How to Choose the Best Air Compressor for Optimal Aviation Operations

November 22, 2023

Air Compressors in the Food Industry: Pneumatic Solutions for Quality and Safety

December 13, 2023Which Types of Air Compressors Work Best for Metallurgy Industry

Kaishan USA | November 29, 2023 | Uncategorized

Air compressors provide air for many different metallurgical applications, including blast furnaces.

Air compressors are used widely throughout the metals and metalworking industries, providing a reliable, consistent fourth utility (joining electricity, gas and water) in challenging environments.

Applications include:

- Air supply. Air compressors provide air in blast furnaces, coke production and oxygen furnaces.

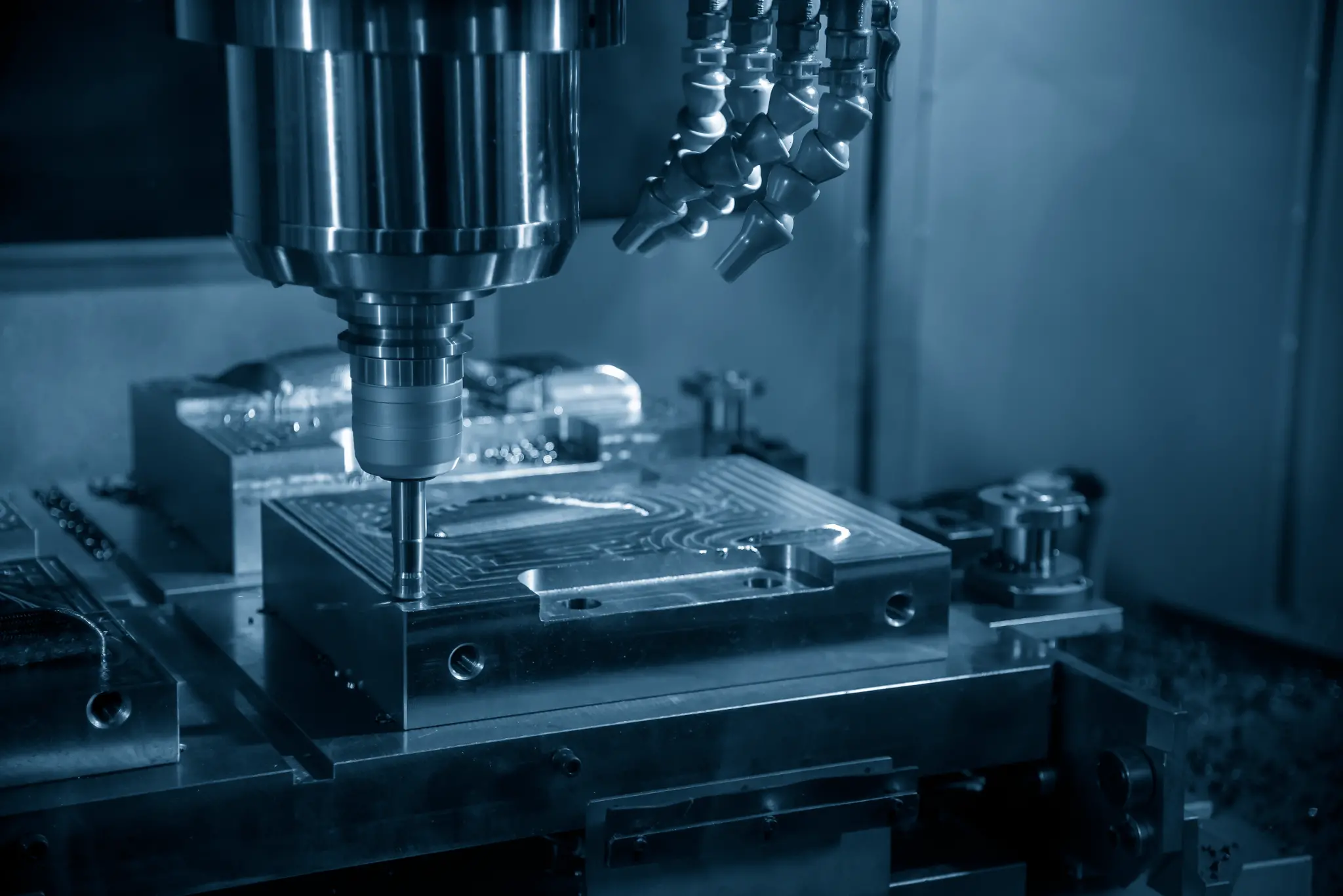

- Power. Air compressors are a power source for forming, mold presses and injection molding. They also drive pneumatic tools like grinders, sanders, impact wrenches and drills.

Air compressors supply the power that allows a CNC machine to create molds for injection molding.

-

- Finishing. Metalworking companies use compressed air in painting, powder coating and electroplating.

- Controls. Pneumatic actuators demonstrate proven reliability, controlling automated systems, machines and processes in less-than-ideal circumstances.

Powder coating of metal products relies on compressed air.

In addition, metalworking operations deploy compressed air systems in more mundane applications like cleaning, descaling, spray painting and maintaining bag houses.

The high temperatures and dusty, dirty air common in metalworking facilities create challenges for air compressors.

A Challenging Environment

The typical metalworking operation is a challenging environment for an industrial air compressor. The ambient air is often dusty and dirty, loaded with conductive materials from welding and other processes.

In addition, high temperatures characteristic of metalworking environments create special problems for an air compressor. Its cooling system works harder, reducing the compressor’s capacity and increasing the temperature of discharge air. The hotter discharge air means your dryer does not work as efficiently.

Hotter air is also thinner, so your compressor produces less air flow (CFM). That makes your system work harder to maintain header pressure. And the air carries more water, making life tough on air dryers. The common rule of thumb is that the moisture holding capacity of saturated air doubles for every 20°F rise in temperature.

That’s why it’s so important to choose the right type of compressor for your application.

Types of Compressors

There are many different kinds of compressors, but, facilities use one of three main types for the most part: reciprocating, centrifugal or rotary screw compressors. Each offers some unique benefits, depending on the application:

-

- Reciprocating compressors. A reciprocating piston compressor acts like an automobile engine, drawing air into a compression chamber as it moves in one direction, then compresses it when it reverses and moves in the opposite direction. A recip is inefficient and has a limited duty cycle, so it is not for every application. Many customers find they are very noisy as well.

- Centrifugal air compressors. Centrifugal compressors, also called dynamic compressors, create compressed air by increasing the air’s velocity using an impeller then slowing it with a diffuser. Extremely efficient, especially at high volumes, centrifugal compressors can produce a lot of air from a small footprint and are very durable. Unfortunately, they are usually large (thousands of HPs) and have a limited pressure range; they are sold in multi-stage designs to get to pressures above 100 PSIG.

- Rotary screw compressors. Rotary screw compressors have two rotors that rotate through a compression chamber and pressurize the air until it reaches the desired pressure. They range in size up to 700 HP. Because they have fewer moving parts, rotary screw compressors are more reliable than other types of compressors. They can handle a 100% duty cycle—we recommend setting up your compressed air system so that they operate as close to full load as possible. In addition, they are very energy efficient and good at variations in demand. Best of all, they deliver high-quality air, meeting the needs of a wide variety of aviation applications, especially for electronics and painting.

Generally, a centrifugal air compressor is most cost-effective for high-volume applications (above 2,500 CFM). A reciprocating compressor is the best choice for low-volume applications (less than 20 CFM). But rotary screw air compressors are the best for everything in between. For more on the subject, read our blog post, “Which Type of Air Compressor Is Best for Your Application?”

Even metalworking operations with large facilities will do better with multiple rotary screw compressors than with a single centralized industrial air compressor.

Rotary Screw Air Compressors—the Best Choice for Most Metalworking Applications

Because of their reliability, efficiency and long life, rotary screw air compressors are the industrial air compressors of choice for most applications. Even major manufacturers with thousands of employees usually select rotary screw machines because their facilities are too large to make centralized units practical. In addition, rotary screw air compressors are known for producing steady streams of high-quality compressed air and handling large-capacity loads. And they are backed by the industry’s best warranties—Kaishan’s KRSP and KRSP2 screw compressors are backed by a lifetime warranty on the airend.

Kaishan’s KRSP and KRSP2 screw compressors are backed by an unmatched lifetime airend warranty.

Application Tips

You can get the most out of your rotary screw air compressor by following a few simple application tips.

1. Right-Size Your System

Be careful not to oversize your system. It may seem counterintuitive, but with rotary screw air compressors, “too much” is almost as bad as “not enough.”

Here’s why. Screw compressors are designed for a 100% duty cycle. Run them significantly less than that, and you’ll waste energy, reduce equipment lifetime and perform more maintenance.

Do not try to size your compressor with “room to grow.” If you need help sizing your system appropriately, contact your local air compressor consultant.

2. Lower Your Pressure Band

Most compressors use load/no load controls, sometimes called online/offline. With this approach, you set a load pressure and an unload pressure, such as 115 PSIG and 125 PSIG, respectively.

That gap of 10 PSIG (pounds) is called the pressure band. The goal is to keep your compressor from loading and unloading too fast because starting and stopping too often increases thrust loads, reducing bearing life. And it can exceed the maximum starts per hour on electrical components, specifically the inrush current on the motor

But if you have two or three compressors that aren't tied into each other electronically, you could be loading at 110 PSIG and unloading at 120 PSIG on one machine. With another at 115 to 125 and the last at 120 to 130 PSIG.

That’s a lot of wasted energy, especially if your plant needs 100 PSIG and you're compressing up to 130. The rule of thumb is that for every 2 PSIG increase in pressure, the energy consumption goes up by 1%. You can conserve energy by setting the header pressure as low as possible.

3. Avoid Rapid Cycling

Unfortunately, the transition between the load and no-load states mentioned above does not occur as rapidly as we might like. It takes several seconds for the internal pressure to be relieved. During that time, your air compressor may switch back into the loaded state before the transition to the no-load state is complete. If that happens too frequently, it can lead to rapid cycling, which causes increased wear and reduces compressor reliability and lifespan.

To combat rapid cycling, we often propose modulation that adjusts the inlet valve to a partially open position. While modulation has traditionally been viewed as a waste of money and energy, you have to balance that potential cost with the negatives of rapid cycling. It’s not out of the question to see a compressor with a ten-year expected life cycle fail after just six months of rapid cycling.

Variable speed drives are a more energy-efficient way to address this issue but cost more up front. Neither modulation nor VSDs take the place of an appropriately sized compressor and storage tank, however. It’s the best practice to have both wet and dry storage to remove moisture and maintain stable header pressure for these fast events.

While VSDs can save money in the right application, you should be aware of the challenges posed by the typical metalworking operation. Dust, dirt and airborne contaminants could clog the VSD’s heat exchanger, causing it to overheat. As a result, we do not recommend VSDs where the unit would be near a welding operation, for example. which adds conductive material to the ambient air.

Maintenance Is Critical

Because of the challenging environment in a metalworking facility, you’ll want to take some essential maintenance steps to counteract the heat:

-

- Air flow. Make sure all vents are open. Verify fans are functioning if used for moving air in your equipment room. When you walk into the room, does it feel hot? If so, you need to improve the air flow.

- Heat exchangers. Make sure your heat exchanger coils are clean and free of dust and debris.

- Filters. Inspect air filters every 4,000 hours, replacing them as needed. We recommend changing oil filters every 2,000 hours of operation or as indicated by a change in pressure readings.

- Drains. The increased moisture in the air means more water must be removed from the system, most of which ends up in the drains. Inspect the moisture trap drain and the drains in all your tanks, filters and dryers.

- Sampling. Changing the compressor oil and sending out a sample for testing every 2,000 hours not only safeguards the compressor against potential heat-related issues, but also significantly reduces downtime and repair costs.

- Stop leaks. Compressed air systems lose between 30% and 50% of their volume to air compressor leaks, with poorly maintained systems running as high as 80%. As a result, one constant task is determining how many leaks you have. And estimating how much you can save by fixing them. For more information on fixing links, see our blog post, “How to Find and Stop Air Leaks.”

How Kaishan Helps

We have taken several steps to ensure our rotary screw air compressors do well in even the most challenging environments. Major enhancements include:

-

- Oversized coolers. Kaishan owns and operates its own cooler manufacturing facility, allowing us to design and even oversize our units to handle hotter environments. We design most of our coolers to withstand temperatures as high as 122°F, while many of our competitors list 104° to 115°F as their maximum temperatures.

- Oversized coolers. Kaishan owns and operates its own cooler manufacturing facility, allowing us to design and even oversize our units to handle hotter environments. We design most of our coolers to withstand temperatures as high as 122°F, while many of our competitors list 104° to 115°F as their maximum temperatures.

Kaishan oversizes coolers on most of its line, including this KRSP100 premium rotary screw air compressor to accommodate ambient temperatures of 122°F (50°C).

-

- Spacious packaging. We also design our packages to be more spacious with more air flow. Spacing out the internal components allows them to cool more efficiently. As a result, our compressors are not the most compact on the market, but they handle temperature extremes better than machines with tighter spaces. And they’re easier to service.

- Robust lubricants. Kaishan's OEM lubricants have undergone rigorous testing in a range of extreme environments, from the frigid polar regions to the scorching heat of deserts, ensuring their resilience and efficiency. This proven performance record makes Kaishan's OEM lubricants a trusted choice for reducing downtime and increasing operational productivity, regardless of temperature.

Local Help

Kaishan USA works with a nationwide network of independent distributors, who can provide on-site help and consultation as needed. These factory-trained air compression experts have an investment in their local communities and can service your air compressor system without a problem. And they have staff members who are skilled in advanced technology on a daily basis.

Key Takeaways

-

- Air compressors are used widely throughout the metals and metalworking industries.

- High temperatures and dusty, dirty air create challenges for air compressors in metalworking facilities.

- Rotary screw air compressors are the industrial air compressors of choice for most applications.

- Maintenance of a rotary screw air compressor is essential because of the challenging environment.

- Kaishan equips its reliable rotary screw air compressors with oversized coolers to help them withstand the heat.

Let Us Help

Selecting the right air compressor, sizing it properly and installing it correctly are critical to the operation of your compressed air system and all the processes that rely on that system. If you need help choosing the right air compressor for your metalworking operation, get in touch with the experts at Kaishan. Contact us today.

Random stat or

customer quote

textXXtext

text

Air compressors are used widely throughout the metals and metalworking industries, providing a reliable, consistent fourth utility (joining electricity, gas and water) in challenging environments.