour or two to get to the right temperature.

You should also do an oil sampling. Persistent moisture in an oil sample is the best indication that your compressor is oversized for your application.

Fluid sampling is critical to the life of an oil-flooded rotary screw air compressor. Sampling oil regularly will tell you whether it is being exposed to excessive heat or taking in contaminants. It can also detect excessive bearing wear, allowing you to be proactive when you uncover a problem, even avoiding an unplanned shutdown.

We consider oil sampling the most critical maintenance procedure for our compressors. And we require that, to maintain their warranty protection, our customers collect an oil sample and have it analyzed every 2,000 hours or every 1,000 hours for food-grade applications. For more on oil sampling, read our blog post, “Choosing the Right Rotary Compressor Oil.”

Oversizing and Misapplication

The most serious air compressor problems come from mistakes in sizing or application. Be careful not to oversize your system, trying to add more “muscle” to your system or anticipate future needs. It may seem counterintuitive, but with rotary screw air compressors, “too much” is almost as bad as “not enough.”

Here’s why. Rotary screw air compressors are designed for a 100% duty cycle. Run them significantly less than that, and you’ll waste energy. Oversizing is the leading cause of rapid cycling, which occurs when your compressor turns on and off constantly and causes equipment failures and downtime. For more on the topic, read our blog post, “Seven Strategic Ways to Reduce Expenses from Compressed Air.”

The good news? An oversized or misapplied machine is not the end of the world. There are many things you can do to correct the situation. But it requires the assistance of a trusted advisor to put together a plan that you should follow rigorously. With the right plan, you can avoid costly downtime and machine failures.

A trusted partner can help you avoid the most serious air compressor problems. They can even help you set up a consistent maintenance program.

The key is to avoid air compressor problems before they start.

Preventing Air Compressor Problems Right from the Start

The best time to prevent air compressor problems is before you buy a machine. We recommend the following steps to get you off on the right foot:

1. Get a trusted partner. They can help you avoid the most serious problems by ensuring you have the right machine, sized correctly, for your application.

2. Have a service plan and follow it carefully. Following a consistent air compressor maintenance plan will ensure that you deliver high-quality compressed air, save money and prolong the life of your air compressor and the other components in your compressed air system. It may even extend the service life of the equipment you’re powering.

Many companies have daily checklists their maintenance team should follow to assure that their air compressor is running properly.

Our most successful customers use checksheets or checklists covering all the basics. You’ll want to look for the following:

-

- Faults

- Pressure

- Temperature

- Hours

Adding those things to a daily checklist can help you identify issues before they become air compressor problems.

Creating the right environment in your compressor room can help avoid air compressor problems.

3. Choose your location carefully. The layout of your equipment room can help ensure your compressed air system’s longevity, performance and cost-effectiveness. For more information on the right setting for your machine, read our blog post, “Compressor Room Design.”

Your Local Professional Can Help

As mentioned, so many air compressor problems can be solved, or even prevented, if you’re working with a qualified compressed air professional. Kaishan USA works with a nationwide network of independent distributors, who can provide on-site help and consultation as needed. These factory-trained air compression experts are skilled in diagnosing and fixing air compressor problems.

Key Takeaways

-

- The compressed air industry has dealt with thousands of air compressor problems over the years.

- The top air compressor problem, a simple service alarm, usually doesn’t mean something’s wrong. But you can’t simply reset it and forget it.

- The primary reason your machine is over temperature is that it’s low on oil. But rather than simply adding oil, you should probably call your local service provider.

- If your compressor is not making air, you should start by confirming that your machine is actually running.

- Getting moisture in your compressed air is the best indicator that your compressor is oversized for your application.

Let Us Help

Preventing downtime and solving air compressor problems before they get out of control is critical to the operation of your compressed air system and all the processes that rely on that system. If you need help solving air compressor problems, get in touch with the experts at Kaishan. Contact us today.

Random stat or

customer quote

textXXtext

text