All the Ways Heat Gets into Your Compressed Air System (And How To Get Rid of It)

October 16, 2024

Signs Your Air Compressor Needs Repair or Replacement

October 30, 2024Five Money-Saving Ways to Extend the Lifespan of Your Air Compressor

Kaishan USA | October 23, 2024| Uncategorized

Because the air reaches temperatures of up to 350°F during the compression cycle, removing heat and ensuring a long lifespan is challenging for oil-free air compressors such as those used in the electronics industry.

Air compressors represent a significant capital outlay for most companies. Unfortunately, however, too many companies adopt a set-it-and-forget-it attitude, failing to take the steps necessary to realize the value and potential of their investment.

And that’s a shame because a properly maintained rotary screw air compressor can be a productive asset for years, even decades.

What follows are five key steps you can take to ensure your compressor has a long life. And all will save you money in the short as well as the long term. We’ll start with fluid selection.

1. Selecting the Right Lubricants

Any oil-flooded rotary screw air compressor has an oil lubrication system that seals the compression cycle, lubricates components and removes the heat of compression, lowering your system’s operating temperature. It’s so central to the operation of your compressor that we consider rotary compressor oil the lifeblood of your system. And it’s why we place so much importance on selecting the right oil for our compressors.

Kaishan worked with an expert global developer of industrial lubricants to formulate the rotary compressor oil we install in our compressors. Our KTL-8000 rotary compressor oil is a hydrologically stable synthetic with ester chemistry additives. We strongly encourage every customer to use it in their Kaishan machines. We also offer a PG (polyglycol) alternative for high-humidity conditions. For specifications, see the data sheets for our lubricants.

KTL-8000 rotary compressor oil is a hydrologically stable synthetic lubricant that lasts two times longer than mineral-oil-based products. See the data sheets for our lubricants.

KTL-8000 lasts two times longer than mineral-oil-based products, saving you money by using less oil, reducing labor costs and cutting oily waste.

While it’s true that oil-free units do not rely as much on oil, they still use oil to lubricate bearings and gears external to the compression cycle and lower the operating temperatures in the stage cooling jackets (keeping casting temperatures lower).

For more information on our lubricants, read our blog post, “Choosing the Right Rotary Compressor Oil.”

Using Food Grade Lubricants

It’s always a best practice to follow U.S. FDA regulations and use food-grade oils in your oil-lubricated air compressors in areas like packaging with incidental food contact. But remember, you will need to change the oil more often. Most manufacturers recommend changing food-grade lubricants at 4,000 hours (compared to 8,000-hour intervals for regular oils).

Because oil plays such an essential role in the life of your compressor, we recommend regular oil sampling.

2. Sample Oil Regularly

Fluid sampling is crucial in extending the life of an oil-flooded rotary screw compressor. Regular oil sampling will tell you whether your lubricant has been exposed to excessive heat or taking in contaminants. It can also detect excessive bearing wear, allowing you to be proactive when you uncover a problem, perhaps even avoiding an unplanned shutdown.

We recommend sampling oil every 2,000 hours for regular lubricants and every 1,000 hours for food-grade lubricants.

That’s why we consider oil sampling the most critical air compressor maintenance procedure. We recommend sampling oil every 2,000 hours for regular lubricants and every 1,000 hours for food-grade lubricants. And we require oil sampling to maintain warranty coverage.

For more on oil sampling, read our blog post, “Choosing the Right Rotary Compressor Oil."

As mentioned, oil helps keep temperatures under control, another critical step in ensuring compressor longevity.

3. Keep Compressor Temperature in the Proper Range

The ambient air that entered your system at 70°F will reach 175°F-200°F in an oil-lubricated screw compressor, according to Air Compressor Guide. Keeping your unit within that range will ensure your compressor’s long-term health.

As mentioned, oil-free units do not use oil as a cooling agent (although gear oil floods the jackets in the airend to help cool the discharge air and keep the housing temperatures lower). The goal, of course, is to ensure clean, pure air for sensitive applications like food and beverage, healthcare, medical, electronics and semiconductor applications.

But that makes airend cooling even more of a challenge for oil-free units. The ambient air that enters your system at 70°F? It will reach 350°F in an oil-free rotary screw air compressor. As a result, Kaishan goes the extra mile, equipping its KROF two-stage oil-free rotary screw air compressor with oversized coolers and high-temperature, stainless-steel pre-coolers.

To ensure proper heat removal, Kaishan’s KROF oil-free rotary-screw air compressor has oversized coolers and high-temperature, stainless-steel pre-coolers.

For more on temperature control, read our blog post, “All the Ways Heat Gets into Your Compressed Air System (And How To Get It Out).”

Another critical consideration in keeping your system cool is ensuring it has proper air flow.

4. Make Sure Your Compressor Has Good Air Flow

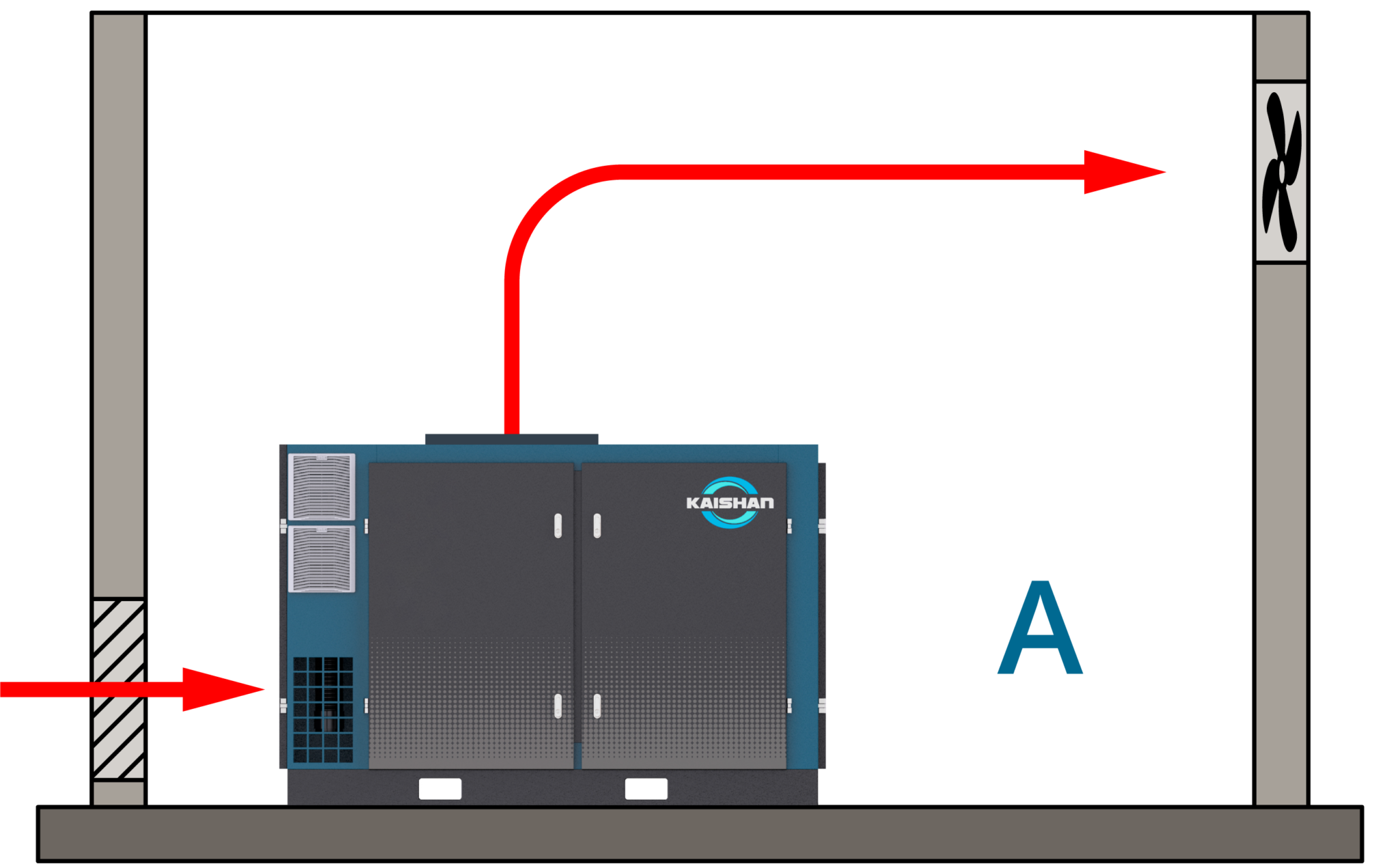

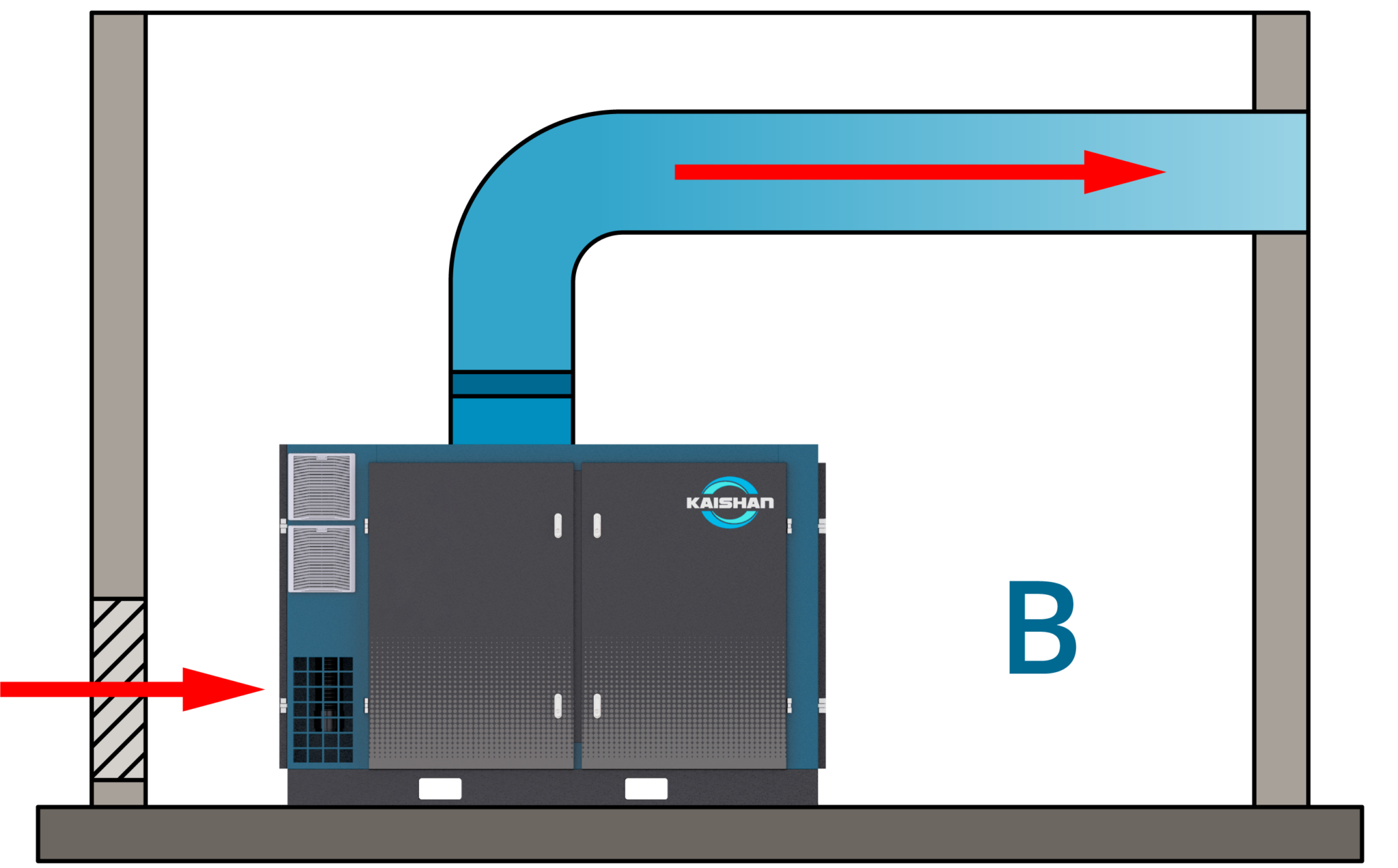

We recently saw an installation where a compressor was in a large room but isolated at one end. So there was plenty of inlet air, but no exhaust to remove heat. The air compressor recycled the hot air, causing the compressor to become stagnant and overheat. As a result, the facilities team was unable to keep the machine running. We advised them to install a duct to remove the hot air, and the compressor began running smoothly within ten minutes.

The critical point is that whether you’re talking about the clean air that is pulled into your compressor or the air flow needed to remove the heat of compression from your heat exchangers, your compressor uses massive amounts of air. Compressors alone produce 17,522 BTU/hour for every 1 HP. And don’t forget to include compressed air dryers in your calculations of ventilation requirements.

As a result, ventilation is one of the most critical considerations for the operation and longevity of your compressed air equipment. The goal is to remove all that heat generated during compression and keep it from recirculating back into the room.

You can use several possible configurations to move air through your equipment room.

- Louvered vents. For smaller compressors, louvered inlets and outlets in your compressor room may provide enough air flow through your enclosure to remove the heat generated in the compressor. But it all depends on the ambient conditions. Consult a qualified heating and air conditioning professional in your area for sizing, design and installation of ductwork.

Depending on ambient conditions, you may only need louvered inlets and outlets to cool a smaller compressor.

- Forced ventilation. Compressors larger than 25 HP usually require forced ventilation, but every site is different. An exhaust fan pulls the air through the ductwork and blows it outside. Unfortunately, it’s not as simple as it looks, especially in small enclosures with low ceilings. If you add bends and curves to reach the outlet, you build up back pressure in the ducts—a 90° turn, for example, is like adding 30 feet of straight ductwork. So just adding a few zigs and zags creates a lot of resistance, resulting in heat building inside the compressor.

For larger units (25 HP and above), you probably will need a fan (not shown) and ductwork to remove heat.

- Water cooling. Water can also be substituted as a cooling medium instead of air. In a water-cooled compressor, a pump moves water through tubing around the compressor body, extracting the heat. The water then goes to a radiator, usually a shell and tube heat exchanger, to cool. Water cooling is more common in larger units (more than 300 HP).

Another aspect of ventilation is air compressor maintenance, ensuring that your compressor, intake air vents, louvers and filters are clear. That’s especially important in dusty, dirty environments.

5. Maintain Your Compressor

Ensuring the longevity of your compressed air system requires an ongoing air compressor maintenance effort.

Every day before startup, you should:

- Check the oil level using the sight glass before starting your compressor; add oil if the level has dropped.

- Remove any scale, rust, dirt or other solids from condensate traps and drain points.

- Make sure drains are not stuck either in an open or closed position.

- Listen for air leaks. For more on leaks, see our blog post, “How to Find and Stop Air Leaks.”

- Check for excessive vibration or strange bearing noises. For more warning signs of compressor failure, see our blog post, “What Is the Most Common Cause of Air Compressor Failure?”

- Make sure all electrical and mechanical connections are secure.

- Pay attention to warnings from your compressor controls.

- Ensure heat exchangers are clean and flowing freely.

- Ensure any enclosure filters are clean and free flowing.

In addition, you’ll want to perform routine oil changes and ensure your cooling system is working properly.

For more on air compressor maintenance, read our blog post, “Ten Need-to-Know Rotary Screw Air Compressor Maintenance Tips.” Or for an air compressor maintenance checklist, download our white paper, “Air Compressor Maintenance: Ultimate Guide and Checklist”.

Local Help in Establishing an Air Compressor Maintenance Program

Selecting the right oil, drawing samples regularly, keeping the temperature in the correct range, ensuring good air flow to your compressor and appropriate air compressor maintenance are key steps in ensuring the life of a rotary screw air compressor. If you are not confident in your ability to take these steps, you should strongly seek the help of a local compressed air professional.

We work with a nationwide network of independent distributors, who can help you implement any of these steps to ensure the life of your compressor. They can also service your air compressor system without a problem. And help you select the right compressor for your application.

Key Takeaways

- Use the recommended lubricants.

- Sample oil every 2,000 hours or 1,000 hours for food-grade lubricant.

- Keep compressor temperature in the proper range.

- Make sure your compressor has good air flow.

- Maintain your compressor.

Let Us Help

Extending the lifespan of your rotary screw air compressor is critical to the long-term success of your compressed air system and all the processes that rely on that system. If you need help taking any of the steps mentioned above, get in touch with the experts at Kaishan. Contact us today.

Random stat or

customer quote

textXXtext

text