How the Right Air Compressor Enables the Soft Touch that Makes Pneumatics So Valuable

June 11, 2025

Adams Direct & Media Services

June 20, 2025How to Deliver the Compressed Air Quality Your End Users Need

Kaishan USA | June 18, 2025 | Uncategorized

Medical equipment must be manufactured under sterile conditions using clean, dry compressed air to maintain patient safety during invasive medical procedures.

Air quality is a critical concern for compressed air systems, with applications such as food and beverage, electronics, and medical devices.

And it’s not just oil-free. Applications such as painting and electronics need dry air, free of moisture. And particles are a definite no-no for healthcare uses.

There are even applications like automotive painting (For more information, see our blog post, “Quality is Job One in Automotive Air Compressors”) requiring an even, pulse-free flow of air.

Car manufacturers need steady flows of clean, dry compressed air to deliver the mirror finishes that car buyers demand.

The process of ensuring high-quality compressed air starts even before the air enters your compressor.

GIGO: What Goes in and What Goes Out

When programmers first started using the phrase “garbage in, garbage out” in the 1960s, they were only discovering what compressed air professionals had known for decades: the quality of the output is heavily dependent on the input.

Here’s why: when the air you’re drawing into your compressor is filled with moisture, diesel oil, fumes and dust, all those contaminants become more concentrated as the air moves through the compression process, according to Parker Hannifin’s Industrial Gas Filtration and Generation Division. And your compressed air system must do double duty to remove them. Sometimes, even the best systems can be overwhelmed.

Bringing clean ambient air into your compressor is the best, most cost-effective way to deliver clean compressed air.

Unfortunately, many industrial environments aren’t clean air environments. Cement plants are a prime example, with cement dust joining with airborne moisture to create a compressor’s worst nightmare: a super-muck that can clog compressor internals.

The airborne dust and dirt in cement plants are challenging for air compressors.

Metal-working plants with welding gases in the air are another environment that will need special attention. And hot, arid settings present different challenges, adding dust and dirt to the air.

There are a couple of ways to cope with these types of environments:

- Filtration. Placing good filters in front of the inlet air valve will help eliminate many problems. Unfortunately, the worse the environment, the more maintenance those filters require. In a bad environment, they can get clogged quickly. In worst-case scenarios, they can get blocked entirely, creating a vacuum that starves your compressor of air and results in significant damage.

- Remote air intake. If your ambient air contains airborne contaminants such as welding gases, you can bring clean air in from the outside. Avoid putting an air duct to the loading dock, however. That’s just adding another contaminant.

A second aspect of compressed air quality is your choice of compressors.

Air Compressor Choices

All kinds of air compressors are used today, including the primary industrial types—reciprocating, rotary screw and centrifugal air compressors. It’s not unusual for a large plant to have all three types deployed in various applications.

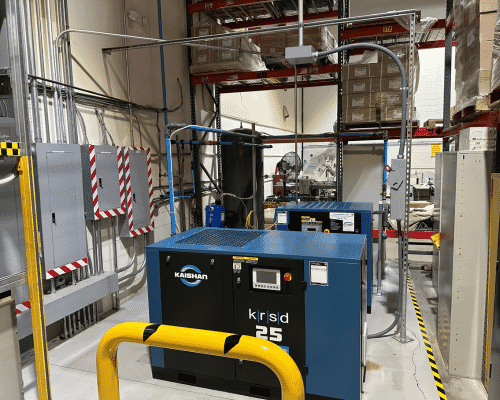

Reciprocating compressors are usually preferred for small, isolated uses. Meanwhile, rotary screw air compressors handle a wide range of tasks, such as hand tools, material handling and pneumatics.

However, applications needing the highest levels of compressed air quality usually turn to centrifugal or oil-free rotary screw compressors. We’ll talk about centrifugals first.

The Advantages of Centrifugal Compressors

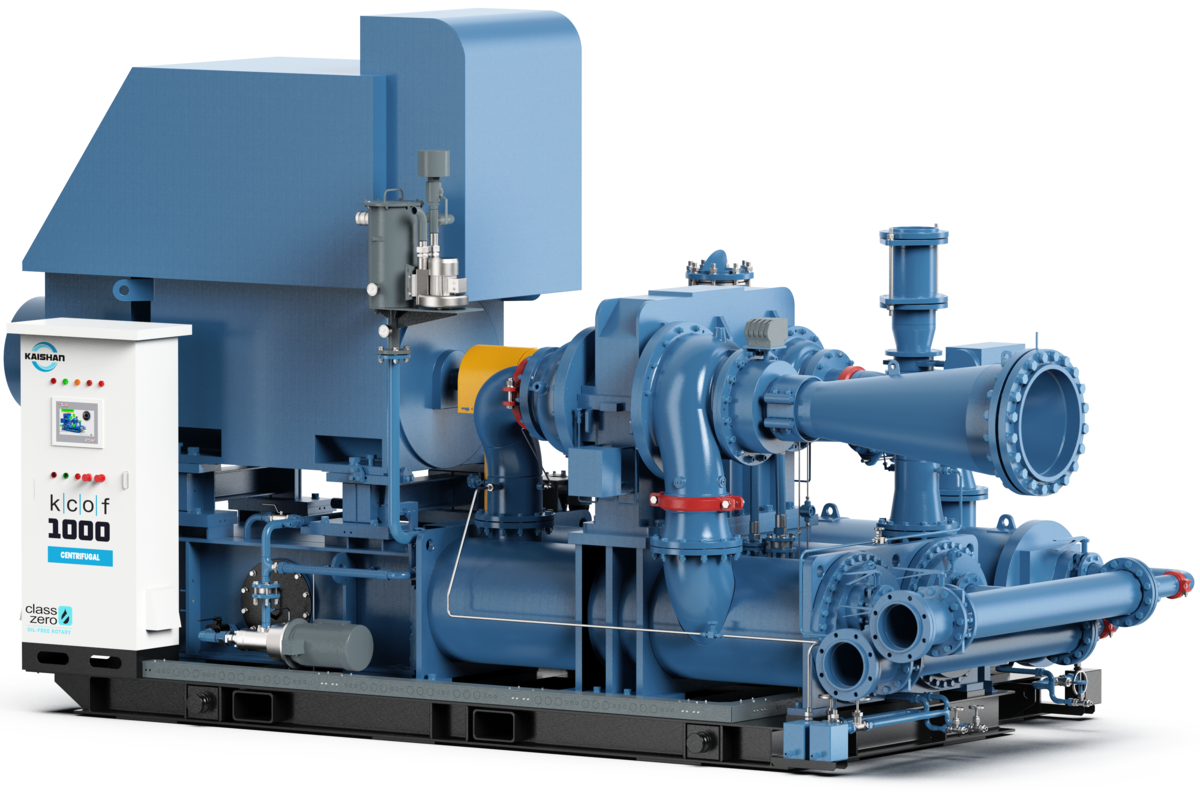

Centrifugal compressors are most efficient at compressor sizes above 500 HP: the larger the demand, the more efficient centrifugals become. Unlike other types of compressors, centrifugals do not introduce oil mist into their compression chambers. They are oil-free by design.

Centrifugal compressors offer additional advantages, including precise control, long lifespan and low maintenance. One of the most attractive options on the market is Kaishan’s KCOF.

KCOF: Taking Service to a New Level

Kaishan’s KCOF centrifugal air compressor offers OEMs an exciting option for oil-free compressed air.

Kaishan’s KCOF centrifugal compressor ranges from 250 HP and 1,400 CFM to over 10,000 HP and 50,000 CFM. Pressures can vary from 35 PSIG-320 PSIG.

Specific benefits include:

- Advanced control capabilities. All our KCOF centrifugals have a field-proven control and energy management software solution. Kaishan offers a user-friendly open architecture that uses industry-standard Allen-Bradley PLC hardware.

- Easier maintenance. The KCOF offers a self-cleaning inlet air filter as an option, reducing the need for filter change-outs in very dirty environments. It also features a split gearbox, enabling extensive service to be performed on-site by a qualified technician. Split bearings allow minimal downtime and ease of maintenance, keeping service hours and rates low. It also has longer service intervals.

- Unmatched parts delivery. No one delivers the parts you need as quickly. As one of the world’s few fully integrated manufacturers of centrifugal compressors, we have the parts you need when you need them. No one can match our parts availability.

For applications that do not need the large scale of a centrifugal compressor, however, Kaishan offers another oil-free choice.

Kaishan KROF: Changing the Oil-Free Game

KROF two-stage oil-free rotary screw air compressor is another oil-free option.

It produces ISO 8573-1, Class 0 oil-free compressed air that safeguards the integrity of your products and sets new standards for reliability, efficiency and warranty protection.

The KROF exemplifies cutting-edge engineering and is available in 100-, 125- and 150-PSIG models. It’s the best choice for demanding oil-free applications because of its robust features:

- Two intermeshing PTFE-coated rotors machined to micron precision from bar stock in our Loxley, AL plant.

- Oversized stainless-steel precoolers on each stage that lower temperatures for both intercoolers and aftercoolers.

- Advanced bearings that eliminate the need for an outdated balance piston and require no maintenance to achieve proper thrust loading.

- Oversized moisture separators equipped with reliable, zero-loss drains that prevent moisture from passing between stages and handle contamination better than traditional orifice-style drains.

- Our exclusive Ultra-Web® air filters remove small particles, preventing your compressor from ingesting dirt and wear particles that could compromise the environment and shorten the life of your compressor.

Kaishan’s new KROF two-stage oil-free compressor is an excellent choice for uncontaminated, highly efficient and reliable air.

However, even with oil-free compressors, you may need to take additional precautions.

Additional Steps May Be Needed

While both centrifugal and oil-free rotary screw air compressors do not add oil in the compression cycle, there may be oil and other contaminants in the incoming air, as mentioned previously. So those impurities have to be removed. Let’s look at our cleanup choices.

Batting Cleanup: Improving Air Quality After It’s Compressed

The main tactic for cleaning up compressed air is using filters at various stages of the process.

You can get different grades of compressed air filters to match the requirements of your application, removing solid particles, liquid water, water and oil vapors, odorants and even bacteria and viruses.

Filtration options include the following:

- Particulate filters. Eliminating the dust, dirt and other contaminants.

- Coalescing filters. Pre-filters designed to handle oil vapors and mists.

- Mist eliminators. A more heavy-duty coalescing pre-filter to handle slugs.

- Activated carbon filters. Similar to a charcoal filter, located after the dryer to eliminate any remaining hydrocarbons (think diesel exhaust in the ambient air) that would keep you from reaching the desired level of filtration.

These filtration methods are even good enough to enable an oil-lubricated rotary screw compressor to provide air clean enough for many sensitive applications.

Another Choice: Oil-Flooded Compressors

If you are in applications less sensitive to oil mist, you may achieve significant savings with an oil-flooded rotary screw air compressor that can service a variety of other applications, such as air tools, grinders, impact wrenches, pneumatic equipment and material handling. Oil-lubricated compressors typically have lower lifetime costs than oil-free machines because they have lower acquisition, maintenance and electricity costs.

They offer several significant advantages:

- Performance advantages. Oil-lubricated rotary screw air compressors enable you to run equipment and tools with high horsepower requirements. Plus, they are based on a simple, time-tested design that enables impressive efficiency. They can handle a 100% duty cycle; as a result, we recommend setting up your compressed air system so that they operate as close to full load as possible. Rotary screw compressors provide a steady flow of clean, high-quality air without the pulsations that can occur with other types of compressors, particularly reciprocating or piston compressors.

- Operational advantages. Rotary screw air compressors are highly reliable and require less maintenance. They can handle variations in demand and temperature extremes and are relatively safe. They have a compact footprint and generate less noise.

- Lifetime cost advantages. Rotary screw air compressors are known for their dependable operation, which means that you will have less downtime. They have a long lifespan and a relatively low total cost of ownership. Plus, they have better warranties than other types of air compressors due to their reliability, efficiency and long life.

Our rotary screw air compressors achieve oil levels of 3 PPM and can be equipped with filtration mentioned previously, reducing oil levels even lower. Perhaps not good enough for food or semiconductor applications. But it is acceptable for a wide range of uses.

For more on the pros and cons of different compressor types, read our blog post, “Which Type of Air Compressor Is Best for Your Application?”

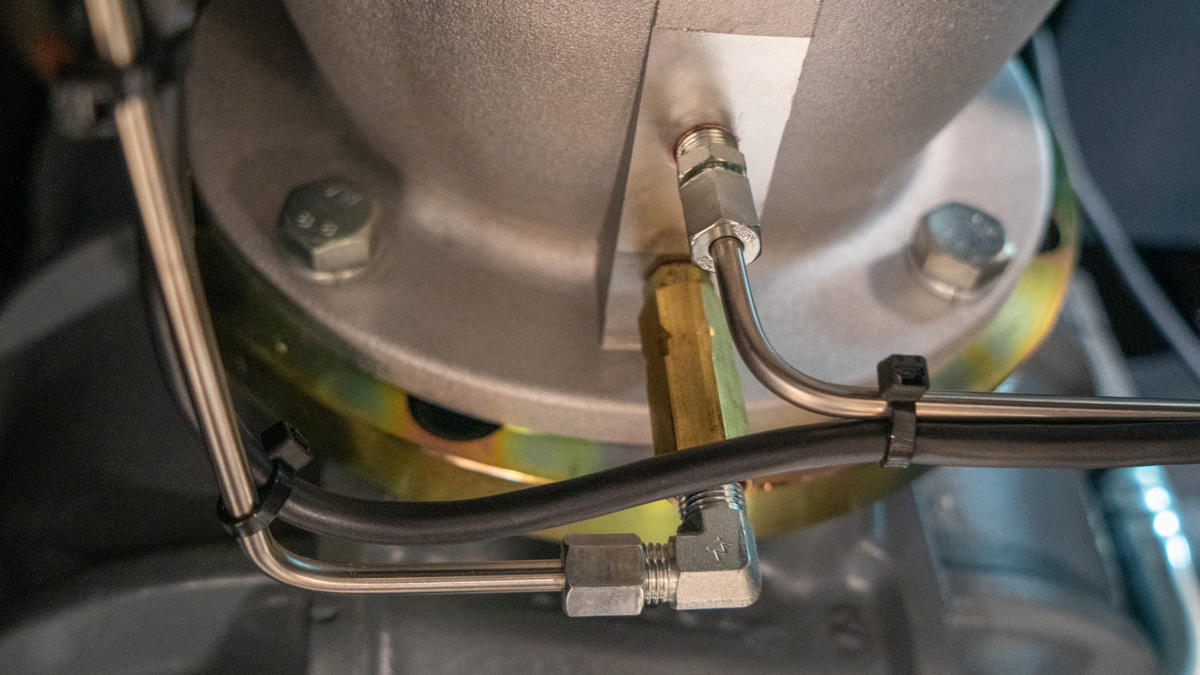

Stainless-Steel Fittings

Another step that enables Kaishan compressors to uniquely provide clean, dry air is our use of stainless-steel fittings, which resist corrosion. While some competitors use carbon steel and carbon steel with copper cladding, we use stainless steel to make it less likely that they will deteriorate internally and send particles downstream, potentially clogging over time.

We use stainless steel fittings, which are less likely to deteriorate with age and send flakes of dirt and rust downstream.

Maintenance Is Critical

The critical consideration for filters is maintenance. Clogged filters will impede and eventually block airflow, causing energy loss that is both unnecessary and avoidable. So you’ll need to replace filter elements regularly.

How often? It depends on the quality of the supply air and how many hours you operate your system. One approach is to replace the filter elements every few months. A better choice is to install differential pressure sensors, which will detect any pressure change between a filter's supply and output pressures. For example, a pressure drop would indicate that the filter is becoming clogged and needs to be replaced. You can monitor that information remotely through AirWatch, our Internet of Things connection.

We recommend the following replacement schedule:

- Oil filters every 2,000 hours

- Air filters at 4,000 hours

- Air/oil separators at 8,000 hours

Note that these service intervals are for ideal conditions. If you have any issues with your incoming air, like welding gases, dust or dirt, you are strongly advised to do these routine items more frequently.

The bottom line? Your compressed air quality will only be as good as your maintenance. The best way to tell if you need more frequent maintenance is to draw an oil sample.

Oil Sampling

Fluid sampling is critical to the life of an oil-flooded rotary screw air compressor. Regularly sampling oil will tell you whether it is being exposed to excessive heat or taking in contaminants. It can also detect excessive bearing wear, allowing you to be proactive when you uncover a problem, even avoiding an unplanned shutdown.

That’s why we consider oil sampling the most critical maintenance procedure for our compressors. We also require that our customers collect an oil sample and have it analyzed every 2,000 hours or every 1,000 hours for food-grade applications to maintain their warranty protection.

The best approach is to set up a comprehensive maintenance program, with the help of your compressed air professional.

The Key to Air Quality? Your Local Compressed Air Pro

If you need to improve the compressed air quality you provide, the best place to start is with your local compressed air system consultant. We have established a nationwide network of independent distributors, who can provide the on-site air quality help and consultation you need.

We partner with independent, local distributors because there’s no better way to provide expert guidance, fast response times and advanced support tailored to your needs. They don't just sell compressors—they build partnerships, ensuring you get the right system, reliable service and quick access to parts when you need them most.

They have factory-trained technicians and a deep understanding of industrial applications, helping you maximize efficiency and minimize downtime. So, when you buy through Kaishan, you're getting more than a product—you're getting a local partner who cares about your business and wants to see it succeed.

Key Takeaways

- Air quality is a critical concern for compressed air systems, with applications such as food and beverage, electronics, painting and medical devices.

- Compressed air professionals have known for decades that the quality of the output is heavily dependent on the input.

- Applications needing high levels of compressed air quality usually turn to centrifugal or oil-free rotary screw compressors.

- Centrifugal compressors are most efficient at compressor sizes above 600 HP.

- For applications that do not need the large scale of a centrifugal compressor, Kaishan offers another oil-free choice, the KROF two-stage oil-free rotary screw air compressor.

- However, even with oil-free compressors, you may need to take additional precautions.

- If you are in applications less sensitive to oil mist, you may achieve significant savings with an oil-flooded rotary screw air compressor.

- The bottom line: your compressed air quality will only be as good as your maintenance.

Let Us Help

Providing compressed air quality that meets the requirements of your end-use application is critical to the success of your entire operation. If you need help providing the compressed air quality your operation requires, get in touch with the experts at Kaishan. Contact us today.

Listen to the Podcast Version

Why Air Quality Matters

Alright, welcome back to The Big Dog Podcast. I’m Jason Reed, and as always, I’m here with Lisa Saunders. Today, we’re talking about something that, honestly, gets overlooked way too often—air quality. Not just any air, but the air going into your compressor. Lisa, you ever walk into a plant and just know, like, the air’s not right?Oh, absolutely. And it’s wild how many industries depend on this. I mean, food and beverage, electronics, medical devices, automotive—if you mess up the air, you mess up the whole process. It’s not just about keeping the machines happy, it’s about keeping the end product safe and up to spec. Like, you don’t want a little dust particle in your IV bag, right?

Yeah, or a little oil mist in your chocolate bar. That’s a bad day for everyone. And it’s not just about oil, either. Some applications, like painting cars or making circuit boards, they need air that’s dry, no moisture, no particles, nothing. I always say, “garbage in, garbage out.” If you start with dirty air, you’re gonna end up with dirty output, no matter how fancy your compressor is.

That’s the GIGO principle, right? Programmers came up with it, but honestly, compressed air folks have been living it for decades. If your intake air is full of moisture, diesel fumes, dust—whatever—it all gets concentrated as you compress it. And then your system’s gotta work overtime to clean it up, if it even can.

Exactly. I’ve seen it firsthand. There was this paint shop—won’t name names, but they had a massive recall. Turns out, their intake filters were clogged, and nobody noticed. So all this dust and junk got into the compressed air, and it ended up in the paint. Cars coming off the line with these little specks in the finish. Whole batch had to be redone. That’s thousands, maybe millions, down the drain just because someone skipped a filter check.

Ouch. And it’s not just paint. In medical manufacturing, if you don’t have clean, dry air, you’re risking patient safety. Same with food—one slip, and you’re looking at a recall or worse. So, yeah, air quality isn’t just a box to check. It’s the foundation for everything downstream.

And the crazy part is, the best way to get clean compressed air is to start with clean ambient air. But, let’s be real, most plants aren’t exactly pristine environments. Cement dust, welding fumes, you name it. That’s where things get tricky.

Fighting Contaminants on the Shop Floor

Let’s dig into that. So, what are we actually fighting against? You’ve got moisture, oil, dust, fumes—each one comes from somewhere different. Moisture’s in the air, oil can come from the compressor itself, dust is everywhere, and fumes—well, if you’ve got welding or forklifts running diesel, you know the deal.Yeah, and in some places, like cement plants, you get this nasty combo of dust and moisture. It turns into this, uh, super-muck that just clogs everything up. I mean, you can put filters on your inlet, but in a bad environment, those filters get clogged fast. If you don’t keep up with maintenance, you’re basically starving your compressor for air, and that’s a recipe for a breakdown.

And sometimes, filters aren’t enough. That’s where remote air intakes come in. You can pull air from outside the building, where it’s hopefully cleaner. Just don’t run the duct to the loading dock—unless you want to suck in diesel fumes and who knows what else. But even with all that, if you don’t change your filters, you’re in trouble. I saw this at a metalworking plant—maintenance skipped a couple filter changes, and it cost them thousands in repairs. The filters were so clogged, the compressor was working overtime, and eventually, it just gave up. Total shutdown.

Yeah, and it’s not just about swapping filters on a schedule. The best way is to use differential pressure sensors. They’ll tell you when a filter’s getting clogged, so you can change it before it becomes a problem. And, honestly, if you’re running in a dirty environment, you gotta check those way more often than the manual says. Otherwise, you’re just asking for trouble.

And don’t forget about oil sampling. Especially with oil-flooded rotary screw compressors, regular oil analysis can catch problems before they turn into a shutdown. It’s like, the cheapest insurance you can buy for your system. And for food-grade or medical, you might need to do it even more often to keep your warranty.

Right. And, you know, even with all the best filters and sensors, you still need to have a solid maintenance plan. That’s what separates the plants that run smooth from the ones that are always putting out fires. It’s not glamorous, but it’s what keeps the lights on.

Choosing and Maintaining the Right Compressor

So, let’s talk about picking the right compressor. There’s a lot of options—reciprocating, rotary screw, centrifugal. Each one’s got its place. Reciprocating is usually for small, isolated jobs. Rotary screw is the workhorse—good for tools, material handling, all that. But if you need super clean air, like for food, electronics, or medical, you’re probably looking at oil-free rotary screw or centrifugal.Yeah, and centrifugal compressors really shine when you’re talking big horsepower—like, above 500 or 600 HP. They’re oil-free by design, so you don’t have to worry about oil mist getting into your product. Kaishan’s KCOF is a good example. It’s got advanced controls, self-cleaning inlet filters, split gearboxes for easy maintenance, and, honestly, the parts availability is top notch. If you need a lot of clean air, that’s the way to go.

But if you don’t need that much capacity, Kaishan’s KROF two-stage oil-free rotary screw is a solid choice. It’s got these PTFE-coated rotors, oversized stainless-steel precoolers, and their Ultra-Web filters that catch even the tiniest particles. Plus, the moisture separators with zero-loss drains are a game changer for keeping water out of your air.

And, you know, even with oil-free compressors, you still gotta watch what’s coming in. If your intake air is dirty, you’re still gonna have problems. That’s why filtration and regular maintenance are so important. And for less sensitive applications, oil-flooded rotary screw compressors can save you money—they’re reliable, efficient, and with the right filters, you can get the oil content down pretty low. Maybe not for food or semiconductors, but good enough for a lot of shops.

And don’t forget the little things, like using stainless-steel fittings instead of carbon steel. It sounds minor, but it keeps rust and flakes out of your system. Kaishan does that across the board, and it really helps with long-term reliability.

Bottom line—your air quality is only as good as your maintenance. You gotta have a plan: change filters, sample oil, monitor pressure drops. And honestly, don’t be afraid to call in a local compressed air pro. They know the ins and outs, and they’ll help you set up a system that actually works for your plant, not just what looks good on paper.

Yeah, and if you’re not sure where

Random stat or

customer quote

textXXtext

text