How Industrial Air Compressors Improve Laser Cutting Performance

January 3, 2024

Innovations: Portable Electric Air Compressors

January 10, 2024WHAT SIZE COMPRESSOR DO I NEED TO PAINT A CAR?

Kaishan USA | January 03, 2024 | Uncategorized

Air compressors use power, generated from a motor or engine, to compress air and deliver it in a pressurized flow to drive another operation or fulfill a task. In the automobile industry, air compressors are frequently used for painting cars, using compressed air to deliver paint through a nozzle in a strong yet even flow.

An air compressor for painting cars operates by breaking up paint with pressurized air, and using that pressure to produce a fine mist of paint through a nozzle. The air compressor for auto painting delivers air in a strong enough flow that the paint is turned into a fine, liquid particulate, which is ideal for an even coat over the vehicle.

In addition to a consistent flow, which ensures an efficient use of paint, using a compressor for auto painting is faster and easier than other painting methods. It enables full coverage, even in difficult-to-reach areas, without the need to manually check that paint covers every surface.

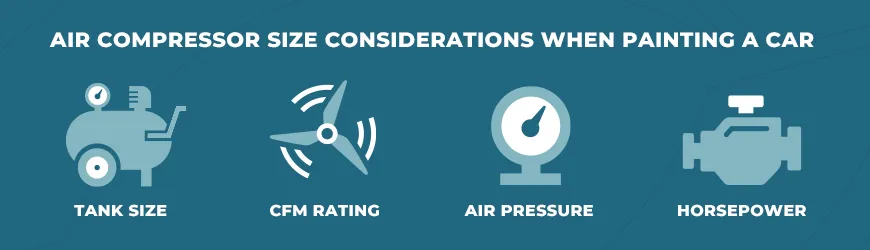

What Size Air Compressor Should Be Used To Paint A Car?

The answer depends on several factors. Based on the size of your operation and the types of auto painting you will need to complete, compressor criteria may differ. For example, full-vehicle painting will have more difficult requirements than a repair or touch-up job.

The list below will account for some of these more common applications:

- Tank Size: The tank size of an air compressor for spray painting cars makes a difference in the overall efficiency of the operation. Smaller tanks will need to be refilled, sometimes several times, in larger jobs such as full-vehicle coating. Smaller tanks may also introduce more variance in the pressure and flow of the paint, leading to uneven coats. Tank sizes of 50 gallons or more are typically recommended, while a tank size of 60 gallons or more will usually mean that an entire vehicle can be coated in one pass, without refilling.

- CFM Rating: A higher CFM is required to do the job of breaking up paint into the small particles that make spray painting the vehicle possible. A high volume of air will make the critical difference in making sure that paint is applied evenly and that the finished coat appears uniform. We will discuss PSI below, but a high-volume, low-pressure (HVLP) compressor is usually sufficient to complete an auto paint job. Look for 2-stage compressors that deliver close to 20 CFM.

- Air Pressure: As mentioned above, pressure (PSI) is less important in an air compressor for painting cars than CFM is. The pressure rating indicates at what pressure the paint is delivered from the nozzle, which is less important than obtaining a proper atomization of the paint through high CFM. Look for a minimum of 15 PSI, with some applications, such as clear coat, better-suited to 20 or 25 PSI.

- HP: For auto painting, a 10 HP compressor will typically suffice. However, higher HP compressors may operate more efficiently and can be used for other tasks.

Air Compressors From Kaishan USA

At Kaishan, we offer an extensive range of rotary screw air compressors with the qualities and features ideal for painting cars. Our product line includes the 2-stage compressors required to deliver sufficient CFM.

We also feature dryers and filters so that paint application remains uniform and attractive. In addition, our entire product line focuses on efficiency, value, and performance. This means you make a sound investment for any application. For more information, browse our air compressors today.

Random stat or

customer quote

textXXtext

text

In the auto industry, air compressors are frequently used for painting cars, using compressed air to deliver paint through a nozzle in a strong yet even flow.