The Eight Key Components of a Rotary Screw Compressor

March 26, 2025

Four Key Steps to Extend the Lifespan of Your Rotary Screw Compressor with Proper Lubrication

April 9, 2025Three Reasons Rotary Screw Air Compressors Win at Cost

Kaishan USA | April 2, 2025| Uncategorized

Applications such as electronics, semiconductors, food and beverage, healthcare and medical devices need high-quality, oil-free compressed air.

Despite the fact that they may not be the alternative offering the lowest initial cost, rotary screw air compressors have several compelling advantages that give them the lowest total cost of ownership in most industrial applications.

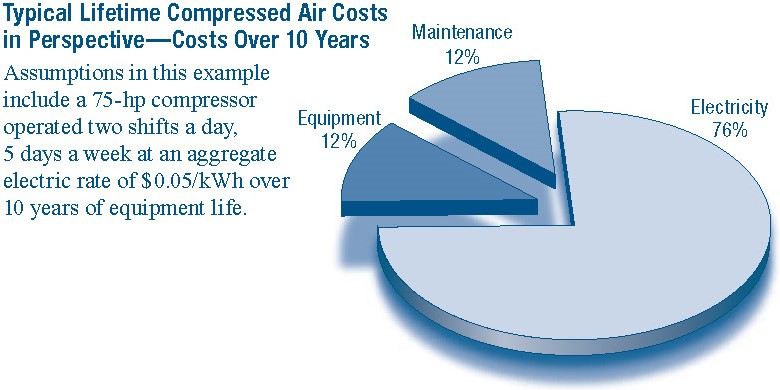

You may indeed pay more upfront. However, most companies today find that the sticker price is less than 20% of the TCO of owning a compressor. That is supported by a U.S. Department of Energy study from 2000, which placed the cost of buying and installing an air compressor at only 12% of lifetime costs, with electricity gobbling up 76% of the total cost of ownership. Maintenance costs made up the remaining 12%.

According to the U.S. Department of Energy, the initial expense to acquire and install the equipment is only 12% of the lifetime cost. On the other hand, electricity makes up 76% of a compressor’s total cost of ownership.

Clearly, focusing on initial cost while ignoring energy efficiency, maintenance costs and long life is short-sighted. Those are the three areas where rotary screw compressors shine.

We’ll start with energy efficiency.

1. Best Overall Energy Efficiency with Variations in Demand

Rotary screw compressors deliver more compressed air per horsepower, giving you more power than other types of compressors for most applications (especially in the 300-600 HP range). They have a simple, time-tested design that enables impressive efficiency and are well-equipped to handle variations in demand.

Rotary screw air compressors work best with a 100% duty cycle. We recommend that you operate them as close as possible to full load. Reciprocating compressors, by comparison, need time to cool down and can only operate 30 minutes in an hour.

In addition to using energy efficiently, rotary screw air compressors have low maintenance costs.

2. Less Maintenance

Rotary screw air compressors have relatively few moving parts and, as a result, are less costly to maintain. They have long service intervals and can run for years before they require a major overhaul. In addition, Kaishan compressors are designed to allow easy access to all major components. That’s because we design them with end users in mind.

For some of our customers, maintaining their air compressor system has almost become a competitive advantage. After all, reducing compressed air loss from the average 40% to 50% range to 20% or less can save them tens of thousands of dollars annually in energy costs. That gives them a leg up on competitors incurring compressed air waste of 50% or more.

A related issue is their long life.

3. Reliable/Robust Long Life

Rotary screw air compressors are durable and long-lasting, and many continue to produce compressed air efficiently for years if not decades. Plus, they are known for reliability and dependability, which translates into less downtime.

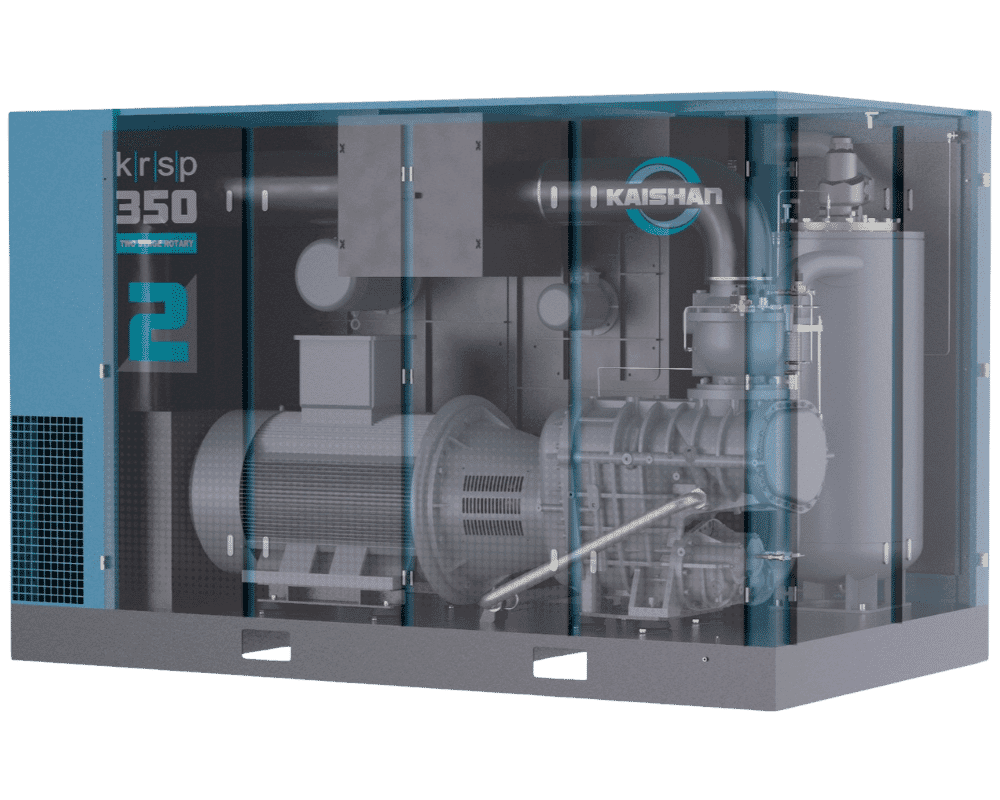

As a result, rotary screw compressors have better warranties than other compressor models. In fact, Kaishan backs its KRSP and KRSP2 rotary screw compressors with a lifetime warranty on the airend.

We back our KRSP and KRSP2 rotary screw compressors with an unmatched lifetime airend warranty.

In addition to their energy efficiency, low maintenance and long lifespan, rotary screw air compressors offer several other benefits.

Other Advantages

Rotary screw air compressors offer several other advantages that may not directly impact TCO, but make life easier for compressed air system operators:

- Steady air flow. Rotary screw air compressors are known for generating steady streams of high-quality air, free of impurities, moisture and the pulsations that sometimes occur with other types of compressors, especially reciprocating or piston compressors.

- Versatility. Rotary screw compressors respond quickly to changing demands, unlike other compressors that take time to ramp up pressure and flow. In addition, they are better than other compressor types at meeting the needs of end-use applications that require high horsepower levels (up to 600 HP). And they can withstand extreme weather conditions and rugged industrial environments. (However, you will need to adjust service intervals to allow for dirty and dusty conditions.)

- Less vibration, quieter. Rotary screw air compressors create less vibration and noise and are quieter than other types of compressors.

- Easy installation. Because they have low vibration, rotary screw air compressors do not need to be bolted down. In fact, we recommend that they not be bolted down, especially if they are installed on a floor that's not level.

- Connectivity. It’s easy to connect them to smart factory and factory automation systems or even link them into their own control system. For example, Kaishan equips its KRSP and KRSP2 premium rotary screw air compressors with a Modbus-compatible control system, allowing them to work with almost any communications protocol. As a result, they are fully compatible with virtually any remote monitoring system.

For a complete review of the advantages of rotary screw air compressors, visit our blog post, “The Top 20 Benefits of Rotary Screw Compressors for Industrial Use.”

The good news is that those advantages add up to a very low total cost of ownership. The better news is that there are many ways to make them even more TCO-friendly. We offer 10 ways below.

Ten Ways To Drive TCO Even Lower

1. Size It Correctly

Sizing may be the most crucial decision you make when you’re buying a new air compressor. Time and again, experience has shown that the most serious air compressor problems arise from mistakes in sizing or application. With rotary screw air compressors especially, that means oversizing. Or over-buying. Trying to add more “muscle” to your system or anticipate future needs.

It may seem counterintuitive, but with rotary screw air compressors, “too much” is almost as bad as “not enough.” So, it’s essential that you don’t oversize your system. For more information on how to size your compressor correctly, download our white paper, “Demystifying Air Compressor Sizing."

2. Consider the Whole System

Your air compressor doesn’t work in a vacuum (pun intended). It’s part of an interconnected system of dryers, storage tanks and piping that delivers the compressed air flow needed at the pressure your end-use applications require.

For more on how all these parts need to work together to deliver what you need where you need it, read our blog post, “Ultimate Guide to Rotary Screw Air Compressor System Design, Part One: 10 Important Questions To Get You Started.”

3. Add a Variable-Speed Drive If It’s Right for You

Many companies have saved money and energy, operating more efficiently at part-load conditions using rotary screw compressors equipped with variable-speed and variable-frequency drives.

But they work best for applications running between 30-70% of capacity. For help in deciding if VSDs are right for you, see our blog post, “How Variable-Speed Drive Rotary Screw Air Compressors Save You Money.”

4. Invest in a Two-Stage Compressor

By dividing the compression cycle into two steps, a two-stage model such as Kaishan’s KRSP2 premium rotary screw air compressor will generate up to 15-20% more flow in the same size air compressor, resulting in a payback that will recoup the price difference quickly.

Kaishan’s KRSP2 two-stage rotary screw air compressors are some of the most energy-efficient machines on the market.

5. Use An Oil-Free Compressor, But Only If You Need It

Many applications require oil-free compressed air, such as food and beverage, electronics, healthcare and medical devices.

However, if you are not in those industries, you may be able to save significantly with an oil-flooded rotary screw air compressor that can service a variety of other uses, such as air tools, grinders and impact wrenches, pneumatic equipment and material handling.

A rotary screw air compressor can even be equipped with filtration that can bring oil levels down to 3 PPM—not good enough for food or semiconductor applications. But it is acceptable for a wide range of other uses.

If you do need oil-free air, you now have two new oil-free alternatives offering compelling new advantages:

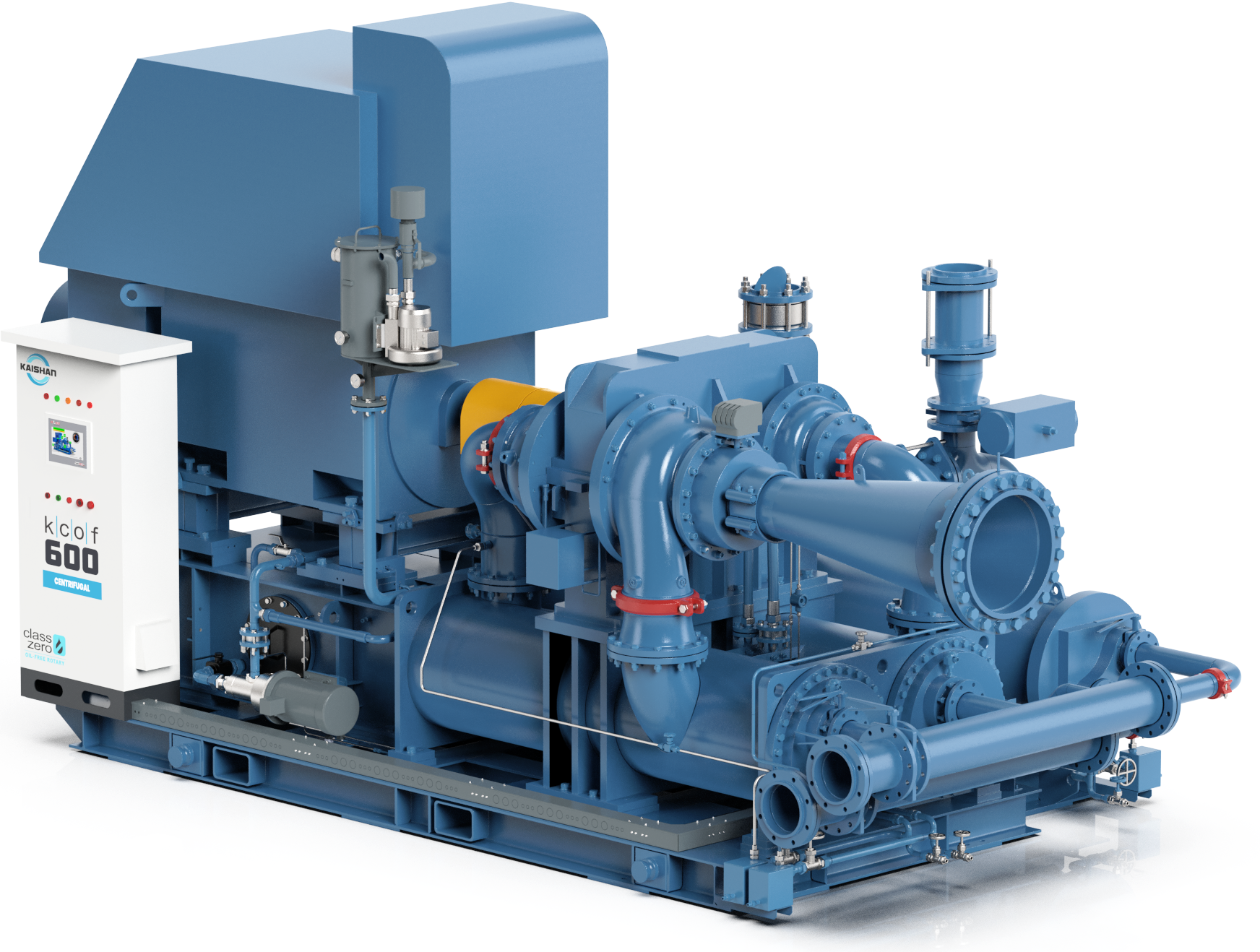

- The KROF two-stage oil-free compressor sets new standards for reliability, efficiency and warranty protection.

- The KCOF centrifugal compressor offers significant control capabilities, low maintenance and support benefits.

Kaishan’s KCOF centrifugal compressor ranges from 250 HP and 1,400 CFM to over 10,000 HP and 50,000 CFM.

For help evaluating whether you need an oil-free compressor, read our white papers, “12 Tips for Optimizing Your Compressed Air System for Semiconductor Applications” and “Breaking Barriers: Think Differently About Front-End and Back-End Food Processing with Oil-Free Compressors.”

6. Add a Backup

It always helps to have a backup, as our distributor Dakota Fluid Power did in this installation.

We often encourage customers to adopt at least a three-compressor approach involving base, trim and backup units.

- A base load compressor to meet your system’s minimum compressed air load.

- A trim compressor to handle fluctuations in demand above the base unit.

- A backup compressor on standby if a base or trim unit goes offline.

Configuring your compressed air system in this way virtually eliminates unplanned downtime, the most avoidable expense associated with your compressed air system. For more information on using a multiple-compressor system to eliminate downtime, see our blog post, “Four Reasons Your Plant Needs a Backup Air Compressor.”

7. Install It Properly

In more moderate climates, like the southeastern and southwestern states of the United States, you can locate an air compressor outside if you protect it from the elements. However, indoor locations are preferable. The compressor should sit on a concrete floor that is flat and level and can handle the unit’s weight. Do not bolt down.

Ideally, your air compressor should be in a dry, well-lit, cool and dust-free room with a maximum ambient temperature of 104°F-115°F. For more on finding the best location for a compressor, see our blog post, “How To Design And Prepare For an Industrial Air Compressor Installation.”

For information on compressor room design, read our blog post, “Compressor Room Design.”

8. Add Heat Recovery

In northern climates, it’s possible to save significant amounts of energy by recovering the heat removed from the compressed air system in the winter. According to Compressed Air Best Practices, you can recover up to 90% of the heat removed from your compressed air system.

Rotary screw air compressors can be equipped with systems to recover heat that ultimately can be used in applications such as water heating, drying or warming food. Even space heating.

For more information on configuring your compressed air system to maximize heat recovery, see our blog post, “Compressor Room Design.”

9. Set Header Pressure as Low as Possible

Many operators set the system pressure to the level required by the tool or tools needing the most pressure. And we get it, you don’t want complaints. However, in most cases, those high-pressure applications make up only a fraction of your system’s applications. And that means you are over-pressurizing everything else. Significantly.

That wastes energy, especially if your plant needs 80 PSIG and you're compressing up to 125. A crucial part of operating your compressed air system is setting the header pressure as low as possible.

For a complete discussion of setting your system pressure, visit our blog post, “How Lowering the Pressure Band of Your Compressed Air System Can Save You Money.”

10. Develop a Maintenance Program

If you want to keep your new air compressor running reliably and efficiently for decades, take air compressor maintenance seriously. Industry research has shown that a proactive maintenance strategy can help you reduce maintenance costs by as much as 70%.

We strongly recommend that you follow your original equipment manufacturer’s maintenance guidelines to maintain the integrity of your air compressor system and allow it to achieve the performance level you expect.

For the critical air compressor maintenance steps you’ll need to address regularly, see our blog post, “What You Need to Know About Rotary Screw Compressor Maintenance.”

Start with an Audit

An audit by a compressed air professional can help system operators optimize their systems and reach a level of compressed air performance that will elevate them above the competition. It can save time and money, improve reliability, ensure higher quality air, extend equipment lifespan and improve system performance, all of which add up to a lower TCO.

To find out how your company can benefit, download our white paper, “How An Air Compressor Audit Can Help You Build Competitive Advantage.” You’ll see that an audit gives your air compressor professional a chance to assess your operation and recommend ways in which new technology can boost compressed air performance, lower operating costs and improve air quality.

But that all starts with your compressed air consultant.

The Help You Need to Get the TCO You Want

We believe the best way to achieve the air compressor performance you want is to work with a local compressed air professional. That is why we have developed close relationships with a nationwide network of independent distributors, who can deliver the right systems, reliable service and quick access to parts when you need them most

We believe that's the best way to ensure you have expert advice, fast response times and personalized support tailored to your needs. They have factory-trained techs who know industrial applications. And know how to maximize efficiency, minimize downtime and get the parts when you need them. You're getting more than a product—you're getting a local partner who cares about your business and wants to see it succeed.

Key Takeaways

The three main TCO advantages of a rotary screw air compressor include:

- Efficiency

- Long life

- Reliability

The 10 ways to lower your TCO include:

1. Size it correctly.

2. Consider the whole system.

3. Add a variable-speed drive if it’s right for you.

4. Invest in a two-stage compressor.

5. Use an oil-free compressor, but only if you need it.

6. Add a backup.

7. Install it properly.

8. Add heat recovery.

9. Set header pressure as low as possible.

10. Develop a maintenance program.

Let Us Help

Lowering your total cost of ownership is one of the primary benefits of adding a rotary screw air compressor to your facility. Sized and installed correctly, it will give you years of efficient, reliable service, allowing you to optimize the operation of your compressed air system and all the processes that rely on that system. If you need help determining how to lower the TCO of your compressed air system, get in touch with the experts at Kaishan. Contact us today.

Listen to the Podcast Version

Why Rotary Screw Compressors Excel

Welcome to the Big Dog podcast! Where it's industrial air compressors, all the time.Let's dive right in. Industries like electronics and healthcare, they rely on oil-free compressed air—it's not just a preference, it's mandatory. We're talking about environments where even the smallest contaminant can cause product failures or, worse, serious safety issues.

Right, and oil contamination… that would be a nightmare for something like semiconductor manufacturing or medical devices, yeah?

Exactly. And that’s why rotary screw compressors have become the go-to. Their design ensures a steady stream of high-quality air, totally free from impurities and moisture. It's this consistency that makes ’em perfect for industries with no margin for error.

Okay, but what about the practical side? I mean, aside from the air quality, what’s making rotary screw compressors outperform other options?

Energy efficiency is their big selling point. They deliver more compressed air per horsepower compared to other types. Plus, they’re built for a 100% duty cycle. That means they can work continuously without needing downtime to cool off. Your average reciprocating compressor? Can’t handle more than half an hour of work at a time.

Oh wow, so no cooldown breaks. That’s a huge edge for factories running 24/7. But what about maintenance? I’d imagine that level of performance would mean a lot of upkeep?

Surprisingly, no. Rotary screw compressors have fewer moving parts, which means less can go wrong. Maintenance intervals are long, and major overhauls? Not something you’ll be dealing with for years. Plus, manufacturers like Kaishan specifically design these units with ease-of-maintenance in mind.

Okay, I’m sold. But do you have an example—like a real-world use case that shows these benefits in action?

Definitely. There was this manufacturing facility—they were running into constant issues with downtime from older piston compressors. Switched to a rotary screw system, and not only did they see fewer breakdowns, but their energy costs dropped significantly. They also cut air leakage by half, which saved them tens of thousands annually.

Wait, saved tens of thousands? Just from reducing leaks?

Yeah. Air leaks are silent profit killers. And rotary screw compressors are way better at minimizing that loss. It’s all about efficiency, reliability, and keeping operations running as seamlessly as possible.

Reducing Total Cost of Ownership

Alright, so you’ve convinced me rotary screw compressors are efficient, reliable, and great for minimizing losses. But now let’s tackle the big question on everyone’s mind—cost. Where does the biggest investment go, and how do the savings stack up?Good question. Most people think it's the upfront cost, but that’s way off. According to a U.S. Department of Energy study, the initial expense of buying and installing a compressor? It’s only about 12% of the total lifetime cost. The real wallet-drainer here is electricity—taking up a whopping 76% of that TCO pie.

Whoa. So energy usage is the giant here. Does that mean energy efficiency should be the main priority to keep costs down?

Exactly, and that’s where rotary screw compressors shine. There are a few ways to tackle this efficiently. For one, adding a variable-speed drive can be a game changer. It adjusts the compressor’s output to match demand, which means you’re not wasting energy when operations slow down.

Okay, I know variable-speed drives are popular, but do they work for every setup?

Not necessarily. They’re best for systems running at something like 30 to 70% capacity most of the time. If you're running full tilt all day, a fixed-speed compressor might actually be more efficient. It's really about knowing your workload.

Got it. And what about the system pressure? I’ve heard that lowering that can help with energy savings too, right?

Yep. Most operators set their system pressure higher than needed, just to avoid complaints. But cranking everything to 125 PSI when your equipment only needs 80 PSI? That’s just throwing money away. Dropping to what’s actually needed can drive huge energy savings, no question.

That’s wild, because it sounds so simple. But what about heat recovery? I know some industries are starting to catch on to that.

It’s true, and it’s underrated. You can reclaim up to 90% of the heat generated by the compressed air system. That heat can be used for space heating, warming water, even drying processes. Think northern factories pumping out heat in the winter—it’s not just savings, it’s smart recycling.

Okay, so let’s make this real. Do you have an example of a company that’s knocked it out of the park with these strategies?

Actually, yeah. There’s this beverage firm—total energy-hog setup before. They were running oversized compressors, way too much power for what they really needed.

Let me guess—they switched to the right-sized rotary screw compressors?

Exactly. They right-sized their system, added a variable-speed drive, and optimized their pressure settings. Energy costs dropped by almost 20%. We’re talking thousands saved every year, just from dialing it in properly.

That’s the kicker for me. It’s not always about throwing money at the problem—it’s about being smart with the setup. Rotary screw compressors let you do just that. And that’s where they prove their worth time and time again.

Beyond Efficiency: Maintenance and Longevity

Speaking of cost-saving strategies, let’s dig into maintenance. People tend to underestimate just how much proper upkeep can save you—it’s not flashy, but it’s critical. A solid maintenance strategy can cut long-term expenses by, what, 70%?Seventy percent? That’s… actually kind of shocking. So you’re saying most of those surprise costs—the breakdowns, the inefficiencies—they’re totally avoidable?

Absolutely avoidable. By sticking to the manufacturer’s guidelines, staying proactive instead of reactive, you’re gonna save yourself a lot of headaches—and cash. Take Kaishan’s KRSP and KRSP2 compressors, for instance. They’re built to last. Long service intervals, minimal wear. And that lifetime warranty on the airend? Kinda speaks for itself.

Right, reliability plays a huge role here. When your system’s not breaking down all the time, you’re not just saving on repair costs—you’re keeping operations running smoothly, which has its own benefits. But let’s dig into audits for a second. Why are those so crucial?

Good question. A professional audit’s basically like sending your system back to school. It looks at inefficiencies—air leaks, improper pressure, oversized equipment—and tells you where you’re wasting money. Fix those, and you’re tackling inefficiencies before they spiral. It’s one of the smartest investments you can make.

Okay, so it’s not just about checking boxes. You’re getting actionable insights to improve your setup, make it leaner and meaner. Do you have any examples of how an audit really pays off?

Actually, yeah. There’s this industrial plant—they brought in an audit and found out their system pressure was way higher than needed. Combined with a few leaks? They were bleeding money. Made the fixes, optimized their settings, and boom—annual savings in the tens of thousands, no exaggeration.

And it seems like these small changes—just dialing things in, keeping maintenance consistent—they really stack up, don’t they?

Exactly. It goes back to building a reliable, efficient system from the ground up. When you’re thinking long term—not just the upfront costs—you start seeing the real value. Rotary screw compressors deliver that, time and time again.

Well, on that note, I think we’ve covered a lot today—efficiency, cost, longevity, and everything in between. That’s a wrap on this episode of The Big Dog Podcast. Thanks for listening!

And don’t forget, keep it efficient, keep it running. Catch you next time.

Random stat or

customer quote

textXXtext

text