Adams Direct & Media Services

June 20, 2025

Henkel

June 23, 2025CASE STUDY:

KAISHAN USA CUTS “OH, SHI—” MOMENTS, HELPS CORNERSTONE CUT $25,000-PER- HOUR DOWNTIME

The Situation

One of America’s largest manufacturers of exterior building products, Cornerstone Building Brands makes vinyl siding products at its Jasper, TN plant. Compressed air drives most of the filling and production feed equipment at the plant, which produces $25,000 worth of products in an hour.

“If we lose air, we lose the plant,” said maintenance manager Konnor Kruse. “The plant can’t run.”

The Challenge

In the first “Oh, shi—” moment, a new compressor’s main drive failed after 900 hours of service. The unit was down for eight months while the vendor waited for parts, with rentals costing $30,000 monthly. Then, after it was back in service, a second moment occurred: the main motor went out, and the vendor estimated repairs at $130,000.

In addition to the constant repairs, the unit was only reaching 95-97 PSIG in pressure, well short of Cornerstone’s needs. “Our basic requirements weren’t being met,” Konnor said.

The Solution

At the suggestion of Sid Green, his maintenance planner and scheduler, Konnor connected with Clay Broadus in the service department at Air & Hydraulic Equipment, an independent Kaishan distributor in nearby Chattanooga. Clay fixed the ailing unit for a fraction of the estimated cost, then worked with Konnor to find a permanent replacement.

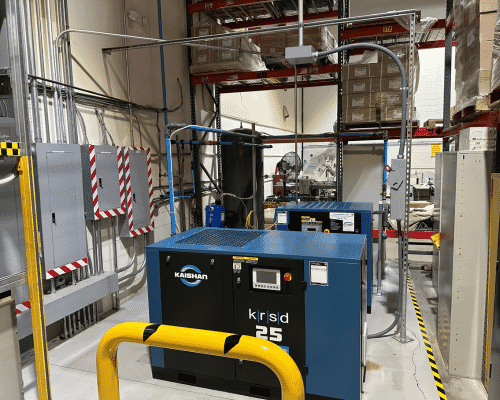

Konnor said he was looking for increased capacity and wanted a reliable, efficient, heavy-duty compressor with good performance. Clay played a significant role in his decision to purchase a 350-HP Kaishan KRSP2 premium rotary screw compressor with a variable-speed drive, Konnor said.

The Results

- THE BEST ENDORSEMENT: CRICKETS: The new unit has performed flawlessly, Konnor said, ending the shutdowns and rental costs the company suffered with the other units. With service and support from Clay and Air & Hydraulic Equipment, Konnor said his team has not had to touch the Kaishan unit. “That’s the best endorsement you can get. When you’re accustomed to a major catastrophe once a year or even more frequently and you get a new compressor in and there’s ‘crickets,’ that’s a good thing. The result speaks for itself.”

- SAVINGS ON ELECTRICITY COSTS: The VSD helps the Kaishan deliver electricity savings, although Cornerstone has not quantified them.

- TACKLING OTHER TASKS: The Kaishan unit not only reaches the 110-PSIG pressures the plant needs but also handles a few unplanned-for tasks, including blowing water off the vinyl before it is packaged. “We have more capacity to do that,” Konnor said.

- “RELIABLE” OPERATION: The new unit has been a morale boost for the troops with the greater compressed air pressure allowing his coworkers to be more efficient. “Just not getting frustrated with equipment that’s not working to their standards,” Konnor said. “And also, from a safety standpoint, you’re dealing with a nail gun, so you have more pressure. You have less likelihood that you fire that gun and something goes awry.” Konnor’s success in replacing the failing units has proved to be a feather in his cap as well, giving him the credibility to suggest other upgrades in Cornerstone’s manufacturing infrastructure.

“That’s the best endorsement you can get. When you get a new compressor in and there’s ‘crickets,’ that’s a good thing. The result speaks for itself.”

— Konnor Kruse, Maintenance Manager, Cornerstone Building Brands

More case studies:

Random stat or

customer quote

textXXtext

text