Ultimate Guide to Rotary Screw Air Compressor System Design, Part One: 10 Important Questions To Get You Started

February 19, 2025

What Is a Motor-Driven Air Compressor, And How Does It Work?

March 5, 2025Everything You Need to Know About Air/Oil Separators

Kaishan USA | February 26, 2025| Uncategorized

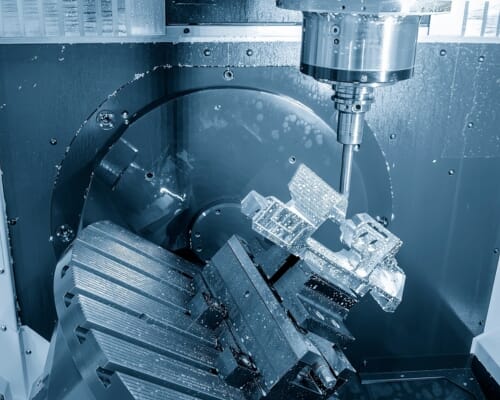

Most compressed air applications in industry can use oil-flooded compressors, which need air-oil separators to remove the oil mist from the air they are producing.

If you have an oil-flooded air compressor, you have an air-oil separator. And it’s a consumable. Knowing those two facts is good for your compressor, your company, your workforce and your health.

Here’s why: the original equipment manufacturer of your compressor specifies an air-oil separator according to the compressor model, the type of oil, the pressures you need and the ambient heat in your facility. Ignore those recommendations at your peril.

As we note in our blog post, “How to Maintain Your Air Compressor with Genuine Spare Parts,” inappropriate replacement of an air-oil separator can result in fires, explosions and even injuries to workers.

And while dramatic events like fires and explosions rarely happen, a problem with an air-oil separator can have many other negative consequences, including:

- Oil pass-through, resulting in poor air quality

- Pressure drop

- Increased cost

- Damage to downstream equipment

As a result, maintaining an air-oil separator is critical to the operation of an oil-flooded machine, such as Kaishan’s KRSP2 premium rotary screw air compressor.

Carefully maintaining its air-oil separator is critical to the operation of a rotary screw air compressor, such as Kaishan’s KRSP2 premium rotary screw air compressor.

Let’s look at this specialized component more closely.

What Is an Air-Oil Separator?

An air-oil separator is a specialized device featuring a mesh filter element located in a tank, also called a sump.

The combination of the swirling action in the tank with the filtration action of the element removes oil mist from the air leaving an oil-flooded screw compressor.

The swirling action in the air-oil separation tank, combined with the filtration action of the element, removes oil mist from the air leaving an oil-flooded screw compressor.

Why Does My Compressed Air Have Oil in It?

Any oil-flooded rotary screw air compressor has an oil lubrication system that performs the following functions:

- Seals the compression cycle

- Lubricates components

- Removes the heat of compression, lowering your system’s operating temperature

- Captures any contaminants in the air

Oil reduces friction and wear, controlling contamination and protecting your unit’s components from oxidation and corrosion.

Rotary compressor oil is so central to your compressor's operation that we consider it the lifeblood of your system.

But while that oil is critical to the operation of an oil-flooded rotary screw compressor, it causes problems if it gets into the downstream tools—everything from pneumatic handling systems to nail guns—that are powered by the compressed air.

As a result, the air-oil separator plays a critical role in removing that oil from the compressed air. Here’s how it works.

How An Air-Oil Separator Works

An air-oil separator has different systems to circulate the air and the oil. Let’s review each type of movement.

The Air Movement

After leaving the compression chamber, the air enters the separator tank or sump, which forces the air into a circular movement. That cyclonic effect forces out most of the oil.

The air then is drawn into the separator element, a mesh filter that removes all but a tiny fraction of the oil—3 parts per million, to be exact.

That’s clean enough for most industrial processes. But it’s not good enough if:

- Your products are ultimately consumed by humans, such as in the food, pharmaceutical or healthcare industries.

- You’re in the semiconductors or electronics industries, which require ultra-clean air.

- You apply coatings or finishes that even the tiniest oil droplets would mar.

In those situations, you may be able to get the air quality you need with additional filtration to remove oil or other particles in the air. Or you may want to go with an oil-free rotary screw air compressor, such as Kaishan’s KROF two-stage oil-free rotary screw air compressor. For more on deciding whether you need an oil-free compressor, see our blog post, “Ultimate Guide to Rotary Screw Air Compressor System Design, Part One: 10 Important Questions To Get You Started.”

The Oil Movement

The oil that falls to the bottom of the sump is drained by a scavenge line. It goes through a filter (to remove impurities) and a cooler (to remove heat), then back to the main oil tank to start the process over again.

Keeping your air-oil separator in good condition is essential for the performance of your rotary screw air compressor.

How to Maintain Your Air-Oil Separator

There are several key actions you need to take regularly to keep your air-oil separator operating correctly:

- Change the oil separator and lubricant every 4,000 hours if it’s a spin-on type, every 8,000 hours of operation (or annually) if it’s a standard drop-in type, or as indicated in your oil-sampling recommendations.

- Check the oil separator pressure differential alarm and replace it if the pressure drop through the separator is over 10 PSIG. Remember, a two-PSIG pressure drop caused by blocked filters will raise your energy consumption by an average of 1%.

And don’t forget to check the scavenge line! Clogged scavenge lines and orifices are the top cause of oil carry-over.

As mentioned, you’ll want to follow your manufacturer’s recommendations for any replacements you make.

Why Following Your Manufacturer’s Recommendation Is Good for Your Health

OEMs design their air-oil separators to fit tightly and ensure proper grounding on the inside. Unfortunately, many off-brand or pirated oil separators have a staple at the top. If that staple doesn’t make contact with the metal lid of the unit, it may not sufficiently ground the unit.

If a spark occurs in the sump, the tank could catch fire or even explode, potentially damaging equipment and causing severe injuries or death to nearby workers.

Kaishan adds a piece of copper on the top of the separator to enhance conductivity and reduce the risk of sparks, fires or explosions.

As mentioned, all manufacturers design air-oil separators to ensure a good fit, proper functioning and safe operation. That’s why we recommend following your manufacturer’s recommendations in using replacement parts and maintaining your compressor.

For more information on the benefits of using original OEM parts, check out our blog post, “How to Maintain Your Air Compressor with Genuine Spare Parts.”

Air-Oil Separator Troubleshooting

A few key findings point to specific issues with your air-oil separator:

- Oil carryover. If you’re getting oil in the air downstream, check the scavenge line and the filter element and clean if necessary. As mentioned, clogged scavenge lines and orifices are the top cause of oil carry-over.

- Contamination. Likewise, blocked filters and drains can cause dirt and other particles to linger in the air, decreasing quality and harming equipment.

- Pressure drop. A clogged separator will reduce air flow and increase energy consumption as your compressor struggles to produce the pressure and flow your system requires.

Technical Help Where and When You Need It

Diagnosing and correcting air-oil separator issues may require expert help. And replacing one of the larger separator elements can be a challenging job. That’s why we recommend you work with your local compressed air consultant.

We work with a nationwide network of independent distributors, who can provide on-site assistance and consultations as needed. These factory-trained air compression experts have experience with all aspects of compressed air systems and can service your compressor and your entire compressed air system.

Key Takeaways

- Any oil-flooded rotary screw air compressor has an oil lubrication system that seals the compression cycle, lubricates components, removes the heat of compression, lowers your system’s operating temperature and captures any contaminants in the air.

- Air-oil separators are critical in removing that oil from the compressed air.

- Maintaining an air-oil separator is critical to operating your air compressor and your compressed air system.

- We recommend that you closely follow your manufacturer’s recommendations in using replacement parts and maintaining your compressor.

Let Us Help

Maintaining the air-oil separator of your rotary screw air compressor is essential for the proper functioning of your compressed air system and all the tools and equipment that depend on it. If you need assistance with the operation and maintenance of your separator, reach out to the experts at Kaishan. Contact us today.

Listen to the Podcast Version

Understanding Air-Oil Separators

Hey, gang! Welcome back to the Big Dog podcast! We're so glad you could join us.So, let’s talk air-oil separators, Lisa. Essentially, this is a key component in oil-flooded air compressors. And what it does is pretty stunning—removing oil mist from compressed air by using a swirling action and, get this, mesh filtration. It’s how you make sure the air coming out is clean, effective, and, most importantly, safe.

Right, because without it, you’re not just dealing with poor air quality, but you're risking harming critical tools and equipment downstream. I mean, rotary screw air compressors rely heavily on these separators to keep their entire system running smoothly. But it’s not just about functionality—

Oh absolutely not. Some industries can’t afford even a trace of oil in their air. Food processing, semiconductor manufacturing, pharmaceutical production—any oil residue in those environments?

A disaster, right? Like, the equipment wouldn’t just be breaking down, but the end products could get contaminated too. It’s kinda shocking how small particles can be such a big problem.

Exactly. And here’s where the separator’s magic happens. Most of the oil? Spun out by the cyclone. Then, whatever tiny amount is left—literally three parts per million—gets caught in that mesh filter.

Three parts per million? That’s incredibly precise. But I’m guessing even that tiny bit could be trouble in, like, hospitals or electronics manufacturing.

You’re spot on. Those sectors sometimes need ultra-clean air, so they’ll go for extra filtration or even switch to oil-free compressors. But for most industries? That level of cleanliness with a functioning separator is more than enough.

And when it’s not functioning properly… well, then it’s not pretty. You’re looking at pressure drops, damaged equipment, unplanned downtime—it’s a domino effect from one small piece of equipment.

Which is why every maintenance manager worth their salt knows these separators are non-negotiable. I mean, the operational risks of ignoring them just aren’t worth it.

Maintenance Matters

Given how critical these separators are and the risks of neglecting them, let’s get into the nitty-gritty of maintenance. What exactly does it take to keep air-oil separators in top working condition?Well, first off, you’ve gotta, you’ve gotta change that separator regularly. Like clockwork. If it’s spin-on type, every 4,000 hours. Standard drop-ins? That’s more like 8,000 hours or annually. It’s non-negotiable, Lisa.

And skipping that? What happens?

Oh, where do I start? Poor air quality, rising operating costs, system failures—you’re essentially asking for trouble. Not to mention the pressure differential. If that exceeds 10 PSIG because, say, filters are clogged? You can kiss energy efficiency goodbye.

Wait, how much does that really impact efficiency?

A two-PSIG increase? That’s a one percent hike in energy consumption. Just from blocked filters!

Wow, that adds up if you’re running these compressors constantly. And I’m guessing scavenge lines play a big role in all this too?

Absolutely. Scavenge lines are like the unsung heroes here. Most oil carryover issues? It’s clogged lines or blocked orifices. And let’s be real, Lisa, if you leave that unchecked, you’ll end up replacing downstream equipment faster than you can say 'preventative maintenance.'

Right. I mean, the idea that something as small as a clogged line could snowball into an entire system shutdown is wild. Do you have an example where maintenance made all the difference?

Oh, I do. A shop I know was dealing with constant pressure drops and crazy energy bills. Turns out, they hadn’t addressed a clogged separator in months. Once they got it sorted? Pressure stabilized, downtime disappeared, and their energy use actually dropped—saved ‘em thousands annually.

Thousands, just from keeping up with maintenance? That’s huge.

Exactly. It’s why routine checks aren’t just “suggestions.” They’re the difference between smooth operations and total chaos.

The Human Element: Expertise and Safety

Jason, it’s clear from what you said earlier how much proper maintenance can save in the long run. But here’s something that struck me—what’s the real danger if we don’t stick to OEM specs for these separators? Like, what’s the worst that could happen?Alright, here’s the deal. Off-brand parts? They can be a total nightmare. Seen cases where separators weren’t grounded properly—something as small as a missed connection—boom, sparks in the sump. And, yep, you guessed it, fires, even explosions. Not exactly what you want during a regular workday.

Wait, explosions? That’s terrifying. And it’s all from just cutting corners?

Exactly. And look, it’s not just about avoiding catastrophic stuff. Using the wrong parts raises costs. You burn through more oil, increase pressure drops, risk more downtime. It’s this cascade of issues that could’ve been stopped by following the OEM specs.

Right, so it’s safer and more cost-efficient to just stick to what the manufacturers recommend. But let’s say you have a problem that’s not straightforward, like oil carryover or constant pressure drops. Would you say that’s when it’s time to bring in an expert?

Absolutely. That’s when you bring in someone trained—like, properly trained. It’s not just guesswork, Lisa. A lot of these issues aren’t what they seem. A clogged scavenge line could mimic major system failure if you’re not careful. Experts don’t just fix things; they spot problems before they blow up, literally or figuratively.

Right. And troubleshooting these systems isn’t exactly a DIY job, is it? Especially with newer separator tech coming into play.

Oh, for sure. Separator designs have come a long way. The focus now is on making them safer and more efficient. Copper grounding enhancements, integrated pressure alarms…it’s not about reinventing the wheel, but making it a whole lot sturdier. That’s why staying updated and working with a pro makes all the difference.

And that’s the balance, right? Newer tech solves old problems, but only if you’re using it correctly and maintaining it well. It’s reassuring to know there’s expertise out there when things get tricky.

Exactly. And look, the bottom line is this—these systems don't run themselves. Whether it’s sticking to OEM specs, watching for tell-tale signs like pressure drops, or knowing when to call in heavy hitters, the human element is what keeps everything running smoothly. And safely.

And that’s a wrap, folks. Thanks for tuning into The Big Dog Podcast, where safety and performance always come first. Keep your systems running clean, and we’ll see you next time.

Random stat or

customer quote

textXXtext

text