The Key to Air Compressor Longevity: Getting Your Bearings

July 9, 2025

Six Low-Cost Fixes for Compressed Air Optimization in Times of Economic Uncertainty

July 23, 2025Preserve Your Compressor’s Design Integrity by Using OEM Parts

Kaishan USA | July 16, 2025 | Uncategorized

Using quality OEM replacement air compressor parts is critical to the performance of your compressor and all the end uses it supports.

You’ve probably heard the many reasons why you should only use OEM air compressor parts to maintain your air compressor. You’ll get better performance, save energy, enjoy greater reliability and longer life, to name just a few. We explain those benefits in great detail in our blog post, “How to Maintain Your Air Compressor with Genuine Spare Parts.”

But there is a larger, global issue that is perhaps more serious than any of these concerns. And that is design integrity.

The Larger Issue: Design Integrity

When you’re not using parts from the original equipment manufacturer, you’re going off the reservation, straying from the intent of the engineer who designed your compressor.

Each of those air compressor parts was specified and manufactured to achieve specific design goals. And substituting an off-brand or pirated component to save money compromises your compressor’s design integrity.

You’re subverting the design, and the most likely result is that you’ll be putting additional stress on your machine. And that can have negative consequences. It's no wonder that most manufacturers will void your warranty for using off-brand parts.

An ordinary filter is a good example. If an aftermarket doesn’t capture all the dust and particles that the OEM filter would screen out, those particles will most likely migrate downstream. And, on the other hand, if it over-filters, you could suffocate the inlet.

This post will review a few compressor components or consumables that illustrate how deviating from the design engineer’s original intent is not the most effective way to save money. We’ll start with the air-oil separator.

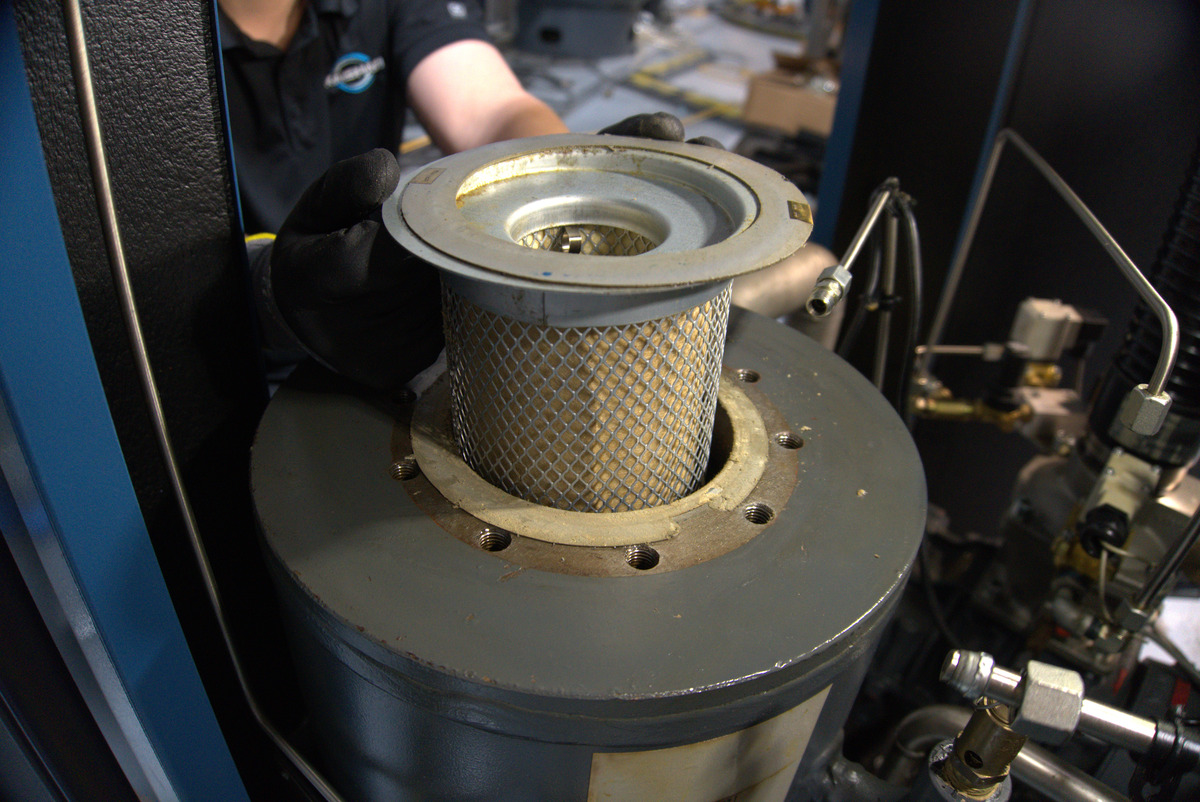

The Air-Oil Separator

The air-oil separator is one of the most critical replacement parts in a rotary screw air compressor.

Inappropriate replacement of an air-oil separator can result in fires, explosions and even injuries to workers. Here’s why: OEMs design their air-oil separators to fit tightly and ensure proper grounding on the inside. Unfortunately, many off-brand or pirated oil separators have a staple at the top. If that staple doesn’t make contact with the metal lid of the unit, it may not sufficiently ground the unit.

Air-oil separators are one of the most critical replacement parts in a rotary screw air compressor and replacing one with an off-brand part can result in fires, explosions and even injuries to workers.

If a spark occurs in the sump, the tank could catch fire or even explode, potentially damaging equipment and causing severe injuries or death to nearby workers. Kaishan adds a piece of copper on the top of the separator to enhance conductivity and reduce the risk of sparks, fires or explosions.

And while dramatic events like fires and explosions rarely happen, a problem with an air-oil separator can have many other negative consequences, including:

- Oil pass-through, resulting in poor air quality

- Pressure drop

- Increased cost

- Damage to downstream equipment

That’s why we recommend following your manufacturer’s recommendations in using replacement air compressor parts and maintaining your compressor. For more on the air-oil separator, read our post, “Everything You Need to Know About Air/Oil Separators.”

Next is air compressor oil.

Air Compressor Oil

If you’re looking for a less expensive alternative to your OEM’s recommended air compressor oil, it’s probably not too hard to match the viscosity. But, once again, that misses the designer’s intent. The real magic in OEM-branded oil is in the additives that enable heat rejection and ensure proper oil flow throughout the machine.

Kaishan USA collaborated with a global expert developer of industrial lubricants to formulate the rotary air compressor oil used in our compressors. Our KTL-8000 rotary compressor oil, for example, delivers several benefits:

- Outstanding thermal and oxidative stability, giving the air compressor oil much longer life and eliminating oil carryover

- A high viscosity index, enabling it to handle a broader range of temperatures

- A low level of dissolved water, helping prevent corrosion in a compressor’s bearings

- Resistance to oxidation, which can cause varnish or solids to form in the oil

For more information, review the KTL-8000 safety data sheet.

Kaishan’s KTL-8000 rotary air compressor oil.

In short, KTL-8000 is precisely formulated to deliver premium performance, protect your compressor and ensure long life. For more information on the process we went through to specify our air compressor oil, read our blog post, “Choosing the Right Rotary Compressor Oil”.

The next illustration of design integrity is with your compressor’s electronics.

Electronics

Electronics is one critical area where manufacturers differentiate their compressors. And thus make it difficult for aftermarket suppliers to develop components that will work as well as OEM parts.

An off-brand sensor, for instance, might not be as precise as the OEM-specified part. Or, conversely, its parameters might be too tightly calibrated, thereby generating unnecessary alarms.

Variable-speed drives and motors are good examples.

Variable-Speed Drives

VSDs are programmed to communicate with your compressor’s controllers. So, it’s not only about running at the designed speed, but also about the control logic that protects the entire system.

VSDs are a good example of an electronic component uniquely designed to communicate with our compressors’ controllers.

Motors and Grounding

It may seem as if motors would be a reasonably straightforward substitution if you follow everything on the motor nameplate, such as insulation, service factor or framing (NEMA or IEC).

However, grounding can be a significant consideration. For example, some standard motors don’t have grounding for VSD applications. Other manufacturers ground their bearings. Some companies use a grounding brush. And grounding can be critical to the safe operation of a compressor.

Another less-than-obvious example of design intent is with drains.

Drains

What could be simpler than a drain? Unfortunately, even drains are critical elements in compressor design. They need to communicate with the controllers. And many designs have test buttons that enable a technician performing preventive maintenance to pulse the drain and ensure it’s working correctly.

Failing to maintain drains most likely means that you will send moisture downstream. Not a good idea.

Coolers are also a good example of the importance of preserving the designer’s intent.

Coolers

Coolers are a good illustration of the kind of second- and third-tier engineering that matches the capabilities of the components with the sensitivities and settings of the electronics.

On the one hand, your compressor monitors temperatures to ensure you’re only using cooling fans when needed. On the other hand, engineers design our coolers to last the lifetime of the compressor, so they want to minimize thermal stress and fatigue.

So, they constantly balance factors such as operational performance, safety and machine longevity. Those are factors pirated parts can’t take into account, because they’re not designed for a specific machine, the way ours are.

In addition, coolers are designed to work with a specified approach temperature (the temperature of the air coming from the airend, typically 15°F-20°F higher than the ambient air). A non-OEM cooler may be designed for a higher approach temperature, which can cause a greater pressure drop. In a two-stage unit, that might cause the second stage to work harder to overcome the pressure loss.

Another issue for cooler replacement is lead times. For many OEMs, coolers are made by second-tier suppliers, and thus, it takes weeks or months to get a replacement. Kaishan USA, however, manufactures and stocks all our coolers, so our lead times are much shorter. As a result, it’s appropriate to ask about lead times for key components as part of your due diligence when purchasing a compressor.

Water coolers suffer similar problems, either failing to cool the oil to the proper temperature or causing a greater pressure drop than expected.

Next, let’s talk about fans.

Fans

It may seem as if there would be no harm in replacing an OEM fan with an aftermarket model that fits the available space. Once again, that’s not a good idea.

The fans on our air-cooled units are designed to run at specified speeds. Plus, the pitches on their blades are carefully calibrated to generate the required cooling flow. That didn’t happen with a pirated fan.

Even the inlet valve on a centrifugal compressor was designed for a specific application.

Inlet Valves on Centrifugal Compressors

On centrifugal compressors, inlet valves are a critical consideration. Simply swapping out an OEM inlet valve with an off-the-shelf part can alter the valve's performance, potentially degrading it and leading to vibration or damage.

And finally, your compressor’s enclosure panels are also important.

Enclosure Panels

Even repairing or making do with a dented enclosure could have negative consequences. If a forklift, for instance, puts a hole in a side panel, you could lose some of the insulation, not only causing temperature concerns but undermining the noise-dampening function of the panels.

Replacing a damaged side panel with an OEM-specified part should ensure that your compressor retains its decibel rating and complies with hearing protection requirements.

In short, all the parts of your compressor are designed to work together. To see how they do that, download our latest white paper, “Air Compressors 101: How Air Compressor Components, Systems and Parts Come Together to Make Compressed Air.”

Pirated Parts Are Not a Bargain

On paper, it may seem like a good idea to save a few pennies. But you can easily incur thousands of dollars’ worth of damage over the long term, not just in electricity costs, but also in damage to end-use equipment and products.

Clearly, non-OEM parts are not the place to try to save money.

If you really want to save money, reduce your energy costs, cut downtime and improve compressor performance, your local compressed air professional is the place to start.

Why scramble to save pennies on pirated air compressor parts when your compressed air consultant can save you hundreds, if not thousands of dollars?

That’s why we’ve built a nationwide network of independent distributors. These compressed air pros can provide on-site help and consultation as needed, helping you find real savings in your compressed air system. Dwarfing the chump change that you can pick up with pirated parts.

We partner with these independent, local compressed air pros because there’s no better way to serve you. You won’t run into the red tape you find with large corporate suppliers. Just expert guidance, faster response times and personalized support tailored to your needs. You're getting the right system, reliable service and quick access to air compressor parts when you need them. And help in maximizing efficiency and minimizing downtime.

Best of all, when you buy through Kaishan, you're getting a local partner who genuinely cares about your business and wants to see it succeed.

Key Takeaways

- There are several reasons why you should use OEM parts to maintain your air compressor, including improved performance, energy savings, enhanced reliability and longer lifespan.

- The larger topic of design integrity may even be a more important factor in your decision to choose OEM air compressor parts.

- Inappropriate replacement of an air-oil separator can result in fires, explosions and even injuries to workers.

- Kaishan’s KTL-8000 oil is specially formulated to meet the needs of Kaishan compressors.

- Electronics is one clear area where it is challenging for aftermarket suppliers to provide components that perform as well as OEM air compressor parts.

- On paper, aftermarket air compressor parts may look like a bargain, but you can easily incur thousands of dollars’ worth of damage over the long term.

Let Us Help

Obtaining premium OEM parts for your air compressor is crucial to the operation of your compressed air system and all the processes that rely on it. If you need help finding a source for quality OEM components, get in touch with the experts at Kaishan. Contact us today.

Listen to the Podcast Version

The Real Cost of Non-OEM Parts

Alright, welcome back to The Big Dog Podcast. I’m Jason Reed, here with Lisa Saunders, and today we’re getting into something that, honestly, I see way too often—folks thinking they’re saving a buck by going with aftermarket parts for their air compressors. Lisa, you ever hear that line, “It’s just a filter, what’s the worst that could happen?”Oh, all the time. And it’s never just a filter, right? I mean, you swap out an OEM air-oil separator for some off-brand, and suddenly you’re not just risking a little extra oil in your air—you’re talking about real safety issues. Fires, even explosions in the worst-case scenario. That’s not just a scare tactic, it’s happened.

Yeah, and people don’t realize, you’re not just voiding your warranty, you’re basically gambling with your whole system. I’ve seen compressors come in with damage that costs way more to fix than what they “saved” on that cheap part. And the warranty thing—manufacturers aren’t messing around. You use a pirated part, they’ll drop your coverage in a heartbeat.

And it’s not just about the money, either. Like, Kaishan’s air-oil separators, for example—they add a piece of copper on top to make sure the unit’s grounded. That’s not just a nice-to-have. If you get a separator that isn’t grounded right, and a spark happens in the sump, you could have a fire or even an explosion. I mean, it’s rare, but it’s not impossible. Why risk it?

Exactly. And even if you dodge the big disasters, you’re still looking at stuff like oil pass-through, pressure drops, or just plain bad air quality. That’s gonna hit your downstream equipment, maybe even your end product. So, is saving a few bucks really worth risking all that downtime—or worse?

I don’t think so. And honestly, sometimes people don’t even realize what they’re risking. They see a part that “fits” and figure it’s good enough. But if it’s not designed for your machine, you’re just asking for trouble. I mean, would you put bargain tires on a race car and expect to win?

That’s a terrible analogy, but I get what you mean. The point is, you’re messing with the design integrity of the whole system. And that’s where things start to go sideways.

What Makes OEM Parts Different?

So let’s talk about what actually makes OEM parts different. Take Kaishan’s KTL-8000 rotary compressor oil. It’s not just about matching viscosity. The real magic is in the additives—stuff that helps with heat rejection, keeps the oil flowing right, and protects your bearings from corrosion. That’s not something you get from just any oil off the shelf.Yeah, and I’ll tell you, back when I was just starting out, I saw a plant try to save money with an aftermarket sensor. Looked the same, plugged in the same, but it was way off on calibration. Suddenly, the whole production line was getting false alarms, and nobody could figure out why. We lost hours chasing a problem that wouldn’t have existed if they’d just stuck with the OEM part. I mean, I’m not saying every aftermarket part is junk, but you’re rolling the dice every time.

And it’s not just sensors. Variable-speed drives, motors, even the grounding—OEMs design all that stuff to work together. If you swap in a part that’s not made for your system, you could be putting extra stress on the machine, or even creating safety issues you can’t see until it’s too late.

Right, and the thing is, it’s not always obvious. Like, you might not notice a pressure drop right away, or maybe your cooler isn’t working as efficiently, but over time, that’s gonna add up. More energy use, more wear and tear, more headaches. Design integrity and compatibility—they’re not just buzzwords. They’re what keep your compressor running smooth and efficient.

And honestly, if you’re running a plant, reliability is everything. You can’t afford to have your system go down because you tried to save a few bucks on a part that wasn’t built for your machine. It’s just not worth it.

Staying Safe, Staying Efficient

Let’s dig into some of those other parts people don’t always think about—like coolers, enclosure panels, even drains. OEM accessories are designed to fit and perform with your compressor, not just “sort of” work. I remember a Midwest plant that swapped out a drain for a non-OEM one. Looked fine at first, but it didn’t communicate with the controller, so it wasn’t draining properly. Next thing you know, they had moisture running downstream, air quality tanked, and they were down for hours trying to fix it.Yeah, and it’s the same with coolers. If you put in a cooler that’s not designed for your compressor, you might get a bigger pressure drop, or it might not cool the oil to the right temperature. That means your compressor’s working harder, using more energy, and you’re shortening its life. And don’t even get me started on enclosure panels—if you lose insulation or noise dampening, you’re not just making things louder, you could be messing with temperature control and even safety compliance.

And here’s the thing—your local compressed air pro or authorized distributor isn’t just there to sell you parts. They know your system, they can spot issues before they become problems, and they’ll get you the right part fast. You’re not waiting weeks for a cooler to ship from who-knows-where. You’re getting real support, and that’s what keeps your compressor running at its best.

Random stat or

customer quote

textXXtext

text