The Role of Air Compressor Intake Filters

February 12, 2025

Everything You Need to Know About Air/Oil Separators

February 26, 2025Ultimate Guide to Rotary Screw Air Compressor System Design, Part One: 10 Important Questions To Get You Started

Kaishan USA | February 19, 2025| Uncategorized

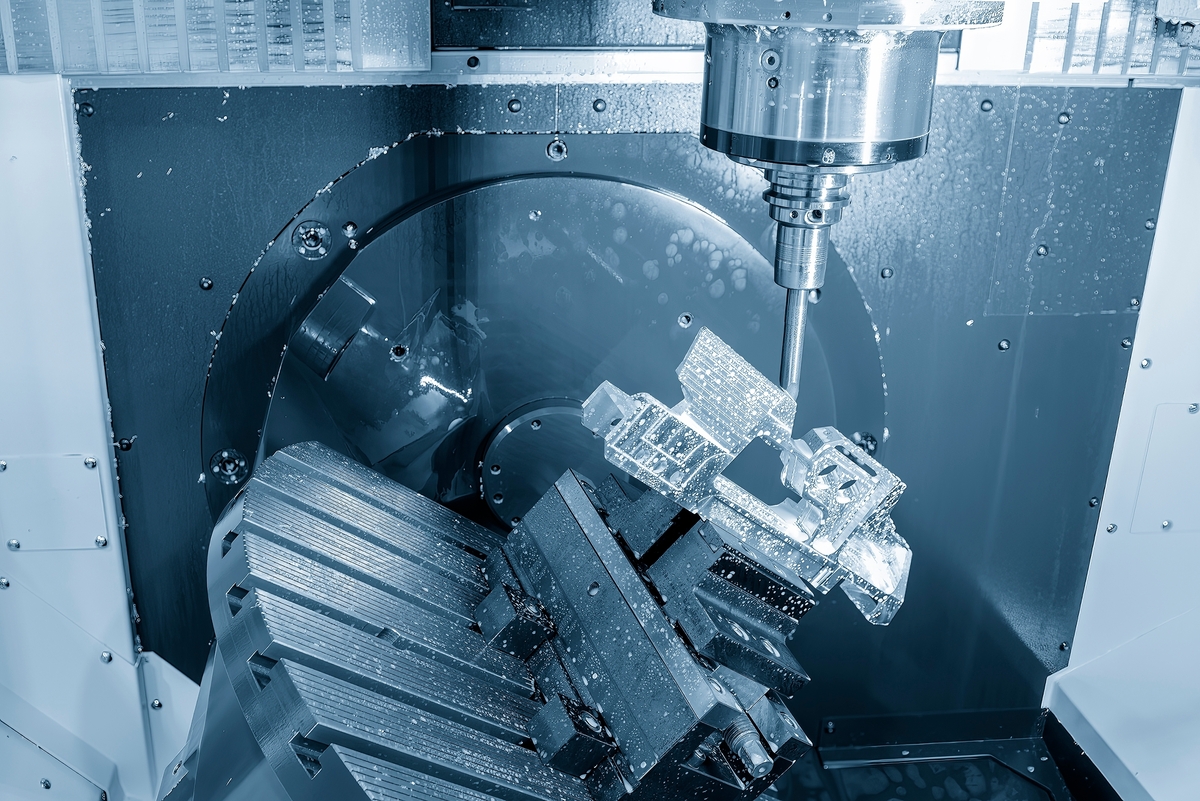

Pure air is so important to million-dollar CNC machining centers that they often have built-in pre-filters to screen out any additional impurities.

Specifying and buying an air compressor has become quite a challenge. Largely because compressed air system design has so many moving parts.

To help you better understand all those considerations, we’ve compiled the first ten questions you’ll want to consider as you go down the road of air compressor system design.

We’ve organized these initial questions into four main categories: the situation, your demand profile, onboard equipment and support equipment.

And look for part two of our series on compressed air system design topics.

Let’s start with your situation.

Your Situation

1. Do You Need an Oil-Free Compressor?

Are your products ultimately consumed by humans? If you’re in the food, pharmaceutical or healthcare industries, you probably need an oil-free rotary screw air compressor. Similarly, if you’re in the semiconductor or electronics industry, you should also go oil-free.

If you apply coatings or finishes that would be marred by even the tiniest oil droplets contained in the air from oil-flooded rotary screw air compressors, you also want to be oil-free. The same is true of million-dollar CNC machines, which even have pre-filters built in to ensure their compressed air is pure.

Oil-Free Options

We offer two oil-free options:

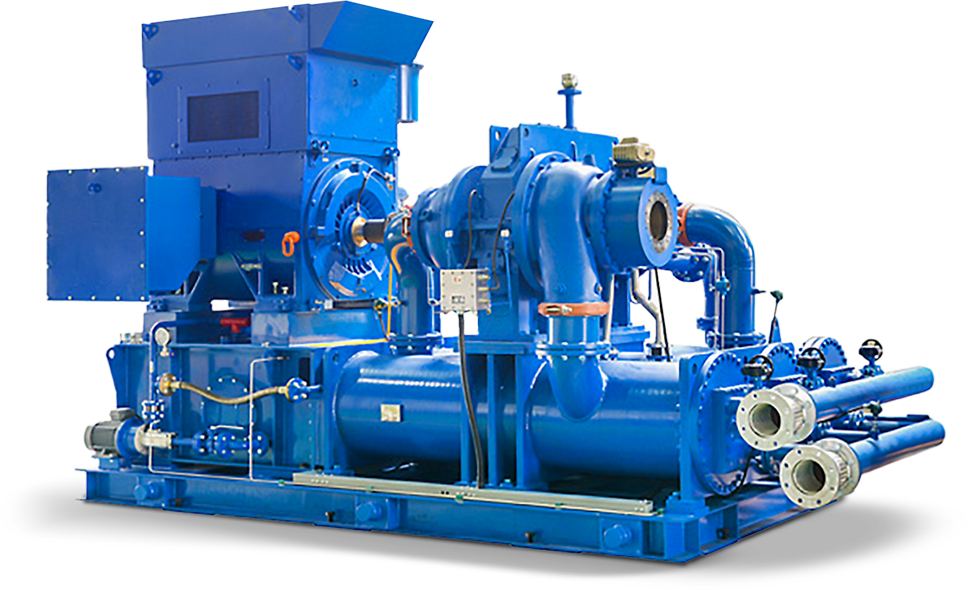

- The KROF two-stage oil-free compressor sets new standards for reliability, efficiency and warranty protection.

- The KCOF centrifugal compressor offers significant benefits in control capabilities, low maintenance and support.

Kaishan’s KCOF centrifugal compressor ranges in size from 250 HP and 1,400 CFM to over 10,000 HP and 50,000 CFM.

Kaishan’s KROF two-stage oil-free compressor is an excellent choice when you need uncontaminated, highly efficient, reliable air.

Other than that, in the thousands of other industrial and commercial applications of rotary screw air compressors, you may be able to save significantly with an oil-flooded unit. The kind of compressor that can power air tools like grinders and impact wrenches, drive pneumatic equipment and support sandblasting and material handling.

Many industrial applications, especially hand tools like impact wrenches, do not require oil-free air and will benefit from the lower cost, outstanding reliability and long life of oil-flooded rotary screw compressors.

For more information on oil-free air, read our white papers, “12 Tips for Optimizing Your Compressed Air System for Semiconductor Applications” and “Breaking Barriers: Think Differently About Front-End and Back-End Food Processing with Oil-Free Compressors.”

2. Is a Variable-Speed Drive Right for You?

Variable-frequency and variable-speed drives, like those newly offered by Kaishan USA, allow rotary screw air compressors to operate more efficiently at part-load conditions. But they’re not for everyone.

Many companies have saved money and energy, operating more efficiently at part-load conditions using rotary screw compressors equipped with variable-speed and variable-frequency drives.

But they are not for everyone. As noted, they deliver the greatest benefits when you have significant variation in demand. They work best for uses between 30% and 70% of capacity but are not recommended at capacities below 20% or above 80%. And, because they have more significant heat-dissipation challenges, keeping an oil-free unit in the 60-80% range is preferable.

We provide more detail on the benefits of VSDs and VFDs in our blog post, “The Benefits of Installing Variable-Speed Compressors.” And to see some VSD success stories, visit our case studies page.

After determining whether you need a VSD, you can focus on your demand profile.

Your Demand Profile

3. How Much CFM and PSIG Do I Need?

Calculating the pressure and flow your plant needs requires considering all its uses and compiling a demand profile, spelling out how much CFM and PSIG you need and when you need them.

CFM indicates the volume of air you’re using. The abbreviation stands for cubic feet per minute, which specifies the amount of compressed air flowing through your system. Pressure, referred to as PSIG, drives the flow needed for your applications. PSIG means pounds per square inch gauge and measures the system pressure—the force required by your end-use application to perform a task.

Many people find the inverse relationship between flow and pressure confusing: increasing the pressure decreases the flow and vice versa.

For additional information on sizing for CFM and PSIG, check out our blog post, “CFM vs. PSIG: What You Need to Know to Size an Air Compressor.”

4. How Can I Plan for Future Needs?

It’s important that you plan for future needs, like expansions or additions to your capabilities. But be careful: with rotary screw air compressors, too much is as bad as not enough.

Our advice is to purchase what you need when you need it. After all, plans change. Therefore, it's best to buy a compressor that’s appropriately sized for your current needs. If you require more capacity later, buy another unit. By doing this correctly, you’ll build flexibility and avoid the issues of rapid cycling. And you may have some backup if a compressor goes down.

We’ve had situations where a customer who overbought can pay for a new, smaller compressor with the money they’ll save on electricity costs alone. Companies have also lost warranty protection by operating machines at chronically low levels.

For more on this topic, read our blog post, “My Compressor is Rapid Cycling. Now What?"

With compressor sizing issues resolved, let’s talk about the onboard equipment needed.

Onboard Equipment

5. How Big Should the Compressor’s Coolers Be?

The short answer is “big.” To lower the temperature of the air and remove moisture, you need a large cooling capacity.

That’s especially important for oil-free units, where temperatures are much hotter. And it’s why we equipped our KROF two-stage oil-free rotary screw air compressor with oversized coolers.

All too many manufacturers have tried to cut costs by downsizing this critical function. We do things differently. We ensure that all our coolers are sized to handle the load and then some.

6. What Kind of Filtration Do I Need?

You can get different grades of compressed air filters to match the requirements of your application, removing solid particles, liquid water, water and oil vapors, odorants and even bacteria and viruses.

These distinctions are captured in the filter classes established by ISO 8573-1:2010, a standard the international body adopted in 2010. Filters are rated from 1 through 9, plus X, with the lower numbers achieving higher levels of air purity. You’ll want to cascade filters—using coarser filters upstream to catch the larger particles that would prematurely clog a finer filter downstream.

However, the critical consideration for filters is maintenance. Clogged filters will impede and eventually block airflow, causing energy loss that is both unnecessary and avoidable. So, you’ll need to replace filter elements regularly.

For more information on the most important filter in your compressor, the intake air filter, read our blog post, “The Role of Air Compressor Intake Filters.”

Now that we’ve reviewed the cooling and filtration you need, let’s move to support equipment.

Support Equipment

7. How Much Storage Do I Need?

The Compressed Air & Gas Institute (CAGI) recommends up to 10 gallons per CFM and provides a formula to calculate the air receiver size based on time allowed for the pressure drop.

The main point is that the tank should be sized so that the system cycles no more than ten times per hour.

For more on storage, see our blog post, “A Quick Guide to Accurately Size Air Compressor Tanks”.

8. Do I Need Wet or Dry Storage?

Compressed air can be stored “wet” or “dry,” with wet storage tanks located before the air-drying system and dry tanks located after the dryers.

Dry storage's big advantage is that it offers compressed air that is ready for use right out of the tank. It reduces the risk that high-demand events will exceed the air dryer’s capacity.

Wet storage, however, allows excess water and lubricant to condense out of the system before it hits the filter and dryer. It thus increases your air dryer’s energy efficiency and prolongs the life of the pre-filter element. Plus, it eliminates the pressure drop on the air dryer side of the system that occurs with dry storage. Wet tanks are very important for desiccant dryer systems due to the large amount of air used when the towers switch.

We recommend a combination of wet and dry storage, with 20% as wet storage and 80% as dry.

For more on storage, see our blog post, “A Quick Guide to Accurately Size Air Compressor Tanks”.

9. Do I Need Flow Control?

We recommend that most of our customers use some form of flow control. Flow control monitors the pressure at the control valve, releasing air from the air receiver tanks to maintain system stability. Thus, it buffers the compressors from the ups and downs of system demands.

Kaishan USA always recommends using flow control because it allows you to reduce discharge pressure on your compressors and cut energy usage and cost.

Flow control helps you maintain air pressure throughout your plant at the lowest optimum level, reducing artificial demand and increasing energy efficiency. But to make flow control work, you need compressed air receiver tanks.

For more on flow control, read our blog post, “Everything You Need to Know About Compressed Air Controls.”

10. What Kind of Dryers Do I Need?

You can score significant energy savings over the life of your system just by choosing the right type of air dryer for a compressor.

Refrigerated dryers cost less and have lower energy operating costs than desiccant dryers. For most processes, refrigerated dryers are sufficient.

Desiccant dryers provide the driest air for critical applications, but they have higher upfront and energy costs. They are also the best choice where piping is exposed to harsh conditions, such as temperatures below 40°F.

For smaller applications or point-of-use drying, you may want to consider a heatless model because of its lower initial cost.

Questions? We Have Even More Answers!

Doing compressed air system design properly is well worth the effort. Most facilities will benefit from the advice of a compressed air professional in answering these questions and planning for upgrades and improvements to their air compressor systems.

Fortunately, Kaishan can help. We work closely with a nationwide network of independent distributors, who can provide on-site help and consultation. They are skilled in air compressor system design and the operation and maintenance of compressed air systems.

Key Takeaways

- You need oil-free air if your products are ultimately consumed by humans or you’re in the electronics or semiconductor industry.

- If applicable, VSDs can make it more efficient to operate your compressor at part-load conditions, saving you money and energy.

- Compiling a demand profile requires that you consider all compressed air uses.

- While it may seem smart to oversize a rotary screw air compressor to anticipate future needs, our advice is to buy only what you need when you need it.

- Coolers are important because your compressor needs a lot of capacity to lower the air temperature and remove moisture.

- The critical consideration for filters is maintenance.

- CAGI recommends that facilities add up to 10 gallons of storage per CFM.

- We recommend a combination of wet and dry storage, with 20% wet and 80% dry.

- Flow control allows you to reduce discharge pressure on your compressors and cut energy usage and cost.

- Refrigerated dryers are less expensive and require less energy to operate than desiccant dryers and are sufficient for most processes.

Let Us Help

Proper air compressor system design is critical to the operation of your compressed air system and all the processes that rely on that system. If you need help designing a compressed air system that meets your needs, get in touch with the experts at Kaishan. Contact us today.

Listen to the Podcast Version

The Need for Oil-Free Solutions in Critical Industries

Alright, let’s start with the elephant in the room—do you really need an oil-free compressor? I mean, if you’re in industries like food, pharma, or electronics, let’s be real, there’s no question about it. The level of air purity these sectors demand is non-negotiable.Right, because even trace amounts of oil contamination can ruin an entire batch. And in those industries, the stakes are enormous. Imagine a single contaminated bottle at a pharmaceutical plant—

Or worse, a chip in the electronics space. Seriously, oil-free systems are almost like insurance policies for their production lines.

Exactly. And I was reading a case about Dell’s manufacturing facilities. They use oil-free compressors extensively because it’s critical to protect the delicate components during the production process. One slip, and you’re looking at not just damaged products but—

Major financial losses. Yeah, their approach makes total sense. It’s all about preventing reliability issues upfront rather than cleaning up a mess later.

And not to mention the reputation hit. Consumers and B2B customers expect perfection from industries like these. Purity isn't optional; it's an expectation.

You’d think that would be obvious, yet some facilities cut corners. And what happens? Downtime. Contaminants clogging up machinery or worse, entire systems failing. It can all spiral out of control fast.

That’s why it’s so surprising when companies neglect these solutions. They might look at the higher upfront cost of oil-free systems and hesitate, but the long-term savings more than make up for it, don’t you think?

Absolutely. Oil-free compressors are more than just a piece of equipment—they’re a failsafe. And with newer options, like Kaishan’s models, efficiency and reliability come built-in. That’s a no-brainer for me.

But what about operations that stick with oil-flooded units? Have you ever seen those situations play out?

Too many times. They save a few bucks upfront and then spend double or triple later fixing the fallout. It’s, well, it’s the classic penny-wise, pound-foolish move. And don’t get me started on how much downtime cuts into productivity.

Which is why having the right tool for the job—like oil-free compressors for these critical industries—makes all the difference.

Maximizing Efficiency with Variable-Speed Drives

Speaking of choosing the right tools for the job, let’s dive into Variable-Speed Drives. They’ve been absolute game changers for so many facilities. By matching compressor output to demand, especially in part-load conditions, they offer a level of efficiency that wasn’t possible before.Right, but they’re not for everyone, are they? They’re most effective when there’s a lot of variability in demand, between, what, 30 to 70% of capacity?

Exactly. If your operation is consistently above 80% or below 20%, they’re not gonna do much for you. And, uh, heat dissipation can become a challenge too, especially with oil-free setups.

So, it’s all about matching the technology to your actual needs. That’s where demand profiling comes in, right?

Spot on. Creating an accurate demand profile is vital. You need to map out your pressure and flow needs—those are your CFM and PSIG metrics. These numbers tell you how much compressed air you’re using and the force necessary behind it. Without that, it’s basically guesswork.

But isn’t there sometimes confusion about the relationship between pressure and flow? Like increasing one can decrease the other?

Yeah, that’s one of those counterintuitive things. Increasing pressure reduces flow and vice versa. If you don’t keep that balance in mind, you could end up overcompensating and driving up energy costs.

Ouch. And energy efficiency is a huge deal these days. So, once you’ve nailed down your demand profile, what’s the next step—sizing the compressor?

Bingo. But here’s the trap—people either go too big or way too small. Oversize it, and you’re wasting energy and money. Undersize it, and your production suffers. I always tell people, buy for the now, not the maybe.

Makes sense. And if your needs change later, it’s not like you can’t add another unit, right?

Exactly. That modular approach not only adds flexibility, but it’s also a safety net. If one unit goes down, you’ve got backup. Plus, you avoid rapid cycling, which, let me tell you, kills compressors and wrecks warranties.

So there’s really no upside to going overboard early on. It’s about playing the long game with smart planning.

Exactly. Efficiency isn’t just about the equipment; it’s about using it wisely.

Effective Maintenance Strategies and System Optimization

Speaking of using equipment wisely, let’s talk about something that’s just as critical as setup—maintenance. Specifically, air filters. Lisa, you’d be shocked how many facilities I’ve seen skimp on this essential step.Oh, I can imagine. But isn’t it one of those things where the costs of skipping filter maintenance show up later in, like, energy bills or worse, damaged equipment?

Exactly. A clogged air filter doesn’t just cut airflow—it forces everything to work harder. That means higher energy use, more wear and tear, and eventually, breakdowns. I mean, would you drive your car for years without changing the oil?

No way. And the cost of replacing a filter is peanuts compared to fixing or replacing an entire compressor.

Right, yet some places just let them sit there, clogged to oblivion. It’s mind-boggling.

Alright, so regular filter changes are a no-brainer. What about storage? I’ve heard a lot of debate about wet versus dry setups.

Yeah, and here’s the thing—both have their place. Wet tanks are great for letting excess water and lubricant condense out before they hit your dryers or filters. But dry storage is clutch when you need air that’s ready to go instantly. A good system splits it—like 20% wet storage, 80% dry. Anything else, and you’re asking for inefficiencies or even system failures.

So, it’s a balance, then. But what happens if someone doesn’t calculate their storage needs properly?

Then you’re looking at tanks that either cycle too often—wasting energy—or ones that can’t keep up with demand spikes. Either way, it leads to downtime or even damaged system components.

And downtime’s the worst. I mean, that’s literally money burning away. Speaking of keeping systems stable, how does flow control fit into all this?

Ah, flow control, the unsung hero of air compressor systems. It stabilizes the pressure by releasing air from the storage tanks only when needed. Without it, guess what happens? You get pressure drops, inefficiencies, and overworked compressors trying to play catch-up.

So basically, it’s another layer of protection against unnecessary energy loss.

Exactly. And every bit of energy you save adds up big time in the long run. So, keep your filters clean, balance your storage, and get proper flow control. You do that, and you’re already miles ahead of most operations.

Well, that sounds like solid advice to me. I mean, it’s really about being proactive, right? Keeping things running smoothly before they become problems.

Nailed it. Maintenance isn’t exciting, but it’s what separates the efficient facilities from the ones constantly dealing with downtime and repair bills. Simple choices, big impact.

Alright, Jason, I think we’ve covered some critical ground today—from the needs of oil-free compressors to optimizing with VSDs and now these maintenance best practices.

Absolutely. It’s all about making smart, informed decisions and sticking to them. The benefits are clear.

And on that note, that’s all for today, folks. Thanks for joining us on another episode of The Big Dog Podcast.

Yup, and don’t forget—efficiency starts with you. Catch you next time.

Random stat or

customer quote

textXXtext

text