How to Find and Stop Air Leaks

November 23, 2022

Innovation in the Air Compressor Industry

December 7, 2022Ultimate Air Compressor Buying Guide for Automotive Facilities

Kaishan USA | November 30, 2022 | Uncategorized

Compressed air systems have played an important role in automotive manufacturing since the earliest days of the industry.

Compressed Air for Automotive Facilities

Compressed air has played a major role in the development of automobile manufacturing almost since the industry’s inception. Compressed air systems help automakers build key components, assemble and move heavy objects, fasten parts in place and even apply glossy finishes.

Even more significantly, air compressors play a part at all levels or tiers of the industry, from the major carmakers themselves to their huge network of suppliers. And even to aftermarket operations like repair shops, body shops, collision centers, tire sales outlets and the like.

Let’s take a closer look.

Compressed Air Throughout a Tiered Industry Structure

The automotive industry with its hundreds of thousands (maybe even millions) of suppliers, has a tiered structure designed to organize all the players and keep the car companies from being overwhelmed.

At the center of the structure is the major car companies, who are called original equipment manufacturers (OEMs). A very small group of tier one suppliers, who sell major assemblies like seats, drivetrains and body assemblies is permitted to sell directly to the OEMs. It’s a small club, deliberately designed to meet the specific needs of the car companies.

In successive concentric circles around lower tiers, each of whom buys from the tier “below” them and sells to the tier “above” them. Tier three component makers, in other words, buy from tier four materials suppliers and sell to tier two sub-system manufacturers.

The key idea is that all the players stay in their lane. tier three suppliers sell to tier two. That’s it. No going around the tier twos to try to win favor with tier ones.

All that is relevant to air compressor companies because each of the different tiers has specialized needs:

- Tier four suppliers make materials, from plastics to aluminum, to steel, that are used to make the parts and components that go into a car. For the most part, their products are not innately designed for automobiles, although their higher-tier customers will specify certain grades of products. Aluminum alloys in the 5000 and 6000 series, for instance, are used for automotive parts, including body paneling, fuel tanks, steering plates, and piping. Because the category is so broad, these companies use compressed air in all kinds of applications, depending on the processes employed.

- Tier three suppliers make parts, like door handles, steering wheels, lug nuts and windshields. As with the tier fours, these companies could supply the same or similar products to other industries. A machine shop making handles or latches for automotive use could also be making those products for other applications, from boats, to planes, to bicycles. From a compressed air point of view, they use the kinds of hand tools, machining centers and conveying equipment that any general manufacturing operation requires.

- Tier two suppliers make larger sub-assemblies. Think door panels, dashboards and window glass. These suppliers generally are specialized for automotive applications. Their use of compressed air systems not only powers machines and hand tools, but also pneumatics applications.

- Tier one suppliers like Faurecia, Dana or Lear, make major systems, like seats or drivetrains. Tier ones run the gamut of compressed air applications with lots of hand tools used in fitting, tightening and attaching components into systems.

- Original equipment manufacturers assemble the final product, combining a lot of major systems that come from the tier ones, with a few elements, like engines, that they design and build in-house. The pieces they build themselves are the parts they feel differentiate them from their competitors. They use air compressor systems like conveyors and robotics to lift large parts into place and attach them. Think of a car door being lifted into place and attached to the car body.

Conveyors help move heavy parts through the automobile manufacturing process.

So while only a few air compressor manufacturers sell large automotive air compressors to the original equipment manufacturers like the largest automakers, the entire air compressor industry sells its products to the other tiers in the automotive supply chain.

And, lest we forget them, there’s an entire automotive aftermarket of tire centers, body shops and repair shops that service our cars after we buy them.

Auto repair shops usually have air compressors performing a variety of functions.

Major Automotive Industry Issues

Compressed air systems help the industry address some of its key issues, including improving fuel economy and reducing weight, reducing downtime, and achieving the mirror finishes the car-buying public so loves.

Light Weight

The U.S. National Highway Traffic Safety Administration’s Corporate Average Fuel Economy (CAFE) standards establish fuel consumption standards for most vehicles. For the most part, the automotive industry has focused on reducing the weight of its products, using lightweight materials. Think fabrics, aluminum and plastic.

Compressed air is present in all of those activities, but especially in plastics, where pneumatics is employed to create myriad small plastic parts. And even in powering the molding of larger components.

Reducing Downtime

Global automotive companies like Ford, General Motors, Toyota and BMW usually have huge centrifugal compressors powering hundreds of applications throughout their factories. Those highly engineered systems are optimized to handle day-to-day operations efficiently.

There are, however, occasions where smaller rotary screw air compressors are employed as backup or trimming industrial air compressor units to meet specialized needs.

Even more than its versatility across the factory floor, compressed air is known for its reliability, an important consideration in an industry where an hour of downtime costs $1.3 million. At those rates, an extremely reliable rotary screw air compressor, deployed as a backup, could literally pay for itself in minutes.

Clean, dry air is critical for painting operations, whether they’re in an automotive assembly plant or a local body shop.

Higher Quality Air

OEMs, body shops and collision repair centers all need high-quality, clean, dry air to power their grinding and painting operations. They don’t want moisture, oil, dust, or other impurities to mar their paint jobs. Usually, they need to have high-quality air compressor dryers and compressed air filters. And maintain them scrupulously.

Noise Levels

Some tier two and tier three suppliers rely on piston machines, which can be loud when you have more than a few compressors. They usually find rotary screw air compressors are much quieter, an important consideration as the U.S. Center for Disease Control (CDC) estimates that 46% of manufacturing employees are exposed to hazardous noise levels.

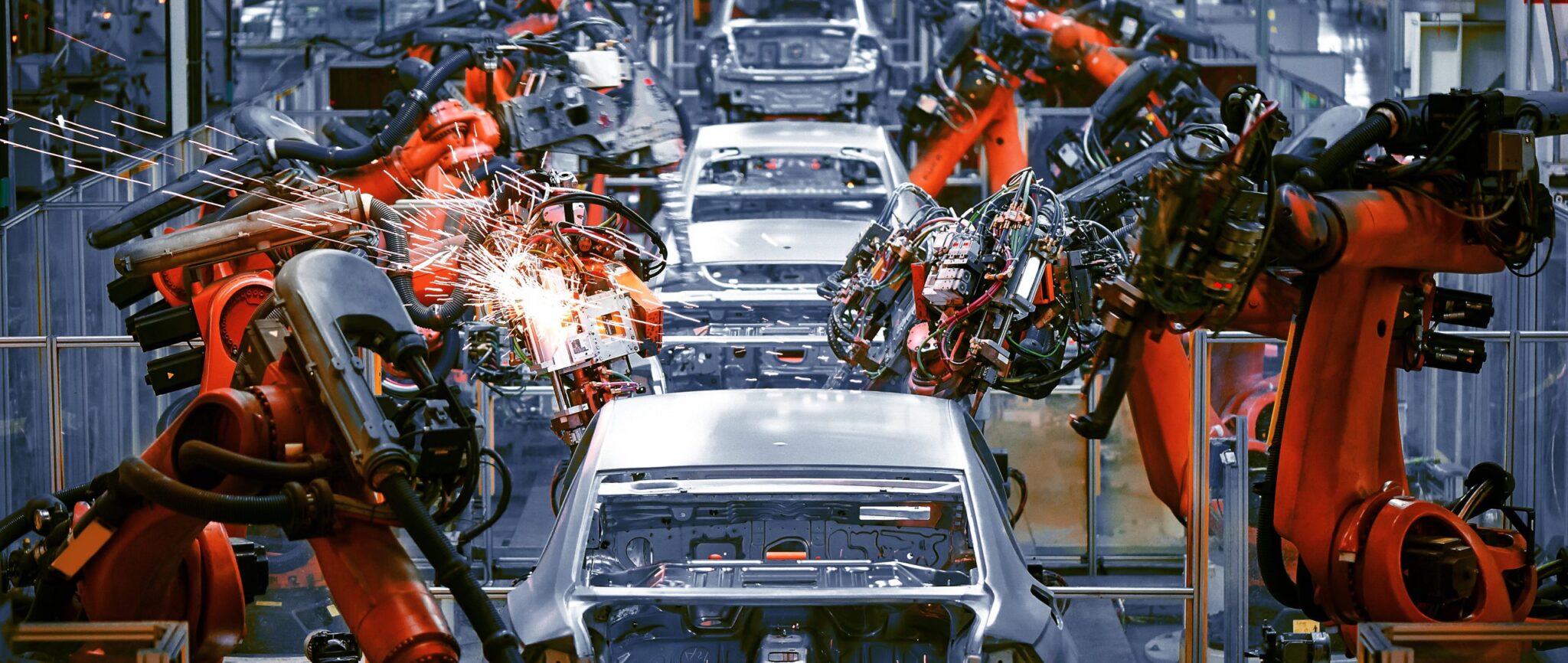

Automotive assembly plants increasingly use robots throughout the manufacturing process, lifting heavy objects in place.

What Goes Where

Compressed air powers the robotic arms that often do the heavy lifting in assembly plants, grabbing engines and transmissions and placing them on the chassis. Ditto with quarter panels, door pillars, side panels and roof pieces.

Meanwhile, anywhere finishes are applied, clean, high-quality air helps the OEMs as well as aftermarket body shops and collision centers achieve the rich, lustrous finish we all prize on our vehicles.

And while we think of robotics and large conveyor systems mostly going to the larger OEMs and maybe the tier one companies, you’ll find other air-driven products, like ratchet guns and torque wrenches, at almost any level in the automotive supply chain.

The Right Technology

And while other technologies like hydraulics or electric drive units provide valuable energy and power sources to the automotive industry, compressed air systems make a unique contribution in providing power for specific applications. Other technologies simply can’t match compressed air for its reliability, safety, convenience, and light weight.

Key Takeaways

-

- Compressed air systems are found throughout the automotive industry, including all tiers.

- Air compressors help all the players achieve major objectives like reducing weight, cutting downtime and generating high-quality air.

- Air-driven pneumatics plays a key role as automakers move to plastics reduce weight and improve the fuel economy of their vehicles.

- The reliability of rotary screw air compressors such as those offered by Kaishan USA helps auto companies avoid costly downtime.

- High-quality air filters and dryers help carmakers get the clean, dry air they need.

Let Us Help

If you are in the automotive industry, at any tier or aftermarket and you’re looking for ways to improve the reliability and performance of your compressed air system, we can help. From belt-driven, single-stage and two-stage rotary screw air compressors to centrifugal compressors and industrial vacuum pumps, we have what you need. Get in touch with the experts at Kaishan. Contact us today.

Random stat or

customer quote

textXXtext

text

Compressed air has played a major role in the development of automobile manufacturing almost since the industry’s inception.